Multi Layer Composite DN Size FRP Pipe with Sand Filler

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Kinds of DN Size FRP Pipe Description

FRP pipe is in the filament winding process, using quartz sand layer will strengthen, make its have sandwich structure, such as reducing the comprehensive cost of the pipeline, and improve the overall strength and stiffness of the pipeline.

2. Main Features of Kinds of DN Size FRP Pipe

1) Light weight, high strength, and convenient transportation and installation.

2) Excellent corrosion resistant, it can be used under the condition of seawater environment for long time.

3) Good low temperature resistant, it can be used under the condition of -45°C-120°C for long time.

4) Smooth inner surface, its roughness coefficient is 0.0084, good conveying, and no fouling, no secondary pollution, decrease the cost of the running & maintenance.

5) Fire retardant, it meets IMOA.753(18) Level-3 fire resistance class.

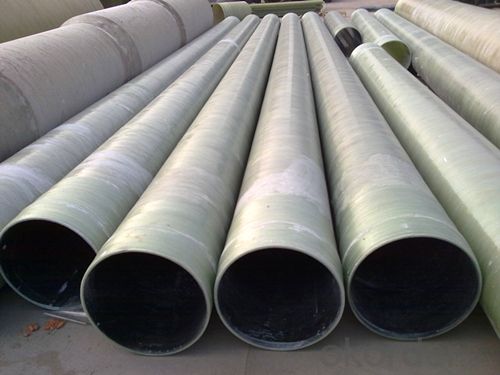

3. Kinds of DN Size FRP Pipe Images

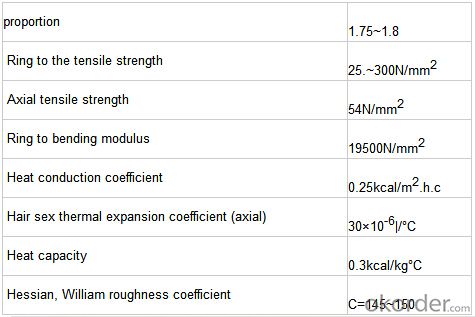

4. Kinds of DN Size FRP Pipe Physical Properties

5. FAQ of Kinds of DN Size FRP Pipe

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

One of the leading manufacturers and suppliers specializing in FRP pipe products in China. The integrated sales & service ensures customers with various demands an easier access for purchasing management.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: What are the functions of glass fiber reinforced plastics?

- The jet can reduce the weight of the aircraft by using it as an oil tank and pipe. Astronauts aboard the moon, who carry miniature oxygen bottles on their backs, are also made of glass fiber reinforced plastic. Glass fiber reinforced plastics are easy to process, stainless, and do not need paint. Our country has been widely used in glass steel manufacturing all kinds of small boats, boats, yachts, and automobile manufacturing, save a lot of steel.

- Q: The difference between FRP process tubes and GRP tubes

- Process tubes are mostly pure glass steel, not sand, and sand pipe, of course, is added sand.

- Q: Raw material and mix ratio of inorganic glass fibre reinforced plastic wind pipe

- In order to improve the quality of glass.Advanced technology may be used.The ratio seems to be 1 to 0.001. Pretty much within this range.

- Q: What are the standards for FRP pipes?

- In order to comprehensively check the installation quality of the pipeline, it is necessary to carry out a comprehensive examination according to the test methods stipulated in the code for construction and acceptance of water supply and drainage pipeline works and to carry out the water pressure test. Permissible water seepage can be carried out according to the standard of FRP pipe.

- Q: CGCT what's the meaning of the GRP sand pipe?

- Glass reinforced plastic sand pipe is actually in the production of glass fiber reinforced plastic pipe, in the middle to increase a layer of sand layer, the purpose is to increase the rigidity of the pipeline.

- Q: How can I make up the broken glass fiber?

- If the glass fiber reinforced plastic pipe is broken, how do you fix it and repair it better?. It's better to replace it. I wonder how much pressure you use for fiberglass pipes. The proposal is to replace the pipeline.

- Q: How to open a DN300 port on the DN600 GRP pipe and install the DN300 gate?!

- Do not know the road of glass steel flange have, if any to buy different materials of cast iron flanges or PVCU flange on the same material, the three way behind the pipeline branch, so that the material market has purchased (ABS buy buy in the small town is not easy), the construction is convenient. If it is a glass steel pipe, pipe end cannot change, can only be used to bond the glass steel material, the pipe bonded on the flange is an arc for a plane is bonded with a cast iron pipe flange suggestions. Because the FRP material and most of the plastic are not bonded.

- Q: Glass fiber reinforced plastic pipeline to do anti-corrosion?

- Glass fiber reinforced plastic itself belongs to a kind of anticorrosive material, and usually needs no antiseptic treatment. However, mainly depends on the environment and requirements.

- Q: Who knows, how is the glass reinforced septic tank connected with the municipal pipe?

- If a glass fiber reinforced plastic outlet pipe is reserved, a new sewage inspection well is installed at the pipe end, and then a sewage pipe is installed to connect the reserved manhole of the municipal sewage pipe.

- Q: What's the price of fiberglass reinforced sand pipes?

- This depends on the specific size of the caliber you want, how much thickness, specifically for you to quote. If you have any questions, you can talk to me privately.

Send your message to us

Multi Layer Composite DN Size FRP Pipe with Sand Filler

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords