Interior Wall Paneling Spectra Aluminum Composite Panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

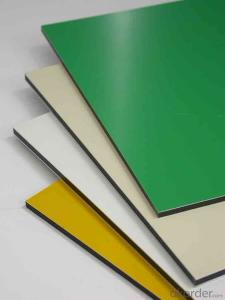

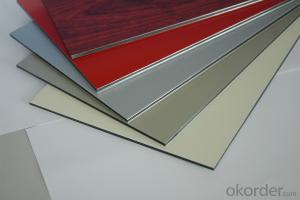

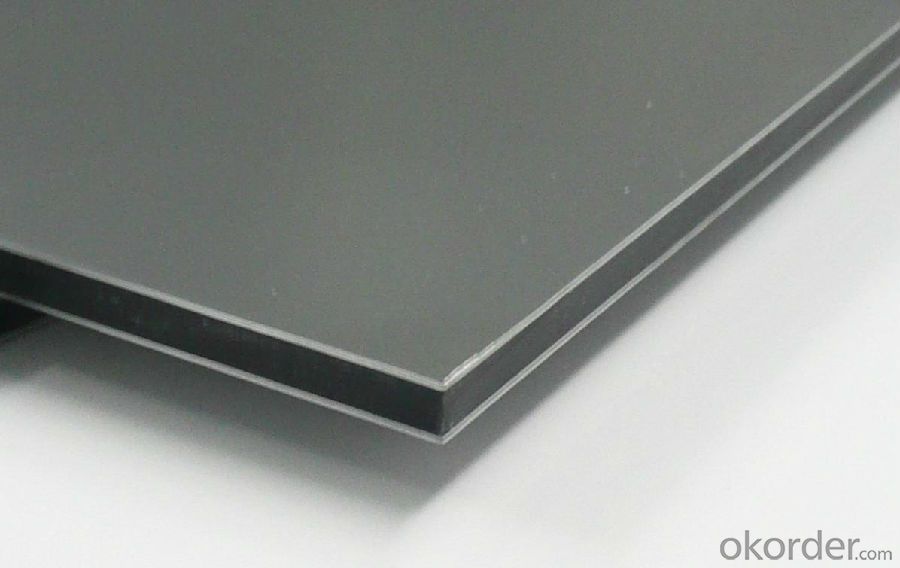

Interior Wall Paneling Spectra Aluminum Composite Panel

1. Standard:

according to GB/T 17748-1999 standard

2. Material:

a) Front: aluminum alloy sheet coated with fluoro-carbon resin

(PVDF) and polyester resin (PE) roasting painting

b) Core: nontoxic polyethylene.

c) Back: aluminum alloy sheet coated with polyester resin painting

d) Surface finish: treated with PVDF and PE resin rolling roasting .

coating

e) Surface coating thickness: 30um

f ) Aluminum alloy sheet thickness: 0.1mm, 0.12mm, 0.15mm, 0.2mm,

0.3mm, 0.4mm, 0.45mm, 0.5mm

3. Dimensions:

a) Thickness: 3mm, 4mm

b) Width: 1220mm 1500mm..

c) Length: 2440mm, 3200mm, 4000mm,5000mm (max: 6 meter)

d) Weight: 5.5kg/sqm based on 4mm thickness.

e) Standard size: 1220 x 2440mm

f) Nonstandard sizes are available according to requirement of customers

4. Application scope:

1) Building exterior curtain walls..

2) Decoration and renovation additions for old buildings

3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies

4) Shop door decorations

5) Advertisement board display platforms and signboards

6) Wallboards and ceilings for tunnels..

7) Industrial materials, materials for vehicles and boats

Production Machinery:

| Machine Name | Brand & Model No. | Quantity | Number of Year(s) Used | Condition |

|---|---|---|---|---|

| Coating line | WANGUAN | 2 | 4.5 | Acceptable |

| Aluminum plastic composite line | FB1600 | 4 | 3.5 | Acceptable |

| Embossing line | No information | 1 | 1.0 | Acceptable |

Testing Machinery:

| Machine Name | Brand & Model No. | Quantity | Number of Year(s) Used | Condition |

|---|---|---|---|---|

| Bending machine | No information | 1 | 8.0 | Acceptable |

| Visual comparison of the colour device | MSBS-1 | 1 | 5.0 | Acceptable |

| Drying oven | PULUO | 1 | 5.0 | Acceptable |

- Q: Bedroom room tide, often out of the wall, just finished a year began to fall out, and then also out of the decoration, wallpaper stickers also up, the basic wall can not get anything, want to use the plate to the wet wall separated, Can I use aluminum or aluminum gusset? Or other plates? Which is more suitable for the bedroom, and is a large area

- You can use aluminum-plastic panels, but if you want to look better than the space, aluminum-plastic plate inside to play keel to do, the effect is good, rich color cut easily shape, you want to brush the paint inside the wall to shovel and then brush strong.

- Q: Aluminum-plastic plate and color steel tile which is more durable

- Aluminum-plastic panels are more durable.

- Q: 3MM aluminum composite panel prices

- The same structure of the 3 mm thick aluminum-plastic plate, according to different manufacturers and origin, the price is also very different, such as the production of Guangdong and Shandong production, Jiangsu and Zhejiang area production, the price difference is large, is the same product produced in Guangzhou, Then for 3 mm 0.12 mm aluminum thick product, the price is 80-180 yuan / Zhang between the bar.

- Q: Can the aluminum plate absorb the magnet

- Of course not, but what do you want to do with it? Is the aluminum-plastic plate to do a good job with the magnet stickers put on the metal support or aluminum-plastic plate wall suction other, is not afraid to use double-sided adhesive temporarily removed when there are traces of ah, you can buy 3m double Surface tape, can not afford to glue, you can use many times is your point, in short, first said that the use of friends, give you think of a way

- Q: The ceiling is the singing of the aluminum plate with vibrating sound how to do it

- If invalid, it is recommended to replace the thickness of the aluminum plate

- Q: The cost of accessories if the square, then how much money a square ah

- There are manufacturers reported 105 yuan / square meters are about.

- Q: These two kinds of longer life with the customer? The The

- Do the material of the door if the life is not as good as you can get how much money to do aluminum-plastic board FC can guarantee 10 years if the color of the polyester deep time can not guarantee too long if the light can guarantee 3 to 5 years

- Q: My family in Foshan Chancheng, home kitchen ceiling to change! Do not know the aluminum plate is good, or aluminum-plastic plate is good? How much are their prices and materials?

- Personal personal advice you do aluminum plate, because the aluminum plate is to use glue attached to the plywood, which is related to the quality of the glue, followed by the paste technology is also related to the three also with the splint of the ups and downs, and finally Ask you still ready to replace it? If sure, that aluminum plate will not bring you trouble, if not change, it is still aluminum plate, the time is better. The price of a business can be imagined

- Q: OKorder Huayuan Fluorocarbon aluminum plate aluminum thickness 50mm each price is how much? Best to have pictures!

- Not so thick aluminum plate, there is no such a thick aluminum plate it.

- Q: On the Kyrgyzstan and auspicious brand of aluminum plastic plate which is good

- Oh, do not want to talk about, aluminum or white plate or choose the day of aluminum it. The The

Send your message to us

Interior Wall Paneling Spectra Aluminum Composite Panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords