JIS & G/B Standard Steel Channel Module

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 40000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

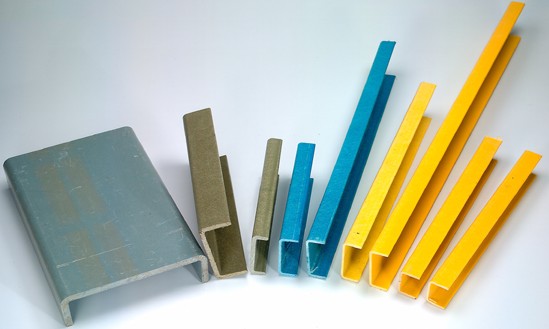

JIS & G/B Standard Steel Channel Module

OKorder is offering high quality JIS & G/B Standard Steel Channel Modules at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

JIS & G/B Standard Steel Channel Modules are ideal for structural applications and general fabricating.

Product Advantages:

OKorder's Steel Channel Modules are durable, strong, and resists corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (7-10 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

No. | Dimensions | Weight (Kg/m) | ||

Height (mm) | Width (mm) | Thickness (mm) | ||

5# | 50 | 37 | 4.5 | 5.438 |

6.3# | 63 | 40 | 4.8 | 6.634 |

8# | 80 | 43 | 5 | 8.045 |

10# | 100 | 48 | 5.3 | 10.007 |

12# | 120 | 53 | 5.5 | 12.059 |

14A# | 140 | 58 | 4.9 | 14.535 |

14B# | 140 | 60 | 8.0 | 16.733 |

16A# | 160 | 63 | 6.5 | 17.24 |

16B# | 160 | 65 | 8.5 | 19.752 |

18A# | 180 | 68 | 7.0 | 20.174 |

18B# | 180 | 70 | 9.0 | 23 |

20A# | 200 | 73 | 7.0 | 22.637 |

20B# | 200 | 75 | 9.0 | 22.777 |

22A# | 220 | 77 | 7.0 | 24.999 |

22B# | 220 | 79 | 9.0 | 28.453 |

25A# | 250 | 78 | 7.0 | 27.41 |

25B# | 250 | 80 | 9.0 | 31.335 |

28A# | 280 | 82 | 7.5 | 31.427 |

28B# | 280 | 84 | 9.5 | 35.823 |

30A# | 300 | 85 | 7.5 | 34.463 |

30B# | 300 | 87 | 9.5 | 39.173 |

32A# | 320 | 88 | 8 | 38.083 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: How do steel channels contribute to the stability of crane runways?

- Steel channels contribute to the stability of crane runways in several ways. Firstly, they provide a strong and rigid support structure for the crane to operate on. The channels are typically made from high-quality steel, which is known for its durability and load-bearing capacity. This ensures that the crane runway can withstand the heavy weight and dynamic loads imposed by the crane during its operation. Moreover, steel channels are designed to distribute the load evenly across the supporting beams or columns. This helps to prevent concentrated stress points and ensures that the load is spread out over a larger area, reducing the risk of structural failure or collapse. By distributing the load effectively, steel channels help to maintain the stability of the crane runway, even when subjected to heavy loads or sudden movements. Another important role of steel channels in crane runways is their ability to resist lateral forces. When a crane moves along the runway, there may be lateral forces generated due to wind, uneven loading, or sudden changes in direction. Steel channels provide a robust framework that can effectively resist these lateral forces, preventing any excessive deflection or sway in the runway structure. This is crucial for maintaining the stability and safety of the crane during its operation. Furthermore, steel channels can be easily fabricated and installed, allowing for efficient construction of crane runways. They can be customized to meet the specific requirements of the crane and the site, ensuring a precise fit and optimal performance. The versatility of steel channels also allows for various configurations and layouts, enabling the design of crane runways that can accommodate different crane sizes and load capacities. In summary, steel channels play a vital role in ensuring the stability of crane runways. Their strength, load-bearing capacity, and ability to distribute loads evenly contribute to the overall structural integrity of the runway. Additionally, their resistance to lateral forces and ease of installation make them an ideal choice for constructing reliable and safe crane runways.

- Q: What are the different connection methods for steel channels?

- Different connection methods are available for steel channels, depending on the desired structural integrity and application. Some commonly used methods include: 1. Welding: Steel channels can be connected by melting their edges and joining them together using heat. This method requires skilled welders and can be time-consuming, but it provides a strong and durable connection. 2. Bolting: Another common method is using bolts and nuts to secure the steel channels. This method is relatively quick and allows for disassembly if needed. However, it may not offer the same level of strength as welding. 3. Riveting: Heavy-duty applications often use riveting, where metal pins or rivets are used to join the steel channels. This method provides a strong and permanent connection but requires special tools and skilled labor. 4. Adhesive bonding: High-strength adhesives or epoxy can be used to bond steel channels together. This method offers a strong and flexible connection but may not be suitable for all applications and requires proper surface preparation and curing time. 5. Mechanical connectors: Mechanical connectors like beam hangers or brackets can also be employed to connect steel channels. These connectors provide a quick and easy method but may not offer the same level of structural integrity as other methods. When selecting a connection method for steel channels, it is crucial to consider factors such as load-bearing capacity, structural design requirements, and ease of installation. Consulting with a structural engineer or construction professional can help ensure the appropriate method is chosen for a specific project.

- Q: Can steel channels be used for pipe supports?

- Yes, steel channels can be used for pipe supports. Steel channels are often used in construction and engineering projects to provide structural support and stability. They can be effectively utilized as pipe supports due to their strength, durability, and ability to withstand heavy loads. Additionally, steel channels can be easily customized and fabricated to fit specific pipe sizes and configurations, making them a versatile choice for pipe support applications.

- Q: Are steel channels suitable for high-temperature applications?

- No, steel channels are not typically suitable for high-temperature applications as they can weaken and deform under prolonged exposure to high temperatures.

- Q: What are the different methods for reinforcing steel channels against bending?

- There are several methods for reinforcing steel channels against bending. 1. Adding additional steel plates: One method is to add steel plates to the top and bottom flanges of the channel. These plates are welded or bolted to the existing flanges, increasing their strength and stiffness. This method is commonly used when the channel is subjected to high bending forces or when it needs to carry heavier loads. 2. Using channel stiffeners: Channel stiffeners are additional steel members that are attached to the inside or outside of the channel to increase its strength and prevent bending. These stiffeners are typically welded or bolted to the flanges and web of the channel. They distribute the bending forces more evenly across the channel, reducing the likelihood of failure. 3. Reinforcing with concrete: Another method is to reinforce the steel channel with concrete. This is often done by encasing the channel in a concrete layer, which provides additional strength and stiffness. The concrete can be poured around the channel or precast and then attached to it. This method is commonly used in construction applications, such as bridges and buildings, where the channel needs to resist high bending forces. 4. Using composite materials: Composite materials, such as carbon fiber reinforced polymer (CFRP), can also be used to reinforce steel channels against bending. CFRP strips or sheets can be bonded to the channel's flanges or web, providing additional strength and stiffness. This method is lightweight and can be easily applied to existing structures or during fabrication. It is important to note that the choice of reinforcement method depends on various factors, including the magnitude of the bending forces, the type of application, and the available resources. Consulting with a structural engineer or a professional in the field is recommended to determine the most suitable method for a specific project.

- Q: What are the weight-bearing capacities of steel channels?

- The weight-bearing capacities of steel channels can vary depending on their dimensions, thickness, and quality of steel used. It is advisable to consult engineering manuals or consult with a structural engineer for specific weight-bearing capacities.

- Q: What is the weight of the national standard 8# channel steel?

- The theoretical weight of national standard 8# channel steel is 8.045 kg / m.

- Q: What are the different design codes for steel channels?

- There are several design codes that are commonly used for steel channels, including the American Institute of Steel Construction (AISC) Specification for Structural Steel Buildings, Eurocode, British Standards, and Canadian Standards. These codes provide guidelines and requirements for the design and construction of steel channels to ensure structural integrity and safety.

- Q: Can steel channels be used for column supports?

- Indeed, column supports can utilize steel channels. In construction, steel channels are frequently employed due to their robustness and longevity. They confer structural support and stabilize columns by evenly dispersing the load. By welding or bolting steel channels together, a sturdy and inflexible framework can be constructed for the columns. Furthermore, steel channels can be effortlessly tailored and trimmed to the desired length, rendering them suitable for a range of column support applications.

- Q: Can steel channels be used for HVAC duct supports?

- Yes, steel channels can be used for HVAC duct supports. Steel channels provide strong and durable support for the weight of HVAC ducts and can withstand the pressure and vibrations associated with HVAC systems. They are commonly used in commercial and industrial buildings for this purpose.

Send your message to us

JIS & G/B Standard Steel Channel Module

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 40000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords