Composite Pipes - FRP Pipes Filament Winding FRP Pipe with Sand Filler

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

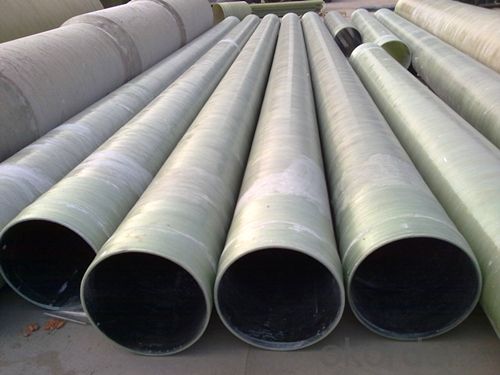

1. Structure of Filament Winding FRP Pipe Description

Production Range: Diameter: DN 40-800mm, Pressure Rating: PN 3.5-25Mpa

Implemented Standards: 1) API15HR 2) API15LR

Temperature-resisting Grade:

Long-term working temperature range of anhydride cured epoxy system ≤65°C, the maximum temperature 80 °C.

Long-term working temperature range of amine cured epoxy system ≤93.3°C, the maximum temperature 135°C.

The minimum working temperature range of Epoxy FRP pipe products ≥-35°C

2. Main Features of Filament Winding FRP Pipe

1) High corrosion resistance

2) Excellent fatigue durability, 20 years design service life.

3) Strong bearing, high safety coefficient

4) Light weight, easy installation

5) Fine tightness connected with steel pipe

6) High, middle, low pressure rating satisfy different medium delivery.

7) No electrical conductivity, smooth internal surface and low friction coefficient, high delivery efficiency.

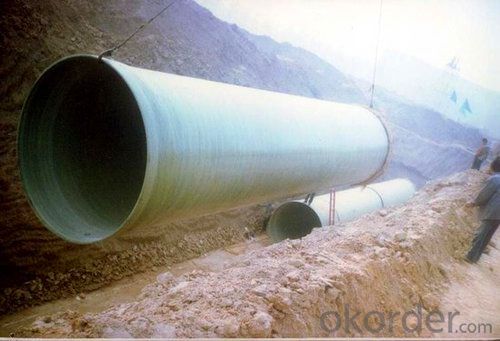

3. Filament Winding FRP Pipe Images

4. Filament Winding FRP Pipe Application

1) Oil or gas transportation lines.

2) Chemical treatment and sewage pipelines.

3) Fluid transportation lines of high, medium and low pressures.

4) Oily water injection lines.

5) Injection lines for tertiary recovery(Injection of polymer, CO2 , NaOH etc.).

6) Tubing for oil producers, tubing for injectors of salty, chemical or oily water, CO2 and polymer.

5. FAQ of Filament Winding FRP Pipe

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

One of the leading manufacturers and suppliers specializing in FRP pipe products in China. The integrated sales & service ensures customers with various demands an easier access for purchasing management.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: Designed to support FRP pipes, is it m or mm?

- The glass steel pipe wall smooth, do not scratch the cable, socket type interface, convenient installation and connection to thermal expansion and contraction, the proportion of small, light weight and reduce installation labor, reduce the cost of installation, FRP cable protection pipe used for electric power, communication cable, in various environmental protection pipe laying cables, especially through the traffic crossing to the cable across the river the use of the bridge, under special circumstances, can fully reflect its simple construction, high strength, excellent performance, widely used in electric power, communications, transportation, civil aviation, airport infrastructure and other Domain company always adhere to the "customer first, integrity management, intentions services for business philosophy, is willing to work with friends from all walks of life to strengthen cooperation, mutual cooperation, common progress and win-win

- Q: Glass fiber reinforced plastic sand pipe backfill 5m, how much kg pressure?

- These two parameters are based on the need and the actual geological situation to determine, not a backfill a few meters can be determined.

- Q: The difference between GRP cable duct and PVC cable pipe

- PVC cable pipe refers to various kinds of rigid PVC pipes made of PVC resin as main raw material and various stabilizers.

- Q: The outer thermal protection layer of the pipeline is made of GFRP. Which guy knows the construction method?

- The basic thing is to finish the heat preservation. Soak the PP cloth soaked in the solution and finish it. Then brush it one or two times. The key is to make the solution, with water heating method, or else not. If you want to strengthen the strength, you can finish the insulation, and then wrapped a layer of 10---20 purpose wire mesh, and then made glass fiber reinforced plastic

- Q: Pipe installation of glass fibre reinforced plastic pipe

- The pipe connected with the transmission equipment shall be clean before installation, and the welding fixing pipe shall be far away from the equipment in order to avoid the influence of welding stress on the installation accuracy of the transmission.

- Q: What epoxy resin is used for anticorrosion of pipeline glass fiber reinforced plastics?

- 3PE has been anti-corrosion principle, there is no need for anti-corrosion, but now the domestic situation. Directional drilling pipe cannot be detected and repaired, the anticorrosion layer cannot have serious damage to the pipeline, long-term safety operation, it should be required for coating directional drilling: scratch resistance, abrasion resistance, impact resistance, high hardness, strong adhesion and pipeline, corrosion resistance, water resistance have a good soak, matching and cathodic protection system.

- Q: What are the construction methods of glass fiber reinforced plastic paint anticorrosive pipes?

- Epoxy coal tar pitch is a kind of anti-corrosion form with high cost performance. The engineering test shows that the epoxy coal asphalt is used as cathodic protection.

- Q: How to improve the compressive strength of waste glass fiber reinforced plastic profiles (such as square tubes) should be started with resin, curing agent, glass fiber or other aspects!

- Ensure the solidification of glass steel products in a reasonable range, in general, glass fibre reinforced epoxy resin material curing degree if the use of amine curing agent, the best curing degree in the range of 135 degrees --150 degrees, polyester resin, Mohs hardness of about 60 is OK.

- Q: What is the thickness of all types of FRP pipes?

- The standard effective length of the tube is 6m and 12M, and the production methods include fixed length winding process, centrifugal casting process and continuous winding process of three kinds. Classification can be carried out according to the product process method, pressure grade PN and stiffness grade SN.

- Q: What are the posts of glass fiber reinforced plastic sand pipe and the corresponding occupational hazards and protection?

- Glass fiber reinforced mortar pipe lightweight high strength: for the same diameter of the unit length, weight, RPM tube only carbon steel 1/3, cast iron pipe 1/5, prestressed concrete pipe 1/10, easy transport, loading and unloading.

Send your message to us

Composite Pipes - FRP Pipes Filament Winding FRP Pipe with Sand Filler

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords