PP Woven Bag Sack for Packing

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 Pieces pc

- Supply Capability:

- 2000000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

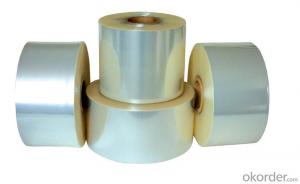

Introduction of PP Woven Bag Sack For Packing

1. full line of production.

2. strict quality control

3. 10 years experience.

4. efficient communication.

5. quick delivery.

Specifications of PP Woven Bag Sack For Packing

Raw Material |

100% new pp or client's option |

Color |

All kinds of color, client's option |

Printing |

With/without, client’s option |

Width |

From 750px-3750px [ two sides 30-2000px] |

Length |

According to the customer’s requirement |

Weights/m2 |

60gmto 150gm |

lamination |

with/without, client's option |

Packing |

100 pcs/bundle ,1000pcs/bale or 2000pcs/bale,packed by pp wrapped fabric |

Business information OF PP Woven Bag Sack For Packing

Minimum Order |

20,000pcs |

Delivery Time |

15~30days after place an order |

Payment Term |

L/C, T/T (30% deposit and 70% balance after faxing the B/L copy in 3days) |

Quantity in Container:

20ft container: 11~12 tons, 150,000pcs ~220,000pcs

40ft: 22~24 ton 300,000pcs~450,000pcs.

40H ft: 24~26ton, 330,000pcs~480,000pcs.

We has been exported to the following countries :

Asia:South korea, Uzbekstan, Pakistan ,Japan , Philippines, Malaysia, Vietnam Oman ,Jordan , Israel, Sudan Saudi Arabia

America:Canada, Mexico.

Oceania:Australia, New Zealand

Africa:Egypt,South Africa, Nigeria, Botswana, Algeria, Kenya

Europe: Romania, Italy ,Germany, Hungary

South America:Brazil, Peru, Chile, Honduras

Advantage OF PP Woven Bag Sack For Packing

1) Products is made of the natural material.

2) The quality of product meet with the international standards , has been exported to more than 20 countries.

3) We can also provide you free samples if you need, the buyer should bear express charge.

4) On time communication, quick delivery, best service. We hope to set up long-term business relationship with you.

- Q: What is the material of detergent bag?

- Polyethylene (polyethylene, referred to as PE) is a thermoplastic resin made by polymerization of ethylene. Industrially, it also includes copolymers of ethylene with a small amount of alpha olefins. Polyethylene is odorless, non-toxic, feel like wax, has excellent resistance to low temperature performance (minimum temperature up to -100~-70 degrees C), good chemical stability, erosion resistance to most acid-base (not resistant to oxidizing acid). At room temperature, insoluble in general solvents, low water absorption, good electrical insulation.

- Q: How do I remove the self-adhesive label affixed to the plastic bag?

- On the label with wind, a few minutes to unveil the label, the label will fall together with adhesive. Even at the stubborn stickers with traces of essential balm, and fingernails pull, usually can quickly clean up the traces.

- Q: Is the packet in the food package a reducing agent or an oxidizing agent?

- The small bag inside the food package is an antioxidant. Belongs to reducing agent.

- Q: What is the material for edible fungus stick packing bag?

- High pressure polypropylene bag, the bag has the characteristics of high temperature and high pressure, it can reach 120 degrees and not easily deformed. It is the first choice for factory cultivation.

- Q: What are the requirements of the mark on the cement packing bag?

- The cement packing bags shall clearly indicate the standards of implementation, cement varieties, codes, strength levels, producers' names, production licence marks (QS) and serial numbers, serial numbers, date of packing and net contents. Bags on both sides should be based on the varieties of cement with different color printing name and cement strength grade, Portland cement and ordinary portland cement Portland slag cement by using red, blue gray volcano; Portland cement and Portland fly-ash composite silicate cement by sleep and black or blue..

- Q: What are the advantages and disadvantages of OPP and CPP membranes? What kind of bags are they used for?

- CPP films have the characteristics of good transparency, high gloss, good stiffness, good moisture resistance, good heat resistance, and easy to heat sealing. CPP film is printed and bag made

- Q: What kind of material is the express package on the market now? It's dark in the outer grey.

- The materials used for express bags are generally HD-PE, which can be recycled and can be re packed into bags

- Q: Is the color of cement packing bags related to cement?

- Bags on both sides should be based on the varieties of cement with different color printing name and cement strength grade, Portland cement and ordinary portland cement Portland slag cement by using red, blue gray volcano; Portland cement and Portland fly-ash composite silicate cement by sleep and black or blue.

- Q: What can be easily removed from the words printed on plastic bags?

- Plastic packaging is printed on the word if it is ordinary ink with thinner a wipe off, is not easy to erase the organic dye. Such dyes are colored substances. But a coloured substance is not necessarily a dye. What kind of dyes do you use on plastic bags?.

- Q: How many kinds of packing bags are there in the packaged foods?

- The material is generally PE and PP.Compared with non food packaging, it does not contain plastic additives, and will not release toxic substances during use. For example, the more severe plasticizer in the front can cause cancer, and is used in PVC packaging. PVC used in the past, but because of its insecurity, it is now being gradually replaced by PE plastic wrap.

1. Manufacturer Overview

| Location | Shandong, China (Mainland) |

| Year Established | 2008 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Northern Europe South Asia |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | qingdao |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | Low and/or Average |

Send your message to us

PP Woven Bag Sack for Packing

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 Pieces pc

- Supply Capability:

- 2000000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches