JCM936D Hydraulic Crawler Excavator

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

•JCM936D is a large bulldozer product. It adopts originally imported Cummins 6C8.3 engine which features Tier 2 standards, energy saving, environmental care, and convenient service and maintenance;

•It adopts radial seal air filter with pre-filter, large fuel pre-filter and coolant filter, which effectively prolongs engine life, with fuel filling pump and pressure transmitter as standard device for higher fuel economy.

•It adopts originally imported hydraulic parts, which features stable and reliable quality, and high efficiency, large digging force and travel force;

•It adopts new type cab and seats, brand-new interior, and new air conditioning system with automatic adjustment function for comfortable operation;

•New generation electric control system: large color display capable of real time monitoring of machine operation condition, self-diagnosis and recording, electric throttle, and multiple work modes.

•The enhanced working devices and undercarriage, and heavy duty chassis are applicable to tough work conditions;

•Multiple kinds of buckets and optional parts like dozer blades, breakers, scarifiers, electromagnetic suction cups, quick couplers, etc. are available for digging, landfill, breaking, and grading operations.

•The multifunctional GPS can achieve remote control and data transfer so that the real time machine conditions can be known.

•With symmetrically opened engine hood and exhaust pipe is installed at the hood, it is convenient for maintenance and services.

•Extra large tool case and fuel tank, centralized electric collocation;

•Box type frame side member, wide track gauge, long length on ground, with 600mm heavy track as standard device.-

JCM936D HydraulicCrawler Excavator

TechnicalSpecifications

Engine | Travel System | |||||||||||||

Model | CUMMINS 6C8.3 | Travel motors | Nabtesco, | |||||||||||

Type | Water cooling, turbocharged, empty enter-cooling | Support roller quantities | 2×8 | |||||||||||

Carrier roller quantities | 2×2 | |||||||||||||

No. of cylinder | 6 | Travel shoes | 2×49 | |||||||||||

Bore and stroke | 114mm×135mm | Travel speed | 2.95/5.04km/h | |||||||||||

Displacement | 8.3L | Drawbar pulling force | 284kN | |||||||||||

Power output | 186kW/2200rpm | Grade ability | 70% (35°) | |||||||||||

Ground clearance | 565mm | |||||||||||||

Hydraulic System | Cab & Control | |||||||||||||

Pump | FLUTEK, | Cab | All-weather, sound-suppressed Cab and equipped with a heavy, insulated Floor Mat; Front Window can be opened and slid; 6-direction adjustable Seat; LED display, Automatic monitoring, display and warning; cool & hot Air Conditioner | |||||||||||

Type | variable double–piston pump | |||||||||||||

Max. discharge flow | 2×265L/min | |||||||||||||

Max. discharge pressure | ||||||||||||||

Boom, arm and bucket | 32.5MPa | Control | Two hand levers and two foot pedals for travel Two hand levers for excavating and swing; Electric rotary-type engine throttle | |||||||||||

Travel circuit | 32.5MPa | |||||||||||||

Swing circuit | 27.5MPa | |||||||||||||

Control circuit | 3.9MPa | Boom, Arm & Bucket | ||||||||||||

Pilot control pump | Gear type | Boom cylinder | 140mm×100mm×1480mm | |||||||||||

Main control valve | Negative flow control | Arm cylinder | 160mm×110mm×1825mm | |||||||||||

Oil cooler | Air cooled type | Bucket cylinder | 150mm×105mm×1250mm | |||||||||||

Swing System | Refilling Capacities&lubrications | |||||||||||||

Swing motor | SUNJIN, | Fuel tank | 600L | |||||||||||

Swing motor type | Axial-piston motor | Cooling system | 25L | |||||||||||

Brake | Hydraulic oil released | Engine oil | 20L | |||||||||||

Parking brake | Hydraulic disc brake | Hydraulic oil tank | 375L Tank oil level | |||||||||||

Swing speed | 10.5r/min | 500L Hydraulic system | ||||||||||||

Bucket | ||||||||||||||

Type | Backhoe bucket | |||||||||||||

Bucket capacity | 1.6m3 (SAE) | |||||||||||||

Bucket width | 1551mm | |||||||||||||

Arm Type |

| |||||||||||||

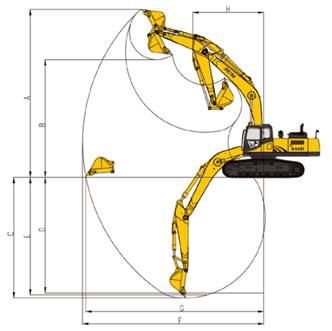

A | Max. digging depth | 10164mm | ||||||||||||

B | Max. dumping height | 7121mm | ||||||||||||

C | Max. digging height | 7301mm | ||||||||||||

D | Max. vertical digging depth | 7000mm | ||||||||||||

E | Max. Depth cut for 2440m(8')Level Bottom | 7121mm | ||||||||||||

F | Max. digging distance | 11084mm | ||||||||||||

G | Max. digging radius at ground level | 10886mm | ||||||||||||

H | Min. swing radius of work equipment | 4335mm | ||||||||||||

Digging Force (ISO6015) Unit: kN | ||||||||||||||

Arm length | 3186mm | |||||||||||||

Bucket digging force | 207.5kN | |||||||||||||

Arm digging force | 154.4kN | |||||||||||||

Arm Type 3186mm | ||||||||||||||

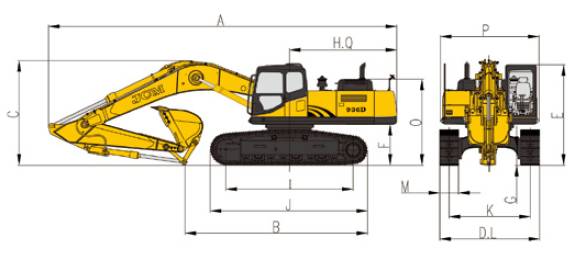

A | Overall length | 11161mm | I | Tread | 4080mm | |||||||||

B | Ground contact length (Transportation) | 5856mm | J | Track length | 5044mm | |||||||||

C | Overall height(to top of boom) | 3347mm | K | Track gauge | 2600mm | |||||||||

D | Overall width | 3200mm | L | Track width | 3200mm | |||||||||

E | Overall height(to top of cab) | 3211mm | M | Shoe width | 600mm | |||||||||

F | Counter weight ground clearance | 1310mm | O | Bonnet height | 2752mm | |||||||||

G | Ground clearance | 565mm | P | Revolving frame width | 3165mm | |||||||||

H | Tail swing radius | 3438mm | Q | Distance from swivel center to tail | 3438mm | |||||||||

| ||||||||||||||

Operating Weight and Ground Pressure | ||||||||||||||

Operating weight includes basic machine (with boom 6.47m, arm 3.186m, and bucket 1.6m3) | ||||||||||||||

Shoe width | 600mm | |||||||||||||

Overall width | 3200mm | |||||||||||||

Ground pressure | 66.2KPa | |||||||||||||

Operating weight | 35700kg | |||||||||||||

- Q: I am currently studying Anthropology, and someone told me that I could only dig in archeological sites if I had a BA in Archeology. I'm not sure if that is real or not.

- Huh? Plenty of people without degrees in anything have worked as supervised excavators and technicians on Archaeology digs. In fact, through organizations like Earthwatch or Crow Canyon, complete amateurs can pay to participate in field digs. So I'm not clear on what this person meant -- perhaps they misunderstood and thought you were asking if you could head up a dig yourself. In fact, at the University I attended Archaeology was considered a sub-field of Anthropology and you had to get your degree in Anthro even if you took the full curriculum for Archaeology. If you were intending to work on a field dig they would certainly prefer that you had taken courses that taught field techniques and standards so that you understood what needed to be done. Most Chief Investigators (who are directly responsible for the field operations and daily oversight) have PhD's in Archaeology. Even with a PhD you can't just go out and start digging anywhere you wish. There are protocols to be followed.

- Q: Modern 305-7 excavator oil consumption per hour, how many liters oil full load?

- Modern 305-7 excavator oil consumption 0.2 liters / horsepower * hour full load.Excavator, also called excavating machinery, is a kind of earthmoving machine that uses bucket to excavate material that is higher than or lower than the machine surface and is loaded into transportation vehicle or unloaded to the stacker. Excavators are mainly made of soil, coal, sediment, and soil and rocks that have been pre - loosened.

- Q: How much would it cost to rent a excavator for pulling up stumps per day ? On average

- We get 100 an hour for a wheel hoe and 2 hundred an hour for the track hoe. including an operator If the operator is knowledgable you can dig a lot of stumps in an hour.

- Q: I am doing a paper and I would like to know because I can't find hardly anything on the internet..Sources too if you give an answer.Thank you in advance!

- pharoes acient egypt tattoos represent thier royalty

- Q: Any help would be greatly appreciated........The Deutz f4m1008 engine on my mini-excavator will start fine and it will run for about 5-10 minutes and then starts sputtering for 15 - 20 seconds or so and then it konks out. I can restart it again, after a few minutes. Then, after a shorter 2 minutes of running, it konks out again. I can do this ten times in a row if I wanted to and it does the same thing, run 2 minutes then quit. The fuel cap was removed to check if it was a vaccuum problem and that didn't help. There are no fuel line obstructions. I replaced the fuel filter and found that one of the stems on the fuel pump (I assume it is the pump on top of engine) was loose. I was happy thinking that I had found the problem, but no such luck. Anyways, the radiator is full, as is the oil. I added additional conditioner as well as anti-freeze in case of moisture. I am wondering if the solenoid for the fuel cut-off is malfunctioning.Thank you in advance for any help.

- Tank screen or air in lines.You can have bad diesel(water in fuel).

- Q: Who can offer used excavators for specific information?

- For more information on excavators, more excavator supplier information

- Q: Kobelco excavator computer alarm P0405 is what mean?

- P0405 is the EGR valve alarmGive the best song!

- Q: What porn people 3000 years back must be using when forget about audio / visual recording , even printing technology was either too primitive or non existent ? Or people in those days did not see a requirement for porn ?

- 3000 years ago, people used to use erotic paintings... Yes due to the Internet, porn has become easily available... Nowadays people use sexual connotation in most of the things such as comedy, movies, even conversations...

- Q: What is the length, width and height of bucket shovels for type 240 excavators?

- PC240 excavator bucket capacity is fand 1.2m. PC240 excavator is optional: light work: 1.17m bucket bucket fand width: 1295MM; 1.26m: 1391MM; fand width narrow heavy work bucket: 1.3m width: 1132MM fand.Excavator bucket capacity expansion:Model is 35, that is, 3.5 ton bucket capacity of about 0.11 cubic meters;

- Q: Me and my husband are starting a equipment rental business (like bobcats, excavators, trenchers). We are trying to come up with a business name that sounds professional. Our last name is neal and we were thinking about incorporating that but would also like some other ideas. please help!!! thanks

- Please edit your posting. Include your last name, the area you are in (State, County, Town, and any nickname of the above). Is your area historic for any reason? Is there a river nearby or other point of interest? Let us have more to go on. For example, in Lyons County there is the High Desert tourist area. If you were there, I could recommend LHD: Long, Hard, and Deep. Actually, for more professionalism, I would take Lyons High Desert and come up with other things that have the initials of LHD. But you have the idea now.

Send your message to us

JCM936D Hydraulic Crawler Excavator

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords