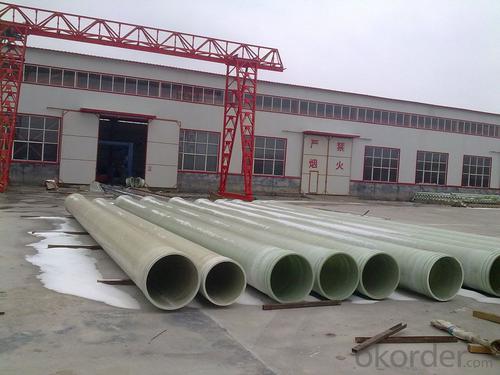

Multi-Layer Composite FRP Pipe with Excellent Mechanical and Physical Performance

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

1.Pipe Introduction

It is the ideal product for the transportations of the chemicals, drinking water, waste water, waste gas and sewer.

2.Characteristics

• Corrosion resistance High mechanical property

• Low friction coefficient

• Light weight

• Non toxic

• Maintenance free

• Long life span

• Double O ring sealing joint make the pressurization

more convenient and unique.

• Convenient and quick installation

• Long life of more than 50 years

Stiffness | SN3750 | SN5000 | SN10000 | ||||||

Pressure | 0.25 | 0.6 | 1.0 | 0.25 | 0.6 | 1.0 | 0.25 | 0.6 | 1.0 |

400 | 6.1 | 6.1 | 5.9 | 6.7 | 6.7 | 6.4 | 8.1 | 8.1 | 7.87 |

500 | 7.2 | 7.2 | 7.1 | 8 | 8 | 7.7 | 11.4 | 9.6 | 9.4 |

600 | 8.7 | 8.3 | 8.3 | 9.6 | 9.6 | 9.2 | 12.1 | 11.7 | 11 |

700 | 9.7 | 9.7 | 9.4 | 11.2 | 11.2 | 10.4 | 13.8 | 13.2 | 12.5 |

800 | 11.6 | 11.3 | 10.6 | 12.8 | 12.5 | 11.7 | 15.5 | 15 | 14.2 |

900 | 13.4 | 12.5 | 11.7 | 14.8 | 13.8 | 12.9 | 19.3 | 16.4 | 15.8 |

3.Production range

Any type and specification RPMP of diameter DN400-DN4000 and pressure PN0.25-PN2.5MPa can be produced.

Also, we can provide the customized product according to user’s specific requirements.

COMPANY DESCRIPTION

CNBM, China National Building Materials Group is a state-owned enterprise in charge of administrative affairs in china building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely owned and joint-venture companies.

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products, professional service and complete solution to our customers. Strong delivery capacity, advanced technology & management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

PACKAGING & DELIVERY

Packaging Details:

plastic film and pallet

Delivery Detail:

In 5 days after receiving the down payment

FAQ

1.Q:Are you factory or trading company ?

A:We are Factory produce frp machines and frp products.

2.Q:If can customzied by customers requirements?

A:yes,we can produce the machine with customized size.

3.Q:How about the payment?

A:We accept any kind of payment.

4.Q:What is the guarntee?

A:Gurantee is one year.

5.Q:If you can training?

A:yes ,we can training in our factory also can send engineers to your factory training.

- Q: Why FRP pipes for outdoor waste gas treatment equipment are selected?

- Relative to the iron and steel materials such as glass, steel price is the highest, and can reach more than 25 years of life in the outdoors; other materials, such as: PP material, although very similar characteristics of steel and glass, but there is a fatal flaw: the outside is very easy to be corroded and aging, especially direct sunlight high and low temperature conditions, the service life is often less than two years.

- Q: Winding method of glass fibre reinforced plastic pipeline anticorrosive glass fiber cloth

- When the length and width of glass fiber mesh are not enough, the method of lap joint must be adopted to improve the tangential bearing capacity of the joint, so as to effectively overcome the radial tensile stress, bending force and bending shear stress. The lap length of the glass fiber cloth at the joint is generally 50 to 100mm, and the joint of each glass fiber cloth should be at a certain distance from the adjacent joint. The longitudinal and transverse joints between adjacent layers shall be greater than 300mm, and the distance from the same seam shall not be less than 500mm.5) paste made of circular duct, glass cloth along the radial 45 degree angle to the direction of cut cloth; conical paste products, according to the fan-shaped cloth.

- Q: What are the functions of glass fiber reinforced plastics?

- The jet can reduce the weight of the aircraft by using it as an oil tank and pipe. Astronauts aboard the moon, who carry miniature oxygen bottles on their backs, are also made of glass fiber reinforced plastic. Glass fiber reinforced plastics are easy to process, stainless, and do not need paint. Our country has been widely used in glass steel manufacturing all kinds of small boats, boats, yachts, and automobile manufacturing, save a lot of steel.

- Q: What are the differences between inorganic FRP pipes and plexiglass pipes, what are the advantages and disadvantages?

- Inorganic glass fiber reinforced plastic wind pipe: magnesium magnesite soil and glass fiber mesh cloth made of advantages: flame retardant shortcomings: large proportion, low strength

- Q: What can be done to solve the leakage of FRP pipe?

- DN1800 FRP pipe pressure of 9 kilograms, the pressure is very high, crushed by stones, not repaired will certainly leak, the pressure pipe leakage is very bad, will be washed away the soil, spewing a few meters high water column.

- Q: The outer thermal protection layer of the pipeline is made of GFRP. Which guy knows the construction method?

- Usually with aluminum or iron sheet, with glass or steel, or the first time, I'm afraid the toughness is not enough.

- Q: What's the difference between glass fiber reinforced plastic pipe and glass fiber reinforced sand pipe?

- If the thickness of the pipe can meet the requirements of pressure, but can not meet the stiffness requirement, will choose to increase the thickness of sand to meet the stiffness (of course can not directly increase the sand thickness to meet the requirement of stiffness, but the cost is too high).

- Q: How to improve the compressive strength of waste glass fiber reinforced plastic profiles (such as square tubes) should be started with resin, curing agent, glass fiber or other aspects!

- Use a high strength resin type;

- Q: What is the compressive strength of all kinds of FRP materials?

- Heat resistance, frost resistance: at -30 DEG C, still has good toughness and high strength, can be used for a long time in the range of -50 DEG C 80 DEG C, the temperature of resin with special formula can be more than 110 DEG C. 4) of light weight, high strength, convenient transportation and installation by fiberglassreinforcedplastic pipe winding fiber production, the proportion of 1.65 - 2, 1 / 4 only of steel, but the glass steel hoop tensile strength is 180 300MPa, the axial tensile strength of 60 150MPa, similar to alloy steel. Therefore, its specific strength (strength / density) is 2-3 times that of alloy steel, so that it can be designed according to different requirements of users to meet all kinds of internal and external pressure requirements of the pipeline. For the same diameter of single FRP tube, only carbon steel (steel plate) 1 / 2.5, 1 / 3.5 of the cast iron pipe, about 1 / 8 of prestressed reinforced concrete pipe, so the transportation is very convenient for installation. The GRP pipe is 12 meters per length, and can be reduced by 2/3 from the concrete pipe. The socket connection mode of the utility model has the advantages of quick and simple installation, low hoisting cost and improved installation speed. 5) small friction resistance, high transport capacity: glass tube wall is very smooth, roughness and friction resistance is very small. The roughness coefficient is 0.0084, while the n value of concrete pipe is 0.014, and the cast iron pipe is 0.013. Therefore, glass fiber reinforced plastic pipe can significantly reduce the loss of fluid pressure along the course and improve the conveying capacity.

- Q: A basic overview of FRP pipes

- FRP pipes are made of resin (feed water, food grade resin), glass fiber and quartz sand as raw materials and made by special process.

Send your message to us

Multi-Layer Composite FRP Pipe with Excellent Mechanical and Physical Performance

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords