large roof wall color steel composite and modified phenolic fireproofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

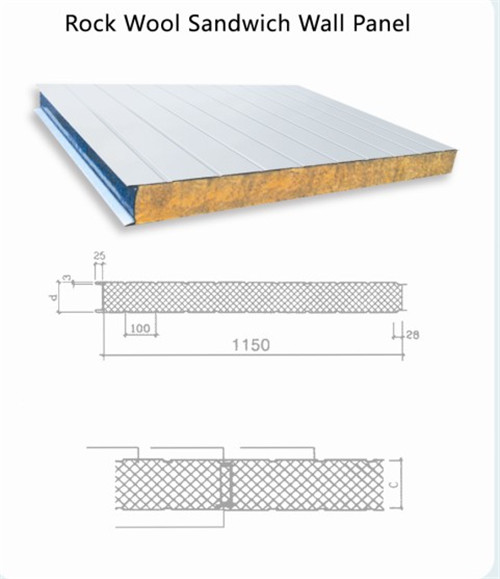

| Place of Origin: | Hebei China (Mainland) | Brand Name: | wzh | Model Number: | 950/1150mm for wall or ceiling or 950mm as roof |

| Panel Material: | Metal | Type: | Rock Wool Sandwich Panels | Thickness: | 50/75/100/125/150/200 mm |

| Color: | Many color are available, but white grey, sea blue and bright red | Materials: | Rockwool, EPS, PU sandwich and two sides are oosteel sheet | Certification: | ISO9001&ISO14001 |

| Name: | sandwich panel; coposite panel;steel plastic composite pannel | Length: | as your require | Effective width: | 950/1150mm for wall or ceiling or 950mm as roof |

| Utilisation: | prefabricated house, container house,cold room | Kinds: | roof panels; wall panels | Charastic: | heat perservation; waterproof |

Packaging & Delivery

| Packaging Detail: | standard export pallet,with protective corner guard and film on the four sides |

| Delivery Detail: | 15 days after recieved despoit |

Specifications

EPS composite board rockwood composite board glassfiber composite board

Light weight

High intensity Sound proof Easy installat

EPS composite board rockwood composite board glassfiber composite board

The usual sandwich panels include rock wool Sandwich panel, EPS sandwich panels, PU Sandwich Panel, glass fiber sandwich pannels. The up & down surface of this panel is Galvanized & Prepainted steel sheets, core material is rock rood, EPS, PU, and glass fiber. It is formed by heating, foaming & laminating. It is the best material for temperature keeping and sound insulation. It is widely used as the wall or roof for cold storage, industrial workshop, public building etc.

Specifications

(1)Core Material: Rock Wool, EPS, PU; Surface Materials: Galvanized Steel sheets or Prepainted Steel sheets.

(2)Wall Thickness: 40, 50, 60, 80,100,120,150,180,200,250mm

(3)Max. Width: 1200mm

(4)Length: according to client's demands, engineering requirements and shipment conditions

(5) Application: for ceiling & wall, partition wall

(6) Widely used in common steel structure and storey adding projects,e.g. adding storey to small steel structure industrid factory building worehouse,suburbon temporary office,residentid quarters,school,hospital,etc.

Characteristics

1) With a light weight, a giraffe fitting and random incise characteristic, the fitting is much simpler, and it can advance the benefit and save the time limit for a project

2) Color coated sandwich panel's surface material and heat preservation material are non-burn or hard-burn materials, entirely satisfy the fireproofing criterion request

3) Manifold disquisition and oversea used approving more than 40 years. By especial coated dispose, the color coated steel panel's guaranty is 10-15 years, and the panel's life express 35 years by painting the antisepsis material after each 10 years

4) Pressing steel panel with the clear line, and many colors for choice, and suit with any different building style materials, achieving the satisfying effects.

5) In common use heat preservation materials are rock-wool, polystyrene,

polyurethane, all with lower thermal conductivity and favorable heat preservation and heat insulation effects

6) Sound insulation intension can be 40-50dB, it is the most effective sound insulation material

7) Pressing steel panel can be arbitrariness incise, it can satisty the especially design demands

8) Use the high strength steel panel for the base metal (contradict open and pull intension 5,600kg/cm2), adding the most advanced design and roll pressing moulding, it gets the best structure character

9) Improves speediness and springiness designs according to clients' requirements.

- Q: What are the characteristics of KRD blue epoxy sheet?

- "KRD blue epoxy plate" in 1938 by the German company in Switzerland patent application in Switzerland, 1946 secretly put into operation in the high-end military plate, in 2008 Germany Kerui De company in the original epoxy board formula based on improved by adding KRD blue Water resistant weather factor, to produce high-end "KRD blue epoxy plate", put the German market, mainly used in luxury cruise ships and high-end cars and high-end interior furniture production. October 2009 European style (Hong Kong) bathroom International Development Co., Ltd. formally introduced "KRD blue epoxy plate" production line into the civilian bathroom furniture production. ????"KRD blue epoxy sheet" has a strong chemical resistance and water resistance. In the curing system of ether, benzene ring and fatty hydroxyl is not susceptible to acid and alkali erosion. Can be used for two years in seawater, petroleum, kerosene, 10% H2SO4, 10% HCl, 10% HAc, 10% NH3, 10% H3PO4 and 30% Na2CO3, and half a year at 50% H2SO4 and 10% HNO3; % NaOH (100 ° C) for a month or soaked in fresh water for 50 years, the performance remains the same. ????"KRD blue epoxy plate" molecular chain structure contains two or more epoxy groups of polymer compounds, process performance is good, strong nail holding force, product size and stability, no radiation, zero formaldehyde, is the current The forefront of the international environmental health, strong weather resistance of high-end furniture preferred plate. "KRD blue epoxy plate" Appearance features: A high density light B The appearance of the plate is light blue C strong flexibility

- Q: Jin Liyuan plate quality how

- My home is Jinliyuan plate, the quality is not bad, the measured quality has reached the national standard

- Q: What is the board made of wood chips

- According to the composition of wood chips, MDF or particleboard. These boards are generally used to do wardrobe backplane, where hardness is not demanding. Foshan, Jisheng Osaka. There are several years of custom design experience wardrobe.

- Q: China 's top ten brands of decorative plates

- The specific ranking is not clear, I know we are here to buy more of the king coconut plate, bunny plate and the new millennium plate.

- Q: What is the HS code of the PVC sheet?

- 39202017.00 PVC board 39204300.90 recycled PVC board 39204300.90 PVC board 39204300.90 color PVC board 39204300.90 color printing PVC board 39204300.90 PVC PVC board 39204900.90 anti-static PVC board 39219090.00 color PVC board 39261000.00 PVC board clip 39269090.00 PVC board display stand

- Q: First, the backplane is generally 9MM, the door is generally 15MM, the cabinet is generally 18MM, the reasons are as follows, the cabinet is shaped, basically rarely move it, 9 thick wall, without any strength, cost Reduce the door to do the paint, both sides of the panel also add up to 15 +3 * 2 = 21, do not say, the general plate can not do paint, must be decorated panels, and drawers with nine thick floor , Taking into account the drawer space and weight problems, the use of convenience, as well as the aesthetic degree, so that, so that the cost is reduced, without affecting the use, and beautiful, if it is a board furniture finished cabinet, may use 18MM , Taking into account its stability

- First, the backplane is generally 9MM, the door is generally 15MM, the cabinet is generally 18MM, the reasons are as follows, the cabinet is shaped, basically rarely move it, 9 thick wall, without any strength, cost Reduce the door to do the paint, both sides of the panel also add up to 15 +3 * 2 = 21, do not say, the general plate can not do paint, must be decorated panels, and drawers with nine thick floor , Taking into account the drawer space and weight problems, the use of convenience, as well as the aesthetic degree, so that, so that the cost is reduced, without affecting the use, and beautiful, if it is a board furniture finished cabinet, may use 18MM , Taking into account its stability

- Q: PCB is used to do the PCB, but the middle of the PP material is dicyandiamide, black

- Refers to the surface is FR4 light green, the middle of the black plate

- Q: How much profit margins of decoration materials

- Tiles profit is relatively large, see what you take the route, the brand profit the largest, the smallest profit transfer, wood floor is the same

Send your message to us

large roof wall color steel composite and modified phenolic fireproofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords