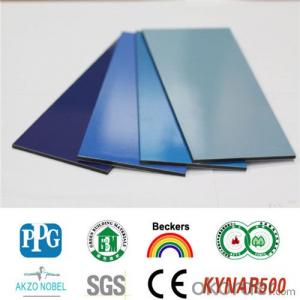

Exterior and Interior Aluminum Composite Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Exterior and Interior Aluminum Composite Panel

Product Description

| Name | Exterior and Interior Aluminum Composite Panel | |

| PVDF | 4*0.4mm | Most Popular In The World For Outdoor Decoration |

| 4*0.5mm | Best For Outdoor Decoration In General | |

| 4*0.3mm | Economy Also Meet Requirement For Outdoor Decoration | |

| 3*0.3mm | Popular For Indoor Decoration In Commercial Building | |

| 4*0.5mm | Superior Fireproof Performance On The Basis Of The Best Specification | |

| Fireproof | ||

| PE | 3*0.3mm | Most Popular In The World For Indoor Decoration |

| 3*0.21mm | Economy For Indoor Decoration In General | |

Constitution Structure:

1) Top Coating Polyester

2) Aluminum skin

3) Macromolecular lamination film

4) Nontoxic polyethylene core or No-combustible filled core

5) Macromolecular lamination film

6) Aluminum skin

7) Service coating or mill finished

Characteristic:

| Characteristic | Detailed explanation for each point |

| More color options | IDEABOND polyester coating ACP is with extremely vivid & offering thousands color options. |

| Smooth Surface | IDEABOND Polyester Aluminium Composite Panel provides superior and smooth surface, satisfying the modern building with perfect appearance. |

| High Strength | IDEABOND Polyester Aluminium Composite Panel with the high quality polyethylene core which can be greatly enhanced strength ensures the performance of wind-pressure resistance, shockproof, and anti-impact. |

| Easy Processing | ACP is easy to cut, slot, punch, bend into circular, rectangular and other shapes also can be designed to various modeling according to your ideas. |

| Environmentally Friendly | IDEABOND PE ACP is green building decorative material; Can be easily processed and installed; Light weight, good strength and flexibility |

| Economic | IDEABOND PE ACP is more economic than many other materials like ceramic, aluminium single panel, or real stone etc. |

Specification:

| Item | Total Thickness(mm) | AL thickness(mm) | Width(mm) | Length(mm) |

| Standard | 3, 4 | 0.21, 0.3 | 1220 | 2440 |

| Option | 1, 2, 5, 6 | 0.12~0.5 | 900 ≤ W ≤ 1600 | Customized |

Profermance:

| Dimensional Tolerances | Thickness(mm) | ± 0.2 |

| Width(mm) | ± 2 | |

| Length(mm) | ± 3 | |

| Diagonal(mm) | ± 5 | |

| Thermal Expansion | 2.4mm/m at 100 º C temp difference | |

| Aluminum Thickness(mm) | ± 0.02 | |

| Surface Properties | Pencil Hardness | > HB/> 2H |

| Temperature Resistance | -50 º C to +80 º C | |

| Impact strength (kg. cm) | 50 | |

| Boiling Resistance | Boiling for 2 hours without change | |

| Acid Resistance | Immerse Surface in 2% HC1 for 48 hours without change | |

| Alkali Resistance | Immerse Surface in 2% NAOH for 48 hours without change | |

| Oil Resistance | Immerse Surface in 20# engine oil for 48 hours without change | |

| Solvent Resistance | Cleaned 100 times with dimethylbezene without change | |

| Cleaning Resistance | Over 1000 times without change | |

| Peel Strength 180 º C | 180oC> 5 newton/mm | |

| Product Properties | Sound Absorption NRC | 0.05 |

| Sound Attenuation RW db | 23/24/25 | |

| Water Absorption % by volume | 0.0047/0.0057/0.0012 | |

| Core Composition | LDPE Polyethylene, Non- Combustible Material |

Package:

Applications:

1) Building exterior curtain walls

2) Decoration and renovation additions for old buildings

3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies

4) Shop door decoration

5) Advertisement board display platforms and signboards

6) Wallboards and ceilings for tunnels

7) Industrial materials and materials for vehicles and boats

FAQ

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons

Q: What are your payment terms?

A: We accept L/C, D/A, D/P, T/T, West Union, etc

- Q: What silk screen paint is suitable for printing aluminum

- Fluorocarbon resin, polyester resin Suitable for high temperature dry paint are suitable for printing aluminum.

- Q: China, how can sell aluminum plastic plate, it is best to have a number of stores can be compared, the thickness is about 2-3MM, the price in general how much? Advertising light box

- If you do light boxes, you can purchase some of the 150 or so has been enough to use. 2 mm board material should be priced at around 100 yuan, too cheap also, but the quality has not guaranteed the basic needs.

- Q: OKorder side there is no production of new materials, aluminum-plastic plate manufacturers? I want to use the pillars, the need to process the arc, very anxious to solve!

- I am not in OKorder in Kunming, do not know useful to you! The last time I do in Liupanshui do gas station is also need to pack pillars, Party is also required to use new materials, aluminum-plastic plate, I find a long time did not find, and later from Kunming cloud like building materials, anyway, OKorder is not here from us Far, useful words remember to adopt! Thank you

- Q: I am not on the aluminum construction, would like to know the door of the aluminum-plastic plate construction and external construction, I hope you have educated us, first thank you

- Dry hanging: the same bottom hit metal shelves. Save the big core board. Directly in the aluminum-plastic plate surface planing slot with a rivet fixed. But dry hanging aluminum plate price is high. Weatherability is not as good as the above

- Q: OKorder Jixiang Technology Group production and sales of aluminum-plastic panels and aluminum veneer, but also what products?

- In addition to aluminum-plastic panels and aluminum veneer, but also operating aluminum-plastic panels and aluminum veneer.

- Q: Chengdu sales of aluminum-plastic plate, aluminum veneer, aluminum dealers

- Chengdu Xing Jimei curtain wall materials Co., Ltd. mainly sell aluminum, aluminum-plastic plate, aluminum veneer (the company has a number of agents such as Guangzhou Gold and well-known brands)

- Q: 3d board and aluminum plate prices? What kind of price?

- This is to sub-material, generally relatively high prices of aluminum-plastic plate

- Q: It is good for aluminum manufacturers of aluminum alloy cans

- Do you need aluminum or aluminum cans?

- Q: The market for aluminum-plastic plate processing machines so much, which brand is good?

- I know this problem, I'll tell you about it ~ This style is a lot of the price is different, mainly to see the quality, it is recommended that you go to the market to see, choose a few more, to be a comparison. I recommend the United States of America Maidike Mulitcam large CNC aluminum-plastic plate processing center for a variety of thick / thin aluminum, aluminum-plastic panels, aluminum curtain wall, aluminum honeycomb board, aviation yacht with aluminum cutting, drilling, modification and other processing, Kind of processing features hope to help you! Have a reference to you

- Q: What is the difference between aluminum and aluminum curtain wall aluminum veneer? That cost is high!

- Composite aluminum plate, also known as aluminum-plastic plate: aluminum - plastic - aluminum three layers, aluminum veneer for the composition of aluminum, aluminum veneer than the high

Send your message to us

Exterior and Interior Aluminum Composite Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords