JIS G3302 Hot Dipped Galvanized Steel Coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

JIS G3302 Hot Dipped Galvanized Steel Coil

Specification

Hot Dipped galvanized steel coil

1. Thickness: 0.16-3.0mm

2. Width: 610-1250mm

3. Coil Wgt.: 2.5-8Mt

4. Zn Coating: 60-300

Galvanized Steel Coil Technical Data

Chemical Composition | ||||||

GRADE | C | Si | Mn | P | S | Ti |

SGCC/DX51D+Z | ≤0.10 | ≤0.50 | ≤0.60 | ≤0.10 | ≤0.030 | ≤0.020 |

DX52D+Z | ≤0.10 | ≤0.50 | ≤0.60 | ≤0.10 | ≤0.030 | ≤0.020 |

SGCD/DX53D+Z | ≤0.10 | ≤0.30 | ≤0.50 | ≤0.05 | ≤0.030 | ≤0.020 |

SGCE/DX54D+Z | ≤0.10 | ≤0.30 | ≤0.30 | ≤0.03 | ≤0.020 | ≤0.020 |

DX56D+Z | ≤0.10 | ≤0.30 | ≤0.30 | ≤0.03 | ≤0.020 | ≤0.020 |

Structural | ≤0.20 | ≤0.60 | ≤1.70 | ≤0.10 | ≤0.045 | |

Mechanical Properties | ||||||

GRADE | Yield Strength MPa | Tensile Strength MPa | Elongation % | |||

SGCC(DX51D+Z) | ≥205 | ≥270 | - | |||

SGCD(DX53D+Z) | - | ≥270 | 38 | |||

SGCE(DX54D+Z) | - | ≥270 | 40 | |||

DX56D+Z | - | ≥270 | 42 | |||

GRADE | Yield Strength MPa | Tensile Strength MPa | Elongation % |

S220GD | ≥220 | ≥300 | ≥20 |

S250GD | ≥250 | ≥330 | ≥19 |

S280GD | ≥280 | ≥360 | ≥18 |

S320GD | ≥320 | ≥390 | ≥17 |

S350GD | ≥350 | ≥420 | ≥16 |

Galvanized Steel Coil Application

(1) Guardrails, roofing, ventilation ducts, gutters and down spouts;

(2) Pre-paint and post paint applications, ceiling suspension bars, shutter door rails;

(3) Auto parts, electrical appliances, refrigerator appliances, vending machines, washing machines, showcases and other structural use.

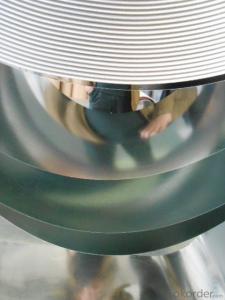

Galvanized Steel coil Show

- Q: How are steel coils used in the production of agricultural trailers?

- Steel coils are used in the production of agricultural trailers to provide strength and durability. The coils are shaped into various components of the trailer's structure, such as the frame and chassis. This ensures that the trailer can withstand heavy loads and rough terrain, making it suitable for transporting agricultural equipment and produce.

- Q: How are steel coils used in the manufacturing of HVAC ductwork?

- Steel coils are used in the manufacturing of HVAC ductwork as they provide the necessary strength and durability required for the ductwork. These coils are typically processed through a roll-forming machine, which shapes them into the required ductwork profile. The steel coils are then cut to the desired length, welded or joined together, and finally, coated to prevent corrosion and improve the overall performance of the ductwork.

- Q: How are steel coils used in the production of railway tracks?

- Railway tracks rely heavily on steel coils, which are indispensable in their production. These coils, typically made from top-notch steel, are utilized to create the rails that constitute the bedrock of the tracks. The process commences with the unwinding of the steel coils, which are then fed into a sequence of machines that mold and fashion them into the desired rail profile. Initially, the steel coils are passed through a rolling mill, where they undergo gradual flattening and shaping, thereby transforming into elongated steel strips. This technique, known as hot rolling, involves heating the steel to high temperatures to enhance its pliability. The rolling mill exerts substantial pressure on the steel, progressively molding it into the desired rail shape. Once the steel coils have been rolled into the requisite form, they are subsequently severed into individual rail lengths. The length of these rails may vary depending on the specifications of the railway track being produced. The rail lengths then undergo further processing to eliminate any flaws and straighten them out. Following this initial shaping and processing, the rails undergo a series of supplementary treatments. These treatments may entail heat treatment to bolster their strength and durability, as well as various surface treatments to prevent corrosion and wear. Once the rails have undergone all the necessary treatments, they are ready for installation on the railway track. They are laid out meticulously in a predetermined pattern, with each rail securely fastened to the sleepers or ties. The continuous length of steel provided by the coils ensures a seamless and uniform track, enabling trains to travel smoothly and safely. In conclusion, steel coils are crucial components in the production of railway tracks. They are utilized to manufacture the rails that serve as the foundation of the tracks, guaranteeing durability, strength, and a smooth surface for trains to traverse. The use of high-quality steel coils in this process is essential to ensure the safety and efficiency of railway transportation.

- Q: What are the typical coil width options?

- The typical coil width options vary depending on the industry and application, but common options range from 1 inch to 72 inches or more.

- Q: it isn't a SIGG water bottle or any other brand, as it's from thingsengraved what I'm wondering is, is this just as good as a SIGG water bottle, or is there any difference?

- Stainless steel is one of the best products to use for anything associated with food. It can be sterilized, it won't stain or absorb odors, it can be recycled and much of it is made of recycled material. If you take care of it, it can last a lifetime. We get hung up on brand names, you should look at the material it is made of. Which is a quality grade of stainless steel. I couldn't find the grade on the Sigg site, but I would think it would be the same or very similar. So, all that to say, this one seems to be as good as a Sigg.

- Q: What are the key factors affecting the strength of a steel coil?

- The key factors affecting the strength of a steel coil are the composition of the steel, the heat treatment process, the rolling and cooling processes, and the presence of any impurities or defects in the coil.

- Q: Can steel coils be coated with polymer?

- Yes, steel coils can be coated with polymer.

- Q: I just got my Daewoo K2 in 5.56 and i know they are tough and reliable but how well will it fair with steel rounds. I know shooting brass is better for any gun but what kind of extra wear and tear would i be looking at with shooting steel. Also what about reloading steel. Is it recomended. I would not even be asking this but steel is far cheaper than brass ammo, and i need to save some money.

- It would actually cost you more to reload steel.

- Q: How do we use steel ?plesase answer, its for homework xxx

- Strength of metals is normally measured by the tensile strength as the main measure although this is not the only property as hardness is another big factor. Basically, iron is soft and steel is hard. Plain iron is stretchy and does not corrode quickly, whereas steel is much stiffer and corrodes more quickly. The tensile strength of cold worked iron is about half that of an average steel, likewise the hardness is about half that of steel too. Pure iron, which is rarely used, is even weaker and softer again and a bit more like softer materials like copper and aluminium. Where confusion comes in is that there is another iron - Cast Iron - which is totally different to both iron and steel. Cast iron is very hard and tough but incredibly brittle so its properties are very different.

- Q: I have steel on my 9.5 ti now.. ive heard about synthetic being stronger but it snaps when it hits something sharp.. opinions people?

- I okorder

Send your message to us

JIS G3302 Hot Dipped Galvanized Steel Coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords