Multilayer PET or MPET Laminated With Craft Paper Bag for Packing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of Multilayer PET or MPET Laminated With Craft Paper Bag for Packing:

Multilayer PET or MPET Laminated With Craft Paper Bag for Packing are processing with imported materials,we have introduced advanced equipment and high manufacturing technology into production lines and we have rich experience in producing plastic bag .can meet your needs by fulfilling your specification in a positive manner .High efficiency and speed are our working style .high quality and competitive price are our pursuit.

Multilayer PET or MPET Laminated With Craft Paper Bag for Packing mainly used for packing food such as coffee, tea, snack, powder etc.

2. Main Features Multilayer PET or MPET Laminated With Craft Paper Bag for Packing:

Excellent quality control

Experienced facotry produced

SGS passed

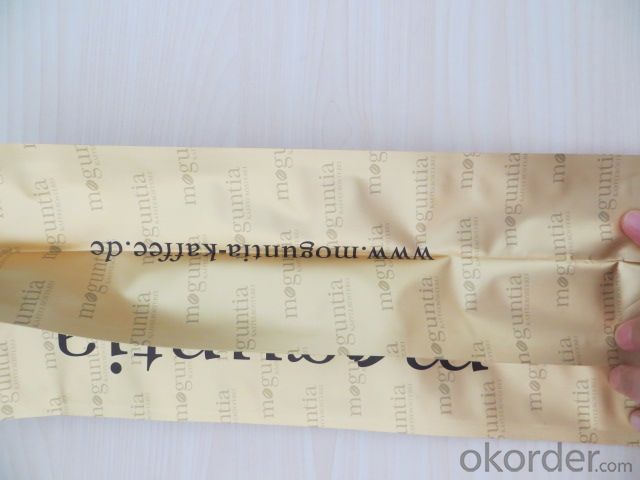

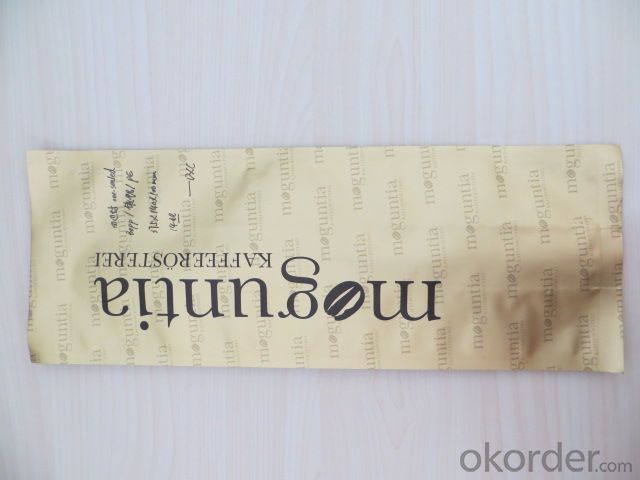

3. Multilayer PET or MPET Laminated With Craft Paper Bag for Packing Photos:

4. Multilayer PET or MPET Laminated With Craft Paper Bag for Packing Specification:

1. Material: PE,LDPE,HDPE with Craft paper etc

2.Size:10*10000px or Customized

3.Thickness:10-200um

5.FAQ of Multilayer PET or MPET Laminated With Craft Paper Bag for Packing:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Plastic packing bags can supply you all kind of packing bags you wanted.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Express carton packaging, plastic packaging should be how to deal with?

- For those cartons, environmentalists have their own ways of using them. "The Jingdong loves to use plastic bags, and Amazon and its customers prefer cartons."." Some of the more orderly carton, you can keep as a storage box. You can use the marker pen to write the contents on the carton, then stack it on the bottom of the cupboard to improve the space utilization. For some cartons that cannot be used for the time being, use the tape on the carton to flatten the cartons.

- Q: What does "TM" mean in a food package?

- Its role is to tell people that it is marked by the graphics or text of the goods or services of trademark, not the name is not advertising. English and "R" is the abbreviation of "register", "register" Chinese means "registered", goods or services on the mark that is told people, it marked the graphics or text but not trademarks, and registered trademarks, protected by law, unauthorized, unauthorized use can not be any other individuals and organizations.

- Q: What is the material for edible fungus stick packing bag?

- High pressure polypropylene bag, the bag has the characteristics of high temperature and high pressure, it can reach 120 degrees and not easily deformed. It is the first choice for factory cultivation.

- Q: How are food bags made out?

- Copperplate etching: that is, according to the design confirmation of the food packing bag, the copperplate needed for the food packing press is made. The version is a cylinder, and is a set of not a single root, the specific size, the number of versions, according to the previous package design to determine. One color has to make a copperplate, if there are 5 colors, you have to do 5 copperplate, of course, sometimes can also be common edition.

- Q: What are the bags and bags?

- According to the material classification as follows: laser aluminum film, re paper materials, laser transfer paper materials, paper composite materials, aluminum composite materials, plastic composite materials, fabric composite materials.

- Q: What about the use of plastic bags?

- There are advantages and disadvantages. If it is a new material, the printing ink is also non-toxic. You can use it safely. If you use recycled materials, there is a foul smell. That's bad. What's more, we will bring plastic bags to the cooked food, it is best to buy from the supermarket, come back after the food will be taken out, to avoid food and plastic bags long-term exposure, chemical reaction products. That's bad for your health.

- Q: What kind of material is the express package on the market now? It's dark in the outer grey.

- The materials used for express bags are generally HD-PE, which can be recycled and can be re packed into bags

- Q: The shelf life of the package usually takes several forms

- Name of commodity, ingredient, product standard number, production license, date of production, shelf life, method of use, storage conditions, origin, manufacturer and address.

- Q: What are the types of composite packaging bags?

- Folding general transport packing bagA package of bags weighing 0.5-100 kilograms, mostly woven from plant fibers or synthetic resin fibers, or a multi layer material package made of several flexible materials. For example, straw bags, bags and other cement sacks. - mainly packaging powders, granules, and individual small items.

- Q: How many kinds of packing bags are there in the packaged foods?

- PE's softness and mechanical properties are worse than those of PP. It represents shopping bags, plastic wrap, garbage bags and so on.PP is stiffer, anisotropic (with a notch that is easily ripped), has good mechanical properties, and is superior to PE in high-temperature performance, representing bread bags.I wonder if this answer has met your requirement.

Send your message to us

Multilayer PET or MPET Laminated With Craft Paper Bag for Packing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches