KXT (F) Fly Ash (slag) Dosing and Control System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

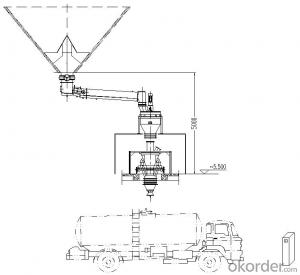

The KXT(F) achieve evenly and steadily dosing and accurately measurement for fly ash, and adapt for fly ash mass-flow measurement. The system is operating in 0.5-100t/h production line, receiving favourable reviews by users.

We can provide two form system base on different flow rate. For the flow rate of 0.5-30t/h system is consisted by flow-stability pre-feeder, flow meter and control system. For the flow rate of 15-150t/h system is consisted by special feeder valve, flow rate adjusting valve, weight adjusting valve and control system. The system is adapt for cement grinding station and cement milling system.

1. Composing of the KXT(F) system

The KXT(F) system is composed by flow-stability pre-feeder, KL flow meter and control device. The flow-stabilizing pre-feeder is installed under the fly ash silo, which supply steady flow fly ash. The fly ash enter into KXT meter through flow-stabilizing pre-feeder, the control device base on the flow rate feed back to the flow-stabilizing pre-feeder to adjust the rotating speed.

2. Flow-stabilizing pre-feeder device

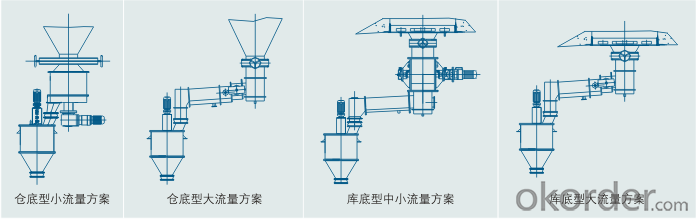

Flow-stabilizing pre-feeder device adopt different assembly mode base on the fly ash usage amount(t/h), storage and layout on-site. There are two basic programs to choose.

Program 1

Adopting WD flow-stabilizing pre-feeder as feeding device, with KL flow meter constitute a closed loop control. This program is usually used in small-flow fly ash measurement, measurement range is not more than 30t/h.

Program 2

The flow-stabilizing pre-feeder device made up of NXF rotary valve, pneumatic switch valve, electric flow valve and aerate separate case, with KL flow meter constitute a dosed loop control. This program is usually used in mass-flow fly ash measurement, measurement range is up to 150t/h.

3. Technical Index

Suitable material: fly ash, slag

Measuring accuracy: better than ±0.5%

Control accuracy: better than ±1.0%

Measuring range: 0.5~150t/h

environmental temperature: -20℃~60℃

relative humidity: ≤95%

Moisture of material: ≤ 2.5%

4. Specification | ||||||||

Model | KXT(F)-Ⅰ | KXT(F)-Ⅱ | KXT(F)-Ⅲ | KXT(F)-Ⅳ | KXT(F)-Ⅴ | KXT(F)-Ⅵ | KXT(F)-Ⅶ | |

Range (t/h) | 0.6~6 | 1.5~15 | 3~30 | 5~50 | 7~70 | 10~100 | 15~150 | |

Flow meter model | KL(F)-Ⅰ | KL(F)-Ⅱ | KL(F)-Ⅲ | KL(F)-Ⅳ | KL(F)-Ⅴ | KL(F)-Ⅵ | KL(F)-Ⅶ | |

Control cabinet | KXT-Ⅰ | KXT-Ⅱ | KXT-Ⅲ | KXT-Ⅳ | KXT-Ⅴ | KXT-Ⅵ | KXT-Ⅶ | |

The KXT (F) Coriolis force dosing system is applied to dosing fly ash and pulverized slag, it is benefit for the reuse of industrial waste and it can also increase mill output, ensure product quality and gain economic benefits. The system is characterized with stable feeding, accurate dosing, quick adjustment, simple process flow, compact arrangement, low investment cost, and wide measuring range etc.

The KL (F) system is designed under the patent, of which the principle is different from the glide slot and rush board flow meter, agravic meter, rotor scale, and belt weigher. The principle of the KL (M) meter is the Coriolis dynamical principle, the material moved in the dosing plate under the Coriolis force, and the force can be equal to the flow of the material, so the flow can be showed as special value. The KL (F) cannot be disturbed by any vibration and pressure, and the zero point can be changed by any deposit and aggradations.

The KL (F) flow meter can be used for the process of the dosing of the powder material independently. In the cement industry, the meter can be used for the feeding of the powder coal, fly ash, and several powder materials, like the grinding and mix of the clinker and the compound material, and the dosing of the bulk cement.

The flow meter is widely applied to the convoying and dosing of powder and granular materials in the metallurgy, electrical power, chemical engineering, foodstuff, ports, medicine power, , non-metallic mineral etc.

- Q: What is the proof of working in mechanical design?

- Outline first Ⅲ part, is to the qualification examination examination form, time, attention, and the structure of test paper, test question distribution, topic topic quantity, and degree of difficulty of related regulations and instructions.

- Q: What is a forklift? Forklifts are special equipment

- Forklift truck is an industrial transport vehicle, which is a variety of wheeled transport vehicles for loading and unloading, stacking and short-range transportation. International standardization organization ISO/TC110 is called an industrial vehicle. Often used for the transportation of large items in storage, usually with a fuel engine or battery. It's a special equipment.

- Q: Talk about how to cut the cost of moving materials.

- I think the main thing is to choose a range of suitable devices. If the moving objects and routes are relatively fixed, the use of the manipulator can be more efficient. The cost is naturally reduced.

- Q: The material needs to be transported, it is easy to produce dust.

- In general can be used in coal chemical industry material, and can control the dust conveying equipment are: the tube chain conveyor, screw conveyor, continuous chain bucket conveyor, bucket elevator, belt conveyor belt cover, scraper conveyor, and pneumatic conveying system and so on. If there is a technical problem, we are willing to answer for you and invite you to visit the user!

- Q: The wear-resisting parts in the broken machine are mainly the direct contact with the material

- There are many different types of crusher and different performance. For example: the jaw is broken, the hammer is broken, the fight is broken, the cone is broken... It is. Wear-resisting material is different also, also need according to the material hardness, strength of the material that is broken, the choice is ok. Material: white iron, alloy white iron (high chromium cast iron), high manganese steel, alloy steel (high, medium, low carbon and alloy)... It is. Prices are different because of different materials. Otherwise "overqualified person" not to calculate, "small material big use" not only use not, also do not calculate.

- Q: The development of material handling

- Domestic market competition is the basic material handling machinery, high-end market is mainly composed of multinational companies, domestic key large enterprise also had some markets in some specific fields; The participants in the mid-market market include large enterprises in China and small and medium-sized enterprises with excellent manufacturing technology and high management level. Many of the small scale, poor technology, poor management, lack of product innovation of enterprise, product quality is not high, low added value, poor economic benefit, in the industry of low-end market, competition is intense. "Twelfth five-year" period to 2020, is China's national economy sustainable development strategy implement and promote the development of circular economy, take a new road to industrialization, the basis for building a resource-conserving and environment-friendly society an important period. Attaches great importance to the society and the enterprise logistics role, vigorously develop modern logistics industry, to promote the development of and promote industry, improve the quality and efficiency of economic operation, enhance the comprehensive national strength and the enterprise competitiveness, has the very vital significance. It is an effective means of carrier for all walks of life of the national economy, including the manufacturing of material handling equipment which supplies the large amount of equipment needed for the second and third industries. The rapid and steady development of the national economy, the informationization and industrialization of the basic industries, provide the best opportunities for the manufacturing industry of materials handling equipment.

- Q: Why should we emphasize unitization and standardization in material handling

- Reducing the degree of climate impact, ensuring normal work, accelerating the flow of goods and improving efficiency. 1) logistics base module The logistics base modulus is the minimum size of the standard size of the logistics system. In basic module size was determined, the size of the various specific standards, should be based on basic module size, select the integer times to the prescribed standards for size, foundation modulus size is determined, just a standard size in multiple choice, it can be used as a standard of other size.

- Q: The beneficial effect of material handling machinery

- Material handling machinery is serving the production, its design and type selection should be subject to the needs of the production process, new material handling machinery but also often leads to the change and improvement of the manufacturing process. For example, the emergence of bucket wheel stacker reclaimer, formed the bucket wheel stacker reclaimer for heart, belt conveyor for blood vessels, the electronic computer is the nerve center of automation of large bulk material handling system, which changes the ports, mines and the layout of the power plant and so on of the bulk yard; It can simplify the structure of the factory and reduce the cost of construction.

- Q: What is the carrying equipment of the container cargo

- Shockproof and vacuum packaging, equipment hoisting, lower layer, translation, adjustment level, container (container), import crane, forklift professional service.

- Q: There are three things to do when the material is stacked up and down

- Make fire prevention, moistureproof, upper light to put orderly easy to find.I hope my answer will help you

Send your message to us

KXT (F) Fly Ash (slag) Dosing and Control System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords