LC LOW CARBON FERRO CHROME FECR ALLOYS MANUFACTURER SUPPLY

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ferro Chrome

Chrome is always used to improve the antioxidation and corrosion resistance of steel to make the surface of steel after it is oxidized to form strong adhension oxide film. Then it stops being oxidized or decelerates being oxidized.Micro-Carbon ferro chorme is applied to making stainless, acid-resistant steel and heat resistant steel.

Chrome is mainly used to improve the antioxidation and corrosion resistance of steel to make the surface of steel after it is oxidized to form strong adhension oxide film. Then it stops being oxidized or decelerates being oxidized. Micro-carbon ferro chrome is applied to making stainless steel, acid-resistant steel and heat resistant steel.

Specifications

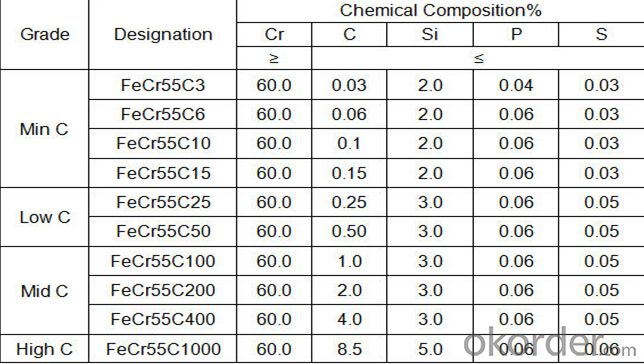

Low Carbon Ferro Chrome

1. Original manufacturer

2. The stability of the shipments

3. Free samples

4. Relatively lower cost

Products information

1. It can be used to produce FerroChrome and Chrome metal in metallurgy industrial.

2. As a kind of steel addition,it is used to produce various special steels with high strength,corrosion resistance,anti-friction,thermostability and anti-oxydic.such as stainless steel,acid-resistant steel,heat-resistant steel,spring steel,tool steel and so on.

3. Chromite is used to produce Chrome brick,,Chrome-magnesium brick and other special refractories in fireproofing.

Specifications

1. Ferro chrome

1).Type;HC MC LC

2).Brand:FeCr67C6.0,FeCr55C600,etc

3).strict quality control

4).Factory price

2. High Carbon Ferro Chrome

Ferro Chrome

FeCr

1).ChemicalCompositions:Fe,Cr,C,Si,P,S

2).Type:High,Medium,low,MicroCarbon

3).FeCr67C6.0,FeCr55C600,etc

4).Improve antioxidation.

Packaging & Delivery

Packaging Detail: | 1MT/BAG |

Delivery Detail: | 15-30days |

- Q: CNC alloy milling cutter how to produce?What is the cutting edge of the machine tool?What is the surface coating?What is the cost of plating?Prawns talk about it in detail, I do alloy accessories, I would like to learn some processing methods ~ ~!

- CNC carbide cutter is used to hard alloy powder and powder metallurgy mould after sintering, the hard alloy blade (blank, can not be directly used), then after grinding the surface and edge (this can be installed on the cutter head, and also can be used) in coating the surface to improve its wear resistance, have finished milling blade.The blade is machined with a special blade grinder.

- Q: Where can I buy more than 94 hardness carbide cutter head, welding, the best address in detail, thank you!

- It's no problem to weld cemented carbide. Please call me when you need it

- Q: How to detect carbide material is raw material or recycled material, what is the difference?

- The original material has uniform particle size and stable performance. High priceGenerally, the size of recycled materials is poor, and the finished products are not stable. The price is relatively cheapIn general, carbide factories have specialized testing equipment

- Q: Is Zhuzhou the largest cemented carbide producer in Asia?

- Of course, yes, or how could the 601 factory be so famous? That's the old military enterprise. It's the hard tool factory now. I hope it can help you!

- Q: What is the hardness of cemented carbide?

- Different grades, different hardness, usually (86 ~ 93HRA, equivalent to 69 ~ 81HRC);

- Q: What kind of industry can use carbide?

- Coal, steel rolling, non-ferrous metal rolling, mechanical processing.

- Q: Several hard alloy cutter lathe with?

- YG car, pig iron and so on, YT, steel and the like, high temperature resistant, YW car alloy steel, the highest strength.

- Q: After welding, and then sharpening, grinding into 4 Pyramid shape, and then used to knock stone, which is not easy to bad, which is more durable? Model number is D224, I would like to ask you, which should I buy? I'm mainly used for knocking stones.

- YG8 is suitable for YG6 with higher hardness, but less impact toughness

- Q: K carbide carbide cutting tools, mainly used for turning what materials?

- Suitable for processing stainless steel, non-ferrous metals, non-metallic materials, cast iron and so on

- Q: My uncle is a hard alloy round bar. Can you tell me where to use an alloy round bar?

- I have some hard alloy round bars (tungsten steel) and high speed steel round rods (all used for cutting tools). Now I want wire cutting, laser, diamond, wire cutting

Send your message to us

LC LOW CARBON FERRO CHROME FECR ALLOYS MANUFACTURER SUPPLY

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords