Medium Carbon -Ferro-Manganese C1.5 CNBM Supplier

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Medium Carbon -Ferro-Manganese C1.5 CNBM Supplier

Usage of Ferro manganese

1. Mainly used as alloy additives and deoxidizer in steelmaking.

2. Used as alloy agent ,widely applied to be widely applied to alloy steel, such as structural steel, tool steel, stainless and

heat-resistant steel and abrasion-resistant steel.

3. It also has the performance that it can desulfurize and decrease the harmfulness of sulfur. So when we make steel and cast iron, we always need certain account of manganese.

Introduction of Ferro manganese

Silicon Manganese is produced depending on the resources available, either from silicious manganese ores or from manganese rich slags that are a by-product of Ferro Manganese production. It is used in its own right as an additive in the steel industry as a deoxidant or utilized in the production of other manganese alloys.

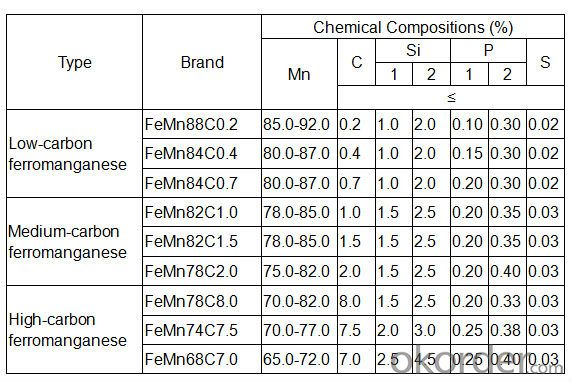

Specification of Ferro manganese

The specification and size can be made as your demand.

Pictures of Ferro manganese

- Q: What's the use of recycling cemented carbide?

- In the cutting tool is also hard alloy materials, recycling can be re - cemented carbide cutting tools ah.

- Q: How much does carbide WC contain?

- For example, YT15, which represents average TiC=15%, is tungsten carbide cobalt carbide with the remainder of tungsten carbide and cobalt contentTungsten, titanium, tantalum (niobium) carbidesIs the main component of tungsten carbide, titanium carbide, tantalum carbide (or niobium carbide) and cobalt. The hard alloy and hard alloy general or universal hard alloy.

- Q: the blade is hard alloy, the processing material is QT600, the plane lower tool margin is 4mm, the speed and the knife

- This belongs to the category of ductile iron, more difficult to process, because the material is hard particles, it is recommended around S=1200 F=400

- Q: Have seen many of the whole alloy cutting tool brand, I would like to ask, the global overall alloy cutting tool brand, which have quality and price advantage, I want to be a cheap brand regional agent!

- Brands have Swedish shandeweike, Israeli American Kenna; in accordance with Scafa, second tier brands are MITSUBISHI, Chinese Zhuzhou diamond brand, German Walter, three line brand in Taiwan, South Korea and China's Zigong Great Wall, Zhuzhou Jingcheng diamond card card, Qinghe etc. many, this is not the only one. In short, hard alloy cutter is very complex do you want to say, the light is not enough to know the brand, but also need to learn a lot of tools and machining knowledge of it. Finally, I wish you success!

- Q: What are the differences in performance between cemented carbide cutting tools and PCD cutters (polycrystalline diamond)?

- PCD has a very high hardness, but its toughness is not as good as carbide, much lower than high-speed steel, therefore, the main failure form of PCD cutting tool is cutting edge.PCD cutters can effectively process non-ferrous metal materials and non-metallic materials. Such as copper, tungsten and other non-ferrous metals and their alloys, ceramics, hard alloy, various fiber and particle reinforced composite materials, plastics, rubber, graphite, glass and wood, but the diamond is not suitable for cutting steel and other iron materials.

- Q: What are the main causes of wear of high speed steel cutting tools and carbide cutting tools?

- The tool wear mainly depends on the physical and mechanical properties and cutting conditions of cutting tools and materials. Under different conditions, tool wear has different characteristics. 1, hard point wear; 2, adhesive wear; 3, diffusion wear; 4, chemical wear;

- Q: Where does Tianjin sell yt30 carbide tool?

- Now there are the same, express, everything is not afraid. I am the agent of Zigong the Great Wall brand cemented carbide, quality assurance, definitely authentic.

- Q: What blade does the high carbide material use?

- No ceramic blade, with PCD, the wear resistance of the ceramic blade or worse, the car hard alloy finishing non diamond tool, we have tried before, the crude car available the whole CBN tool, we use the case of personal data, some contact, welcome to consult

- Q: How hard is the carbide knife?

- Seven or eight, Baidu is absolutely no problem.

- Q: Where can I use cemented carbide?

- Cemented carbide is a kind of alloy material made by powder metallurgy process of hard metal and bonding metal of refractory metal.Hard alloy with high hardness, strength and toughness, good wear resistance, heat resistance, corrosion resistance and a series of excellent performance, especially high hardness and wear resistance of it, even at a temperature of 500 DEG C also remained unchanged, at 1000 degrees C still have high hardness.Hard alloy is widely used as a tool material, such as turning, milling, planing, drilling, boring, used for cutting cast iron, non-ferrous metals, plastics, chemical fiber, graphite, glass, stone and steel, can also be used for cutting steel, stainless steel, high manganese steel, tool steel and other hard processing materials. Can be used to make drilling tools, mining tools, drilling tools, measurement tools, wear parts, metal grinder, cylinder liner, precision bearings, nozzle, metal mold (such as wire drawing dies, molds, mold, nut bolt fasteners and various molds, carbide goodnature can gradually replace the steel mold before).Carbide mainly YT, YN, YW and YG series, according to the different properties applied to different fields.

Send your message to us

Medium Carbon -Ferro-Manganese C1.5 CNBM Supplier

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords