HIGH CARBON FERRO CHROME FECR ALLOYS MANUFACTURER SUPPLY CIQ APPROVAL

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ferro Chrome

Chrome is always used to improve the antioxidation and corrosion resistance of steel to make the surface of steel after it is oxidized to form strong adhension oxide film. Then it stops being oxidized or decelerates being oxidized.Micro-Carbon ferro chorme is applied to making stainless, acid-resistant steel and heat resistant steel.

Chrome is mainly used to improve the antioxidation and corrosion resistance of steel to make the surface of steel after it is oxidized to form strong adhension oxide film. Then it stops being oxidized or decelerates being oxidized. Micro-carbon ferro chrome is applied to making stainless steel, acid-resistant steel and heat resistant steel.

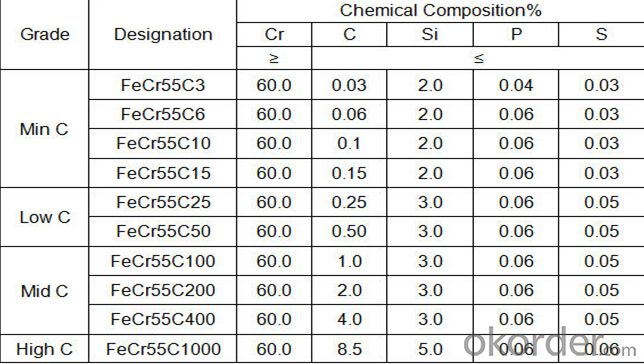

Specifications

High Carbon Ferro Chrome

1. Original manufacturer

2. The stability of the shipments

3. Free samples

4. Relatively lower cost

Products information

1. It can be used to produce FerroChrome and Chrome metal in metallurgy industrial.

2. As a kind of steel addition,it is used to produce various special steels with high strength,corrosion resistance,anti-friction,thermostability and anti-oxydic.such as stainless steel,acid-resistant steel,heat-resistant steel,spring steel,tool steel and so on.

3. Chromite is used to produce Chrome brick,,Chrome-magnesium brick and other special refractories in fireproofing.

Specifications

1. Ferro chrome

1).Type;HC MC LC

2).Brand:FeCr67C6.0,FeCr55C600,etc

3).strict quality control

4).Factory price

2. High Carbon Ferro Chrome

Ferro Chrome

FeCr

1).ChemicalCompositions:Fe,Cr,C,Si,P,S

2).Type:High,Medium,low,MicroCarbon

3).FeCr67C6.0,FeCr55C600,etc

4).Improve antioxidation.

Packaging & Delivery

Packaging Detail: | 1MT/BAG |

Delivery Detail: | 15-30days |

- Q: suitable for processing the whole alloy drilling, milling, reaming and other cutting tools. This alloy tungsten, cobalt content, how many of you?

- Just found the carbide under YK15, its cobalt content in 10%.According to its brand, YK15 should be used to process cast iron, so the main ingredient should be WC+Co.So its WC component should be in 89-90% (just for inference, for reference only)Based on the molar mass of WC, the mass fraction of the W content is deduced

- Q: I only know a few big, like Zhuzhou, Chun Bao, Xiamen tungsten diamond. Anything else? I'm looking for a tool cutter

- What kind of cutting tools do you have? I can give you some information first

- Q: What is called cemented carbide?

- Hard alloy with high hardness, strength and toughness, good wear resistance, heat resistance, corrosion resistance and a series of excellent performance, especially high hardness and wear resistance of it, even at a temperature of 500 DEG C also remained unchanged, at 1000 degrees C still have high hardness. Hard alloy are widely used as tool materials. Such as turning, milling, planing, drilling, boring, used for cutting cast iron, non-ferrous metals, plastics, chemical fiber, graphite, glass, stone and steel, can also be used for cutting steel, stainless steel, high manganese steel, tool steel and other hard processing materials. Hundreds of times now cutting speed of new carbide tool is carbon steel.Carbide can also be used to make rock drilling tools, mining tools, drilling tools, measuring tools, wear-resistant parts, metal abrasives, cylinder liner, precision bearings, nozzles and so onIn the past twenty years, coated carbide also come out in Sweden.1969 in the successful development of titanium carbide coated tools, the tool is a matrix of tungsten carbide titanium carbide cobalt alloy or cobalt tungsten carbide, titanium carbide surface coating thickness of only a few microns, but with the same grade alloy tool compared to prolong the service life of 3 times, cutting to increase the speed of 25% ~ 50%.20 in 70s has been fourth generation coating tools, can be used for cutting hard processing materials.

- Q: Big brother on the 1 floor is exaggerating. It's impossible at all

- If the precision of the thread is not high enough, it can be produced by pressing.

- Q: Is there any pollution in the production of cemented carbide?

- There is no pollution, the most basic production, carbon dioxide, sulphur dioxide after heating, heavy water generated after, there are also the noise, dust, harmful substances should be there on the edge of it, so do the work people must take the mask ah, ordinary mask should be useless the kind of good filtration mask, good sealing performance should be divided into ordinary medical masks, and senior two. Ordinary medical masks cost is not high, protection is not outstanding; and senior medical masks is surgery the doctor or dentist, pay attention to the fluid barrier, filtration of particles, guarantee in precision work environment with permeability, haze and mean gray dust, haze (Yan Xia) in the air of sulfuric acid, nitric acid and other disorders that cause visual history of haze. The difference between haze and fog is that when the haze occurs, the relative humidity is not large, while the relative humidity in the fog is saturated. (if there is a large amount of condensation, the relative humidity may not reach 100%, it may appear saturated). Sources of toxic particulate matter in cities: first of all, automobile exhaust. Diesel vehicles are the highest standard American imports of medical masks, such as Beijing work guard Xin, filter good, not only anti particles, but also anti droplets.

- Q: What is steel bonded carbide? What are its characteristics?

- Steel bonded hard alloy is a kind of material between steel and hard alloy, has the following characteristics: good technological properties with processing and heat treatment, under the annealed state, can be used in machining, car equipment and tool milling, planing, milling, drilling and other mechanical processing. Also, forging welding. Compared with hard alloy, low cost, wide application range.

- Q: Carbide coated drill bit. Do you have one there?

- 5., the drill can be re coated after grinding, pre treatment should be done before coating. To increase the coating effect.

- Q: What type of carbide is the most ductile?

- Cemented carbide material with tungsten and cobalt carbide toughness is better, at present the carbide grade in the most toughness of YG15. The relation between cobalt content and toughness is shown below. It can be seen that cobalt content and 13%-16% toughness are the best. In this interval, only YG15 cobalt content is 15%.

- Q: After welding, and then sharpening, grinding into 4 Pyramid shape, and then used to knock stone, which is not easy to bad, which is more durable? Model number is D224, I would like to ask you, which should I buy? I'm mainly used for knocking stones.

- YG8 is suitable for YG6 with higher hardness, but less impact toughness

- Q: What are the types and types of carbide inserts?

- According to the size of the grain, it can be divided into ordinary cemented carbide, fine grain cemented carbide, sub fine and ultra-fine grain cemented carbide, and newly introduced twin cemented carbide. Model manufacturers are different, different models.Carbide inserts are made of hard alloy, an alloy made from refractory metals, hard compounds, and bonded metals by powder metallurgy.

Send your message to us

HIGH CARBON FERRO CHROME FECR ALLOYS MANUFACTURER SUPPLY CIQ APPROVAL

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords