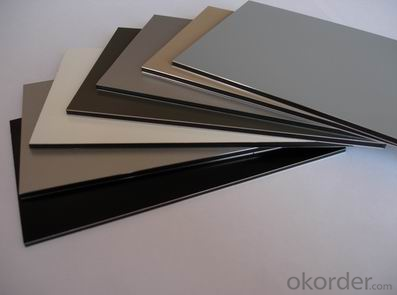

ALUMINUM PE COMPOSITE PANEL DIFFERENT COLORS

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Breif details

Place of Origin: Zhejiang, China (Mainland)

Brand Name: Jinxiang

Model Number: JX 6001

Usage: Outdoor

Function: Anti-Static, Antibacterial, Fireproof

Surface Treatment: Anodized, Brushed, Foil Decoration, Mirror, PE Coated, Printing, PVDF Coated, Nano Coated

Panel thickness: 2mm/3mm/4mm/5mm/6mm

Aluminum thickness: 0.10mm/0.12mm/0.15mm/0.21mm/0.30mm/0.40mm/0.50mm

Width: 1220mm,1250mm,1500mm,1570mm

Coating: PE, PVDF,NANO

Color: over 300 kinds of color (as per customer's requirement)

Core: Breakable,Unbreakable,Fireproof

Length: 2440mm (according to customers' request)

Standard size: 1220x2440mm

Logo: OEM (customer's logo and brand are welcome)

Name: Aluminium Composite Panel

2. Main Feature

. Excellent fireproof characteristics

Super peeling strength

Perfect cold resistance performance

Excellent surface flatness and smoothness

Superior weather, corrosion, pollutant resistance

Even coating, various colors

Superior impact resistance

Lightweight, easy to process and installation

Easy to maintain

3.Main Specification

PE/PVDF coated Aluminium Composite Panel Specification:

| Width(mm) | 1220 | 1250 | 1500 | |||||

| Length(mm) | 2440 | Or according to customer's request | ||||||

| Panel thickness(mm) | 2 | 3 | 4 | 5 | 6 | |||

| Aluminum thickness(mm) | 0.10 | 0.12 | 0.15 | 0.18 | 0.21 | 0.3 | 0.4 | 0.5 |

| Coating | PVDF | PE | Brush | Mirror | Glossy | Wood and stone texture | ||

4.FAQ

What is the main use for aluminium composite panel?

1) Gas piping, cables, building materials, etc (this product fills a gap

in the domestic construction materials field, with performance

indexes superior to panels manufactured overseas)

2) Curtain wall decoration for buildings where security is important,

such as airports, hospitals and research centers

3) Curtain wallboards for outside walls of normal buildings

5.

- Q: My family bought a cupboard made of melamine board these, a week or after the taste? These taste has no harm? Is there a methanol? Is it good to use these furniture?

- Melamine board, also known as double decorative panels, paint panels, ecological board, it was called a molding board. Its substrate is also particleboard and MDF, made by the substrate and the surface bonding, the surface veneer mainly domestic and imported two categories, because it is after the fire, anti-wear, waterproof soaking treatment, the use of results Similar to the composite wood flooring. Melamine decorative board performance: 1, can be any imitation of a variety of patterns, bright color, for a variety of wood-based panels and wood veneer, hardness, wear resistance, good heat resistance. 2, chemical resistance in general, can resist the general acid, alkali, grease and alcohol and other solvent wear. 3, the surface smooth and smooth, easy to maintain cleaning. Melamine board with natural wood can not both the excellent performance, it is often used for indoor construction and a variety of furniture, cabinets on the decoration. Melamine board is a wall decoration material. Some people use melamine board counterfeit flooring for floor decoration, which is not appropriate. Common specifications: 2440mm × 1220mm, thickness 1.5-1.8Cm.

- Q: Density board and Orson board difference

- MDF is made of wood and wood is not pressed by the degree of high temperature density is not Austrian loose board density

- Q: How to go to the market to pick a good plate?

- 1, the choice of woodworking board is particularly important. It is recommended to buy Glulam, because the laminate is solid wood, no outer skin, not easy to make fake. If you use blockboard, choose the big manufacturers, such as Langfang Jinqiu, Zhejiang Moganshan, the board was above the manufacturer's security check phone. And each board has its only serial number, like a person's identity card, can not do the fake! 2. Australian pine board is now mostly domestic, but little impact on the quality of decoration, as long as the quasi-price, it will not be too fooled. 3. The choice of the first panel depends on the color texture of the veneer, the natural veneer has a slight color difference, the artificial veneer texture is very consistent, but looks fake; followed by the bottom plate material, Liu An core floor is now very little, the panel snapped inside the folder wire. Poplar core prone to primer dialysis, a long time the surface of the paint pollution. Zamu core of the basic quality can be, and economic and durable. In fact, it is easy to say, but the layman is difficult to see inside the essence, it is best to ask a professional friend to help choose.

- Q: What is love board?

- AIG is the Austrian Group of Agrites FRITZ EGGER GMBH Co. is located in 17 factories in Europe, the production of man-made sheet, environmental protection level to the European E1 level. The Aige plate substrate is covered with a layer of special dipping treatment, with anti-characterization, acid and alkali surface, is widely used in plate furniture and kitchen furniture, English referred to as MFC. ??????? The love plate is selected from coniferous trees grown in the continental margin of the European continent. The love grid overcomes the shortcomings of natural wood and has physical properties that are not easily deformed and stable. Ai grid is a kind of natural logs by cutting, crushing, high temperature and pressure made of a more suitable for furniture production and use of the plate.

- Q: What is the board made of wood chips

- According to the composition of wood chips, MDF or particleboard. These boards are generally used to do wardrobe backplane, where hardness is not demanding. Foshan, Jisheng Osaka. There are several years of custom design experience wardrobe.

- Q: Now on the market E0 grade plate how? Now on the market E0 grade plate how?

- According to the European environmental standards, the wood products in accordance with the release of formaldehyde content, divided into three levels, namely E0 level (formaldehyde emission ≤ 0.5mg / L), E1 level (formaldehyde release 0.5mg / I ~ 1.5mg / L), E2 level (formaldehyde emission greater than 1.5mg / L). Only to obtain E1-certified wood products can be used for interior decoration, known as green building materials, absolutely no harm to the human body, E0-class plate is the highest environmental standards of wood-based panels, suitable for children, pregnant women and other resistance Low room decoration of the crowd. E0 grade sheet, refers to the international top environmental standards, formaldehyde emission ≤ 0.5mg / L medium density fiberboard, high density fiberboard, particleboard, oriented particleboard and other furniture can be used for furniture and home improvement wood products, E0, E1, E2 is the detection standard of formaldehyde emission.

- Q: 601 grades of stainless steel, would like to know its chemical composition and use, thank you!

- NAS 601 60Ni-23Cr-1AI-0.2Ti Mainly used for gas turbine parts, heat treatment furnace parts.

- Q: What is the difference between A-board and B-board?

- Class A grade B refers to the quality of the wood (density, formaldehyde content, etc.) grade. According to the corresponding standard, according to the wood of the knots, decay, insects, cracks and blunt edges (if the logs are no such defects), bending, twill (or twist) and other defects of varying degrees. The quality of the wood (density, formaldehyde content, etc.) as a class A, B and other different grades

- Q: What is the difference between acrylic and resin plates?

- Acrylic from English, the chemical name is abbreviated as: PMMA; PMMA, also known as polymethyl methacrylate, is made from acrylic monomer (pellet or liquid) MMA polymerization. Because the transparency is very high, can be as high as 93%, so it is also known as: plexiglass. Acrylic is not plastic, because the plastic is PVC collectively, from the use of acrylic terms: can be divided into: advertising materials, decorative materials, crafts materials. Resin board, also known as eco-resin plate (Ai Hao), chemical name: PETG PETG is a non-crystalline copolyester, PETG commonly used comonomer is 1,4-cyclohexanedimethanol (CHDM), all known as polyethylene terephthalate-1,4-cyclohexane Dimethanol ester. It is the product of polycondensation of terephthalic acid (TPA), ethylene glycol (EG) and 1,4-cyclohexanedimethanol (CHDM) by transesterification. Compared with PET, -cyclohexanedimethanol comonomer, with the PCT more than ethylene glycol comonomer, therefore, PETG performance and PET, PCT is very different. PETG sheet has outstanding toughness and high impact strength, the impact strength is modified polyacrylate 3 to 10 times, and has a wide processing range, high mechanical strength and excellent flexibility, compared to PVC transparency High, glossy, easy to print and have an environmental advantage.

Send your message to us

ALUMINUM PE COMPOSITE PANEL DIFFERENT COLORS

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords