JIS Standard 10 K Butterfly Valve With Double Flange

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 200 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

JIS Standard 10 K Butterfly Valve With Double Flange

The Butterfly Valve Standard

Designed: API609, ASME B 16.34, AWWA C 504, BS EN593

Face to Face: API 609, AWWAC504, BS2080, and ISO5752

Flange End: ASME B 16.5, ASME B 16.47, BS EN1092, ISO7005

Inspection Test: API 598, BS EN 12266, ISO 528

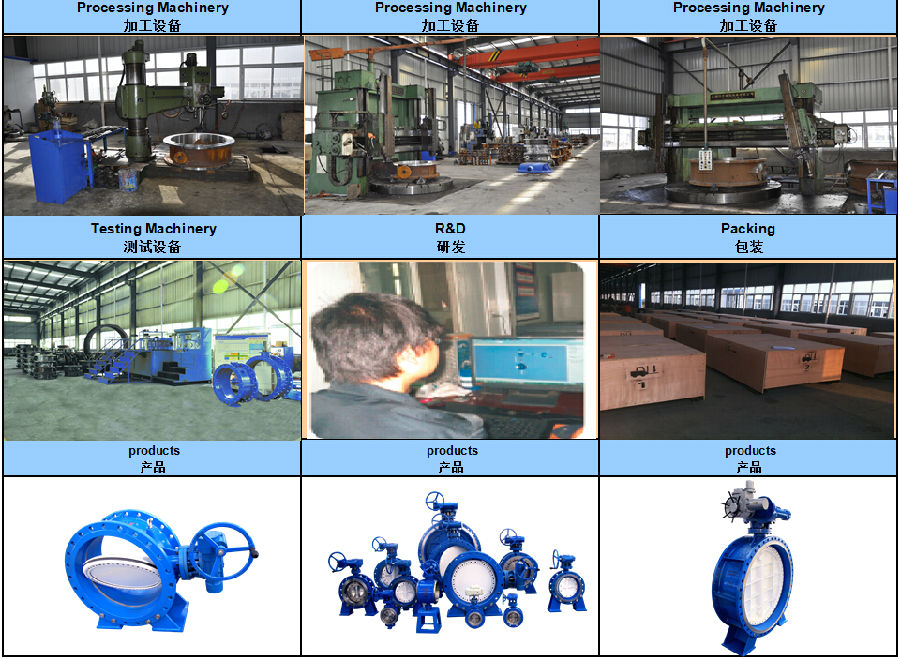

Materials Choose

Body Materials: WCB/WCC/LCB/QT450-10/QT500-7/CF8M/CF3M

Disc Materials: WCB/WCC/LCB/QT450-10/QT500-7/CF8M/CF3M

Seat Materials:304/316/Graphite/Asbetos/PTFE

Specifications

Pressure: PN10/PN16/PN25/CL150/CL300

Size: DN40---DN3200

Drive Mode: Manual/Worm gear/Electric/Pneumatic

Field of Application: Electric /Hydraulic/Municipal Engineering etc; Water/Sea water/Gas etc.

Delivery: within 15-30days after receipt of at sight L/C or 30% as advance payment by T/T

Butterfly Valve Packing: Seaworthy packing:

1. Single Butterfly Valve is packed with foam plastic bag.

2. Put sponge in each floor

3. Electric or pneumatic actors will Individual packaging it with wood box.

4. Export Wooden Packing

5. We can pack according to specific customer requests.

6. Customers’ logos are available on package.

7. Design and manufacturing the wood box to save the sea cost if needed .

- Q: For whatever reason, Mazda has made it next to impossible to change the PCV valve on the 929. I'm going to have to pull off the plenum and the passenger's side valve cover to replace a $2.00 PCV valve. Before I get too involved, I need to know the torque specs for the valve cover. Also, any other tips on this process would be greatly appreciated. Can I reuse the old valve cover gasket if it's still in good shape? Should I use any kind of sealant in addition to the gasket when I put it all back together? Thanks in advance, by looking at this motor, I can tell I'll have my work cut out for me (for a friggin $2.00 PCV valve, it's usually SO simple!). Like I said, any and all help is greatly appreciated.

- you do not torque valve covers down, buy a new gasket , I would get a good quality rubber one and some blue rtv sealer, clean any crap off the valve cover no glue no bits of gasket nothing, same thing on the head surface, glue the gasket on the valve cover, let it set, then carefully put it on, start with the bolts in the middle and work out finger tight all of them, then just snug the bolts down, dont crush the gasket, you can also use a light duty locktite to hold them in place, and often times old valve covers are warped, it is too your advantage to make sure its as flat as you can get it, or spend a few bucks a buy a new one. your choice, but snug the nuts down good with out crushing and bending the thin sheet metal of the valve cover.

- Q: Is the pressure test of the centerline butterfly valve checked or checked?

- Every factory factory must require pressure tests.

- Q: How does PLC control butterfly valves?

- PLC output signal, access to the butterfly valve actuator or locator, you can control

- Q: What is the butterfly valve

- Conclusion: Although the double valve advanced technology, metrology, but must ensure stable and timely flow of materials, in order to achieve good results, so the combination of flotation system and dual use of butterfly valve can fundamentally solve the flow and measurement of powder, so as to rely on self weight principle of materials, so we plant layout the middle of a large number of mechanical equipment to save not only, more important to reduce the cost of investment and running.

- Q: Butterfly valve D71X-1.6C, DN50, there is no difference between C and no C? What do you mean by "concrete"?

- D stands for butterfly valve. 71 represents the clamp type, X represents the sealing surface material, and 16 represents the valve to bear the pressure 1.6MPA, C position is the valve body material code, omitted to represent gray cast iron valve; C represents the valve body material is carbon steel.

- Q: Butterfly valves are widely used in 2.0MPa below the pressure and temperature of not more than 200 degrees of various media, right?

- 5. butterfly valve structureButterfly valve mainly by the body, butterfly plate, stem, sealing ring and transmission components.(1) the valve body is cylindrical, and the upper and lower parts each have a cylindrical boss for installing the valve stem. Butterfly valve and pipe flange connection, such as the use of clamp connection, the minimum length of its structure.(2) stem, stem is the axis of the butterfly plate, shaft end adopts stuffing box sealing structure, can prevent leakage of medium. The upper end of the valve stem is directly connected with the driving device to transmit the torque.(3) the butterfly plate is the opening and closing part of butterfly valve.

- Q: what are the step i need to do so i can change the valve seals my truck has been smoky.,,, any websites i want todo it myself... 1989 chevy silverado 2500 350 engine 5.7L

- bypass purchase a Haynes or Chilton handbook. they're the suitable components of education for this undertaking. If i attempted to element this education here it might take all night to describe all of it.

- Q: Butterfly valve sealing material has several?

- 9: H- stainless steel composite layerX3- ethylene propylene rubberX4- chloroprene rubberX5- nitrile rubberX6- abrasion resistant rubberX7- fluorine rubberX8- silicone rubberX9- heat resistant ethylene propylene rubberF- PTFE

- Q: Who was the first doctor to discover Pulmonary Valve Stenosis? Also, who was the first doctor to perform surgery for it? Please and thank you for your help.P.S. I have this condition.

- 1761 - Pulmonary valvar or valvular stenosis is one of the more common forms of congenital heart malformations and it has been extensively studied since the original description of pulmonary valve stenosis by John Baptist Morgagni in 1761. 1888 - Tetralogy of Fallot, first characterized by Dr.Etienne Fallot in 1888, is present in about 3000 children born each year in the United States. It is a combination of four heart abnormalities. Dodrill and his colleagues employed it with success for the open correction of a stenotic pulmonary valve in October 1952.

- Q: butterfly valves d7a1x5

- D- valve type (butterfly valve), 7- connection mode (to clamp), A- valve shape mode (A), 1- structure form (vertical plate), X5- valve seat sealant species (Ding Qing, NBR)

Send your message to us

JIS Standard 10 K Butterfly Valve With Double Flange

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 200 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords