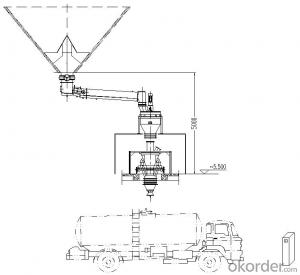

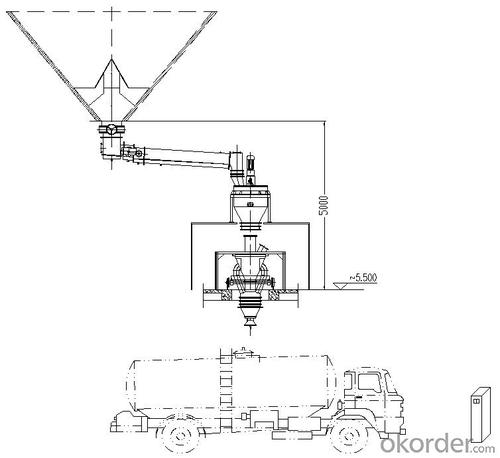

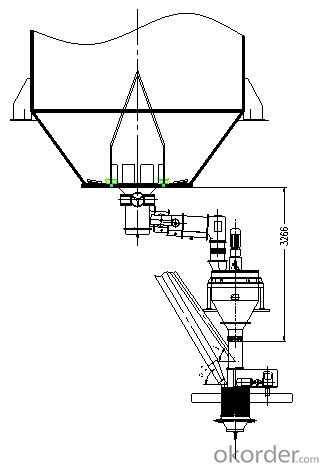

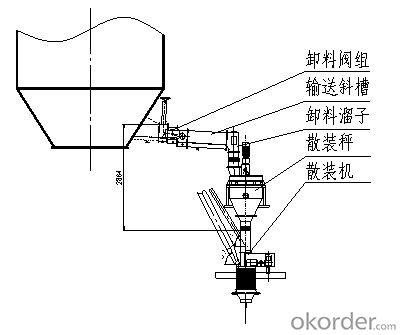

KXT (SZ) Cement Bulk Dosing and Control System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Portland KXT (SZ) cement bulk dosing and control system, for the first time to realize cement bulk and weigh integration in China. Powder business measurement technology is outshine domestic others.

1、 Product introduction

Since 1996, Portland carry out coriolis powder material measurement technology and related products production. With this company for cement production process, measuring principle, equipment design, automatic control method and other related professional comprehensive advantages, a batch of long engaged in cement production technology research of experts to pursuit technical progress, through efforts, we achieve success in the test method and signal processing scheme of key area of technology, successfully developed a new generation of large flow powder material measurement system - bulk cement measurement system that can be used in commercial measurement, realized the cement bulk and measurement integration, accuracy of measuring achieve plus or minus 0.5%.

The cement bulk metering system, can be used in bulk vehicle filling and loading quantity measurement, change the tradition that loading and measurement that is measured by the electronic platform scale is respective. The system also can be applied to cement bulk ship loading and quantity measurement.

2、Product features

“Cement bulk metering system" make bulk cement become simple and science, to solve the problem that there are many traditional ways,the efficiency is low, the human interference factors and so on.

"Cement bulk metering system" is a complete data processing and management system, including bulk process control, unit bulk quantity monitoring and display, bulk dynamic accumulative total, support data upload, etc.

"Cement bulk metering system" is not only used in one car is filled, but also used in finishing bulk process according to the requirements of the load.

"Cement bulk metering system" measures powder material flow by coriolis mechanics principle, and its accuracy is better than the plus or minus 0.5%. The measurement is accuracy, process is simple, layout is compact, convenient in maintenance, Accuracy of measuring, bulk and measurement rate, system reliability and other technical indexes is better than similar products.

"Cement bulk metering system" is also applied to railway, port, wharf, mining, metallurgy, chemical fertilizer, power, light industry etc powder and granular materials bulk measurement link, measuring ability ~ 800 m3 / h.

3, system function and technical features

——Realization of bulk cement continuous, uniformity and stability of feeding;

——To fill one car as the goal, accurate measurement for bulk cement loading quantity;

—— To quantitative loading as the goal, according to the setting loading quantity to quantitative accuracy control bulk cement loading.

—— To achieve the lower and upper limit alarm, data can be storage longly after power off, support data upload and instant printing function.

Measuring accuracy: ≤± 0.5%

—— Applicable material: moisture<3%, particle size 5mm

——Weighing range: 0~250t/h

——Use environment: temperature - 20 ℃ ~ 60 ℃, relative humidity 95% or less

4、service condition

since July 2010 ,"Cement bulk metering system" has saled 24 sets, the repercussions are good. The GUANDDONG QINGYUAN GUANGYING Cement co., LTD. has chosen 6 sets of KXT (SZ) - 250 cement bulk metering system, used in good condition.

- Q: What is a forklift? Forklifts are special equipment

- Hello, forklift truck is an industrial transport vehicle, which is a variety of wheeled transport vehicles for loading and unloading, stacking and short-range transportation. The forklift is a kind of special equipment management. Type: special motor vehicle in field (factory) Category: motor vehicle Varieties: forklift The operators must have the quality technical supervision bureau issued: Special equipment operator certificate Special motor vehicle operation in field (factory) Work item: forklift driver

- Q: What is the rational and scientific classification of logistics facilities and equipment

- The operation of loading and unloading and transportation activities in the field of logistics is determined by the smooth operation of the logistics industry. The carrier is divided into two parts: one is handling and handling machinery; Second, transport machinery. Loading and unloading machines include: crane, forklift, container handling and pallet shipment. Transport machinery such as: road transportation of all kinds of truck, train of railway transportation, water transport ships, air transport aircraft, pipeline transport pipeline, and so on. With the development of logistics informatization, networking and systematization, the computer plays an important role in logistics management. Communication devices include telephone, telegraph, e-commerce, wireless tower and so on. Computer and communications equipment connect the whole world of life, culture, politics, economy as a whole, shortens the distance of time and space, we can timely and accurate understanding of the external environment and information and change.

- Q: The material needs to be transported, it is easy to produce dust.

- Hello! There are many successful users in the coal-mining plant, such as shenhua, jun, Venus, and extended oil. Before choosing the right device, you need to specify two things: Objective conditions: the operating conditions of the factory, the layout of the workshop space, the material situation and the capability requirements, which conveyance equipment is currently used.

- Q: The wear-resisting parts in the broken machine are mainly the direct contact with the material

- There is a need to contact, the crusher is a lot of model and the performance is different. For example: the jaw is broken, the hammer is broken, the fight is broken, the cone is broken... It is. Wear-resisting material is different also, also need according to the material hardness, strength of the material that is broken, the choice is ok. Materials: alloy white iron (high chromium cast iron), high manganese steel, alloy steel (high, medium, low carbon and alloy)... It is. It's best to find experienced manufacturers. Hope to adopt.

- Q: The development of material handling

- The material handling equipment manufacturing industry provides various kinds of modern transportation equipment for the national economy, major construction projects and national defense security. Basic formed a comprehensive product range, good technical system and large enterprise groups, become an independent industry, machinery industry in the service of national economy in all walks of life, including for the second and the third industry provides a huge number, a great variety of products, can independently or with foreign cooperation for national key project to provide large lifting transportation machinery and complete sets of equipment system, and have a certain amount of exports. In 2011, there were 1,580 enterprises in the manufacturing industry of material handling equipment in China (RMB 20 million), and more than 400 000 employees. The industry realized sales revenue of 4723.47 billion yuan, with an industrial output value of 4712.23 billion yuan, with a total profit of 34.50 billion yuan, with an average annual compound growth rate of over 20%. With the expanding of the scale of production, improve degree of automation, material handling equipment manufacturing industry is more and more widely used in the process of modern production, function more and more big.

- Q: The beneficial effect of material handling machinery

- Material handling machinery is serving the production, its design and type selection should be subject to the needs of the production process, new material handling machinery but also often leads to the change and improvement of the manufacturing process. For example, the emergence of bucket wheel stacker reclaimer, formed the bucket wheel stacker reclaimer for heart, belt conveyor for blood vessels, the electronic computer is the nerve center of automation of large bulk material handling system, which changes the ports, mines and the layout of the power plant and so on of the bulk yard; It can simplify the structure of the factory and reduce the cost of construction.

- Q: The principle of material handling

- Adaptive principle (flexibility principle) : adopt methods and devices that can adapt to various kinds of work and applications, unless it is a device that must be used for a particular purpose. Reduce the principle of self-importance: reduce the ratio of air to heavy load. Principle of utilization: the optimal utilization rate of planning and carrying equipment and manpower. Maintenance principle: plan all the maintenance and maintenance of all moving equipment. Obsolete principle: replace outdated methods and equipment when there are more efficient means of handling and equipment. Control (control) principle: use material handling activities to improve control of production, inventory and order processing. The principle of production ability: use the handling equipment to improve the production capacity.

- Q: What is the carrying equipment of the container cargo

- Container (container), crane, forklift truck Kunshan city peng a lift lifting transportation and handling professional clean room equipment installation, precision air handling import and export container, unpacking, assembling positioning, whole factory move, special lifting engineering contracting, precision machine packed in wooden cases

- Q: There are three things to do when the material is stacked up and down

- Fire prevention, waterproof, and do not exceed the limit.I hope my answer will help you.

- Q: What are the requirements for the science of loading and unloading

- Use material handling activities to improve control of production, inventory and order processing. Use the transport equipment to improve the production capacity. The cost of moving the unit to determine the performance of the transport. Provide appropriate means and equipment to enhance the handling safety.

Send your message to us

KXT (SZ) Cement Bulk Dosing and Control System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords