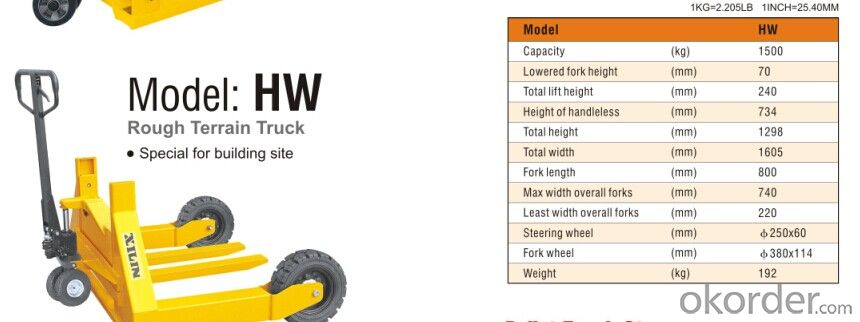

HW MULTI-FUNCTION HAND PALLET TRUCK

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: What are the potential defects of the automated material handling system?

- The automatic stacker is a stack of finished goods that will be wrapped in a sealing machine, and the finished product will be finished by the machine hand. Demolition yards of technical difficulty than pallet, the main reason is that the original pallet good tray due to finished product deformation and vibration in the transport process, make product tray deformation, cause every demolition yards of finished tray deviating from the ideal position. In addition, due to the demolition yards tray is finished box close to finished product box, general instrument cannot be inserted between the two cases, make clamping product box, the solution is to use a vacuum sucker is finished. The mechanical manual stacker has the following advantages compared with the traditional high stacker machine. Secondly, the failure rate is low; Third, the area is small. Fourth, the cost of human resources is low.

- Q: What is a forklift? Forklifts are special equipment

- Project code: N2 See the general administration of quality inspection (aqsiq) for the announcement of the "special equipment catalogue" in 2014 Definition of special motor vehicle in field (factory) : Special motor vehicles, in the field (factory) is refers to besides the road traffic, agricultural vehicles in the plant, scenic spots, only used in certain area such as amusement places of special motor vehicles.

- Q: What is the rational and scientific classification of logistics facilities and equipment

- Generally be divided into logistics facilities and equipment, logistics equipment, logistics, warehouse facilities and equipment, logistics transportation facilities and container handling equipment, logistics equipment, logistics, circulation unitized equipment, port logistics facilities and equipment processing equipment, automatic sorting equipment, information platform and equipment. Logistics infrastructure refers to the service function of a supply chain and some of the supply chain process, meet the need of logistics organization and management, which has the function of comprehensive or a single place or organization collectively, mainly including roads, railways, ports, airports, distribution center and network communication, etc. Logistics infrastructure includes warehousing, delivery facilities, and computing and information communication equipment.

- Q: The wear-resisting parts in the broken machine are mainly the direct contact with the material

- There are many different types of crusher and different performance. For example: the jaw is broken, the hammer is broken, the fight is broken, the cone is broken... It is. Wear-resisting material is different also, also need according to the material hardness, strength of the material that is broken, the choice is ok. Material: white iron, alloy white iron (high chromium cast iron), high manganese steel, alloy steel (high, medium, low carbon and alloy)... It is. Prices are different because of different materials. Otherwise "overqualified person" not to calculate, "small material big use" not only use not, also do not calculate.

- Q: Why should we emphasize unitization and standardization in material handling

- Unitization is the application of scale thought to different materials. We can simplify the links, save the cost, and realize the overall optimization. To facilitate the mechanization of loading and unloading, reduce the labor intensity and improve the efficiency of the work. Reduce the damage caused by the transformation and improve the quality of logistics.

- Q: The function of material handling

- The logistics of mechanical products are very broad and the principle of improving the logistics system is: It enhances the operational training and safety of the handling personnel and increases the efficiency of labor.

- Q: The beneficial effect of material handling machinery

- Material handling machinery is serving the production, its design and type selection should be subject to the needs of the production process, new material handling machinery but also often leads to the change and improvement of the manufacturing process. For example, the emergence of bucket wheel stacker reclaimer, formed the bucket wheel stacker reclaimer for heart, belt conveyor for blood vessels, the electronic computer is the nerve center of automation of large bulk material handling system, which changes the ports, mines and the layout of the power plant and so on of the bulk yard; It can simplify the structure of the factory and reduce the cost of construction.

- Q: Material handling system in the factory

- The machinery factory's internal logistics system involves the production plan, process flow, moving operation, warehouse management, information system and so on.

- Q: The principle of material handling

- The principle of the effectiveness of the handling operation: the cost of carrying the unit to determine the performance of the transport. Safety principle: provide proper means and equipment to enhance handling safety.

- Q: What are the requirements for the science of loading and unloading

- Reduce the load ratio of the mobile carrying equipment. To optimize the utilization rate of transportation equipment and manpower. Plan all the equipment to be maintained and maintained regularly. When there are more efficient means of handling and equipment, it should replace obsolete methods and equipment.

Send your message to us

HW MULTI-FUNCTION HAND PALLET TRUCK

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords