Jinnuo Construction Hoist Motor

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1500 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Jinnuo Construction Hoist Motor

Product Details

Basic Info.

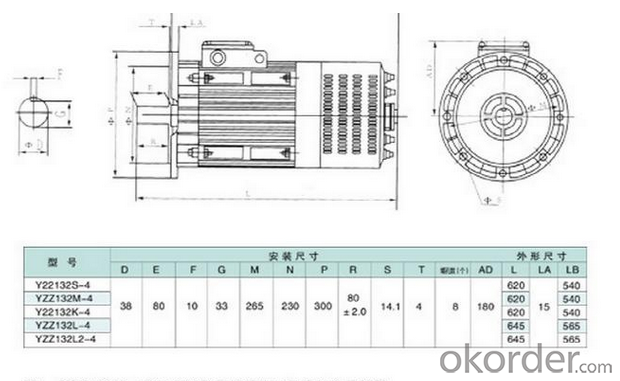

Model NO.:11KW 15KW 18KW

Type:Lifting Platform

Application:Construction Usage

Sling Type:Wire Rope

Power Source:Electric

Certification:ISO9001: 2000

Condition:New

Brand:Jinnuo

Export Markets:Global

Additional Info.

Packing:Wooden Case

Standard:SGS

Origin:Shanghai

Production Capacity:20000

Product Description

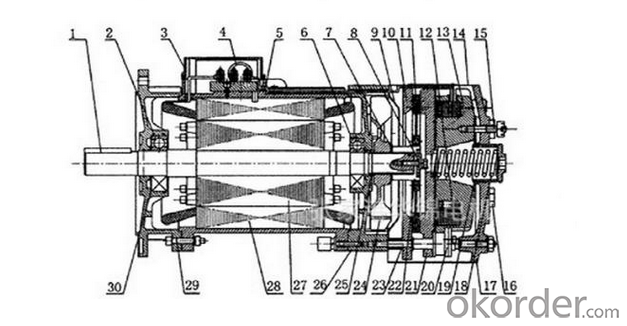

Appearance design: beautiful modelling concise;Brake wear hidden inside lead;Plug in type electromagnetic wire;Double rings seat design.

Internal performance: joint construction lifter actual working condition, internal reflect similar domestic leading level of the motor performance.

Embodied in: rated voltage 85% when can full load starting;Rated load 125% when relaxed starting and stable operation;Can be moderately happy to meet the demand of the brake adjustment;Frictionless operation of the brake disc structure to get higher running stability, low noise and high the whole life.

Reliability: the friction brake disc 12 months, the average life expectancy of armature and fixed brake disc life expectancy for 30 months, brake trouble-free working times, 200000 times on average, trouble-free working time is an average of 18 months;Motor can be selected embedded type thermal protection device, ensure reliable motor thermal overload protection.Interchangeability and maintainability: motor and DC brake

- Q: How does the PLC drive the stepper motor?

- General PLC drive stepper when two signals, one is angle pulse, another way is the direction of the pulse, PLC inside the so-called general displacement instructions, send trapezoidal pulse to a stepper drive, so you can start to bring the impact of buffer.

- Q: How to control the displacement and speed of the stepping motor?

- 2, the 28BYJ48 5V driver is KINGBOX supporting the 4 phase 5 wire stepper motor, and deceleration stepper motor.The speed reduction ratio is 1:64, and the stepping angle is 5.625/64 degrees. If you need to turn 1 circles, then you need360/5.625*64=4096 pulse signals.

- Q: Stepping motor chopper drive,Chopper constant current drive circuit is a better performance

- Chopper constant current drive circuit is one of the driving methods with better performance and more current use. The basic idea is that the current of the conduction phase winding is rated regardless of whether the motor is in the locked state or in low frequency or high frequency operation.

- Q: What are the main differences between a stepper motor and an ordinary motor?

- The difference between the stepper motor and general motors is mainly the driving pulse form (the control system sends out a pulse, you can make the motor rotate an angle), because of the characteristics of stepping motor and modern digital control technology combining (especially suitable for mechanical and electrical integration products). However, stepper motor in the control accuracy, speed range, low speed performance is not as good as the traditional closed-loop control of DC servo motor. The stepping motor can be used in the situation where the accuracy is not high, and the stepping motor can display the characteristics of simple structure, high reliability and low cost. When used properly, it can even compare favorably with the performance of DC servo motors.

- Q: What's the difference between a slow stepping motor and an ordinary stepper motor? Please answer, thank you

- The stepping motor is also stepping motor.The difference is that the reduction mechanism is fitted together inside the stepper motor, which looks like a stepper motor.The purpose is to adjust the speed and torque output.

- Q: I want to use single chip microcomputer (STC:89C52RC) control 42BYG positive inversion and speed, HSM20402 drive, how should I program?How can I set the pulse signal? What is the signal length and interval length?

- The motor operation needs to send a certain pulse to the drive, the pulse frequency to control speed

- Q: What is the maximum permissible temperature of the stepper motor?

- Fourth, the effect of feverAlthough the heating of the motor will not affect the life of the motor, it is not necessary for most customers to pay attention to it. But serious fever can have some negative effects. If the thermal expansion coefficient of each part of the motor is different, the change of the structural stress and the small change of the internal air gap will affect the dynamic response of the motor, and the high speed will easily step out of step. In some cases, excessive heating of the motor is not allowed, such as medical instruments and high-precision testing equipment. Therefore, the motor heating should be necessary control.

- Q: How to set the equivalent of stepper motor?

- 1, first of all know the lead screw, the pitch (lead) 5mm screw, that is, the distance between two filaments is 5mm;2, stepper motor is 1.8 degrees, 200 steps, go a circle is 200 * 1.8=360 degrees

- Q: What is the difference between switched reluctance motor and stepper motor?

- 2. The structure of the motor is simple, the rotor does not have any form of winding; the stator has only a simple central winding, the end is shorter, there is no inter phase cross wiring. Therefore, the utility model has the advantages of less manufacturing process, low cost, reliable work, small maintenance, etc..3, switch reluctance motor torque and current polarity not only need the current incentive way, the ideal public conversion circuit in each phase can use a switch element, and connected in series with the motor winding, not like the PWM inverter power supply, there is a risk of the two switches straight through. Therefore, the switched reluctance motor drive system has the advantages of simple SED circuit, high reliability and lower cost than the PWM AC speed regulation system.

- Q: Bought a linear stepper motor, the screw rod is through the end of the type. Bought to find that the screw has a significant shake. Now the use of lead screw found shaking badly. The seller said it is through type, all need to install a guide rail.I added a guide rail, may be the assembly accuracy of the rail is not high, the guide section of this bound, and the other end still shaking.Could you tell me how to solve this problem?

- Only in this way can you use the motor very well. If not concentric, will speed up the motor through the internal thread of wear, affecting the motor life. If you guarantee the concentric problem I mentioned above, the screw still wobbles. It may be that the screw itself is bent. You must straighten the screw rod at this point. You must find your electrical machine supplier to solve the problem.

Send your message to us

Jinnuo Construction Hoist Motor

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1500 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords