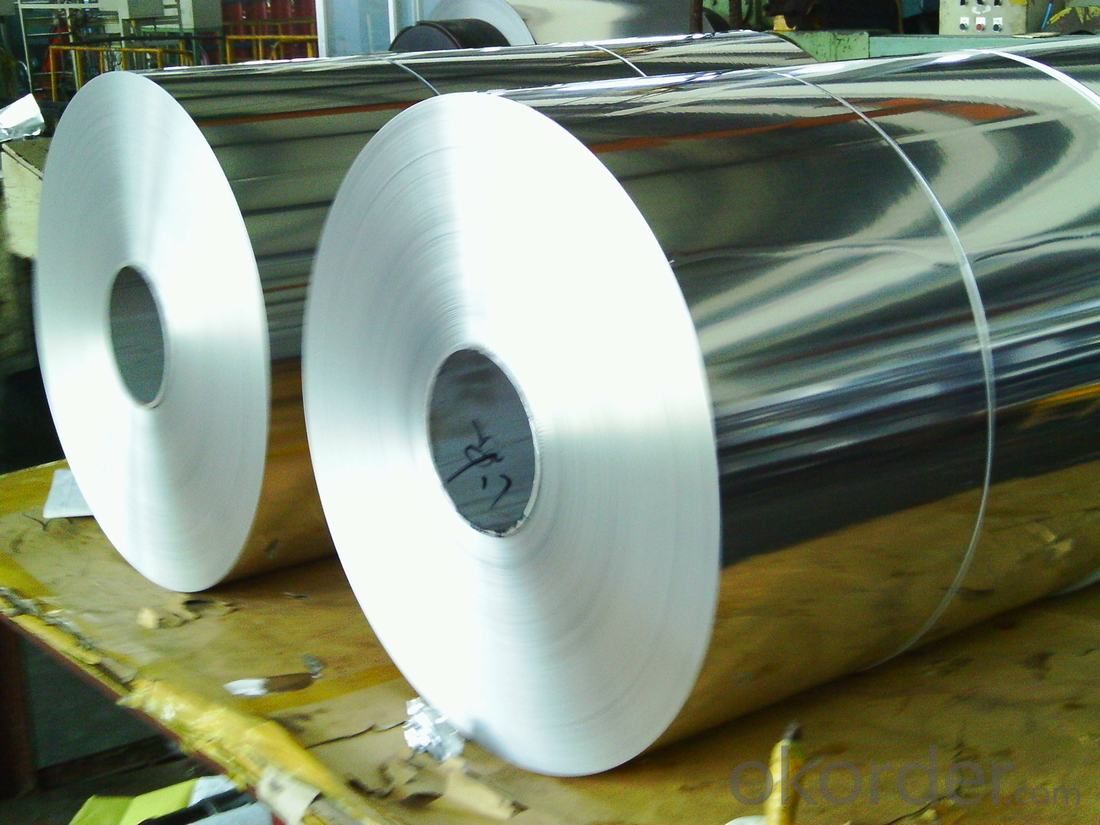

Large Aluminum Sheets for Sale - Smooth Edge 1050/1100/1200/1070 Aluminum Strips/Belt for Gutter

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 600 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminum Description

-Hot rolling 1100/1050/1020/1060 aluminum coils for roof sheet is used for celling, decorate, ACP,Curtain Wall,Roofing Sheet, PC base, radiator,cookware,deep drawing and more.

- 1 series Aluminum Coils temper: O-H112

-1 Series Aluminum Coils Alloy: 1100/1050/1060/1200/1035/1070

-Thickness: 0.5-10mm

-Width:200-1500mm

-Length:12m Max.

Temper: h14,h16,h18,h22,h24,h26,h32,o/f

Thickness: o.o3mm-3.0mm

Width: 30mm-1700mm

Coating: pe(polyester),pvdf,epoxy

Painting thickness: standard 16-25 mic, max 40 mic

Color: according to ral colors or customer's samples

Packaging & Delivery

| Packaging Details: | Coil ID :508MM Coil Weight : about 2.5 tons or as per customers requirement Packing ; In Export Sea worhty wooden pallets Eye to wall or Eye to Sky One container can be loaded about 20 mts |

| Delivery Detail: | within 25 days after receiving L/C deposit |

- Q: Can aluminum sheet be used for electrical grounding applications?

- Yes, aluminum sheet can be used for electrical grounding applications. Aluminum is a good conductor of electricity and is commonly used in electrical grounding systems due to its low resistance and cost-effectiveness.

- Q: When zinc dust and sulfur dust are combined in certain proportional ratios and ignited, a violent exothermic reaction occurs. Because the reaction only depends on two components; zinc and sulfur, but not oxygen, the reaction has all of the components that it needs within the mixture. The same is also true for a mixture of magnesium and sulfur.However, the same reaction does not occur with iron and sulfur. Instead, the mixture reacts slowly over a period of a few minutes rather than flashing to smoke in less than a second. Now for my questions:1: If aluminum and sulfur were combined in the same proportional ratios as the zinc and the magnesium mixtures were, would the reaction be as fast as the zinc and the magnesium mixtures? Why or why not?2: What properties of the different metals used in these mixtures makes them behave so differently?

- the forged iron crucible will honestly be dragging the warmth away,so attempt to discover a ceramic crucible---you will possibly have the potential to discover them at any rings furnish domicile.you will additionally so discover commercially arranged fluxes for melting,if no longer Borax powder is a fluxing agent I generally use.With the small quantity of meral you're wishing to soften,i think of your MAPP torch ought to artwork,be confident to change the flame to a lowering flame to steer clear of gassing the metallic.the availability domicile RIOGRANDE has an entire inventory of something you are able to require besides as some preprepared alloys which you will choose to objective.

- Q: What specific criteria or conditions must be met when utilizing high-quality aluminum sheets in construction?

- <p>High-quality aluminum sheets used in construction projects require adherence to specific standards. They must possess high strength, corrosion resistance, and durability to withstand environmental conditions. Compliance with industry standards such as ASTM or ISO is crucial. Additionally, the sheets should be compatible with other construction materials and meet safety regulations. Proper installation techniques and qualified personnel are also essential to ensure the integrity and longevity of the construction project.</p>

- Q: How do aluminum sheets perform in extreme weather conditions?

- Aluminum sheets are renowned for their exceptional performance in extreme weather conditions, as they possess inherent properties that render them highly resistant to corrosion and capable of enduring harsh environmental elements like rain, snow, and extreme temperature fluctuations. When confronted with hot weather, aluminum sheets possess the ability to reflect sunlight and dispel heat, thereby averting any warping or deformation. This characteristic renders them suitable for utilization in regions characterized by high temperatures or direct exposure to sunlight. Similarly, in cold weather, aluminum sheets retain their strength and do not become brittle, making them dependable in freezing temperatures or regions prone to heavy snowfall. With a low coefficient of thermal expansion, they can withstand contraction and expansion without any detrimental effects such as cracking or damage. Moreover, aluminum sheets exhibit excellent resistance to moisture, which safeguards them against rusting or corroding when exposed to rain or high levels of humidity. This quality makes them an ideal choice for employment in coastal areas or regions with substantial rainfall. Additionally, aluminum sheets possess the advantage of being lightweight yet durable, enabling them to withstand high winds and severe storms without compromising their structural integrity. This quality positions them as the preferred option for applications such as roofing, siding, and outdoor signage in areas susceptible to hurricanes or strong winds. All in all, aluminum sheets display remarkable performance in extreme weather conditions, which establishes them as a reliable and versatile material for various outdoor applications.

- Q: What is the maximum temperature aluminum sheets can withstand?

- The maximum temperature that aluminum sheets can withstand varies depending on the specific grade of aluminum. However, most aluminum alloys have a melting point ranging from 600 to 660 degrees Celsius (1112 to 1220 degrees Fahrenheit).

- Q: How do aluminum sheets perform in terms of formability?

- Aluminum sheets possess remarkable formability, renowned for their capability to be effortlessly molded and contoured into intricate configurations without encountering any cracks or fractures. The exceptional ductility and malleability of aluminum enable its transformation into diverse shapes, curves, and angles with relative simplicity. This inherent formability renders aluminum sheets highly adaptable for utilization in an array of applications, including automotive body panels, aircraft components, and architectural structures. Moreover, aluminum sheets exhibit commendable resistance to corrosion, further augmenting their performance in various environmental conditions. All in all, aluminum sheets amalgamate formability, strength, and durability, rendering them a favored choice across numerous industries.

- Q: When water continually sprays on the aluminum sheet, how to avoid corrosion of aluminum sheet and keep its water resistance?

- aluminum will react with oxygen, generating dense Al2O3 oxide film on the surface, once the pure aluminum is exposed in air, it will react with air, generating oxide film to protect it.

- Q: Can aluminum sheets be etched or engraved?

- Yes, aluminum sheets can be etched or engraved. Etching or engraving on aluminum sheets is a process that involves removing some of the material from the surface using acid or a high-powered laser. This can be done to create intricate designs, patterns, or even text on the aluminum sheet. The etching or engraving process can be used for various applications, such as signage, decorative pieces, or industrial parts. The resulting etched or engraved design on the aluminum sheet can be further enhanced by adding color or other finishes to create a desired look.

- Q: Are aluminum sheets suitable for use as materials for windows and doors?

- <p>Yes, aluminum sheets can be used for windows and doors. They are known for their durability, low maintenance, and resistance to corrosion and weathering. Aluminum windows and doors are energy-efficient, lightweight, and offer excellent security. They can also be easily customized in terms of size and design, and are often used in modern architecture for both residential and commercial buildings.</p>

- Q: I am looking to purchase a pressure cooker and the size that i want comes in aluminum while alot of the others are made from stainless steel. I am wondering if the metal makes a difference in the funtionality and if one doesn't stand up as well as the other.

- I have a large aluminum pressure cooker that I have owned and used often for over 25 years. It's never given me a bit of trouble. I do not cook really acidic things in it (which is what will cause pitting of the aluminum). If the largest size is the one in aluminum, I think it may be possible that it's not in stainless steel because of the weight issue. The aluminum pot and lid are quite heavy even when empty, and when they are full of food, it's difficult to move the full pot. The instructions for mine said to move the pot from the stove-top to a sink of cold water to reduce pressure instantly. So mostly, I don't carry the pot when full; I leave it on the stove-top and simply remove the pressure-weight (the jiggler) while wearing a oven mitt, when I need to reduce the pressure instantly. Hope this helps.

Send your message to us

Large Aluminum Sheets for Sale - Smooth Edge 1050/1100/1200/1070 Aluminum Strips/Belt for Gutter

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 600 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords