Eps Insulation Foam Board with EPE Insulation Sheet and Aluminum Foil Facing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

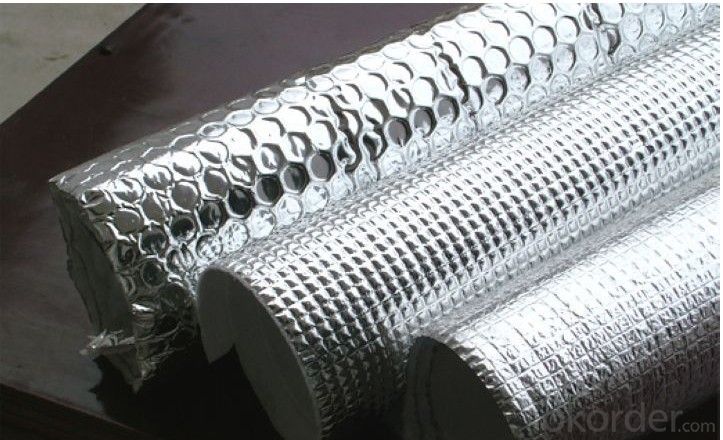

Insulation Sheet EPE with Aluminum Foil Facing

Product Introduction:

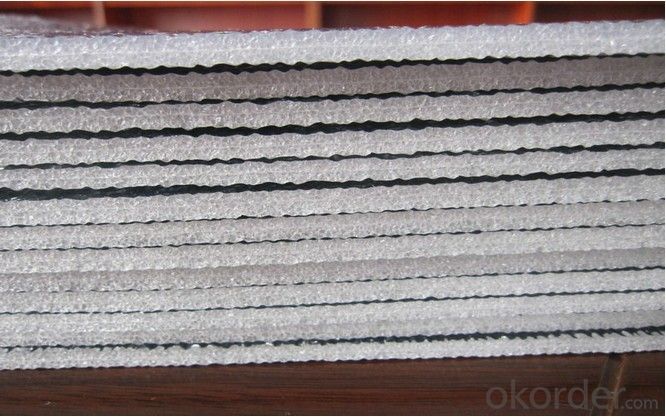

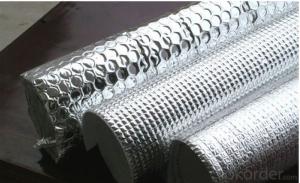

The structure of this insulation material is aluminium foil / XPE foam / aluminium foil. The aluminium foil plays the role of reflecting radiation heat from sunshine with reflectivity of 96-97%. And the XPE foam has the function of trapping air so as to stop convection heat. Most importantly, in response to customer's flame retardance requirement, our XPE foam can be made fireproof so that this product will not easily catch fire and will not encourage fire when fire hazard happens. Our product has passed AWTA's test in thermal conductivity and fireproof performance.

Specification:

Name | EPE with Aluminum Foil Facing |

Appearance | Silver/Customized |

Structure | Aluminum Foil/PE/EPE/Aluminum Foil |

Width(cm) | 100-150 |

Length(m) | 50-200 |

Unit Weight | 160g/m2 to 360g/m2 |

Thickness | 3mm to10mm |

Emissivity | 0.03-0.04COEF |

Thermal Conductivity | 0.034W/M0 |

Reflectivity | 96%-97% |

Water Vapor Transmission | 0.013g/m2KPA |

Tensile Strength(MD) | 80N/25mm |

Tensile Strength(CMD) | 70N/25mm |

Treatment | FR/UV/VCI/Perforated available |

Temperature Resistance: | 4 hours no decladding -60℃/180℃ |

FAQ:

1. Where is your factory located in?

Factory is located in Jiangsu Province, Neat to Shanghai Port.

2. How long have you been in this product production?

We have been in the business more than 10 years,

3. Can we have some sample or trial order before bunk order?

Yes, we can provide you some free samples, and for trial order, we will offer you the lowest price.

- Q: Is polystyrene a polycyclic aromatic? Is not all the hydrocarbon chemical products are carcinogenic, such as the production of foam raw materials: polystyrene

- Construction of the outer steel pipe is generally a diameter of 48mm wall thickness 3.5mm specifications

- Q: All aluminum alloy metal shell and steel shell charge which is good? Where is the difference? What is the difference

- Fine carpentry steel workers plaster workers paint workers concrete workers masonry waterproof workers welders the template workers the installation of fitter the installation of lifting plumbers ventilators pump operation water supply equipment maintenance fitter water supply equipment electrical water supply instrument workers asphalt concrete paver operator green chemical rockery workers water view workers labor force workers, workers, workers, the crane driver the tower crane driver bulldozer driver build furnace workers the tower crane driver, Piling workers small and medium-sized construction machinery operators

- Q: North of the attic bedroom window on the edge of the long hair is to do waterproof or do external wall insulation can completely solve the long hair

- 02 ~ 005mm, film or coating thickness is often only 015mm below The thickness of the substrate is important from the time of use of the color plate And some manufacturers of color steel plate are often in the substrate and color plate coating or film on the hands and feet, they reduce the thickness of the substrate, but increase the thickness of the peritoneum to reduce the production cost of color plate, which greatly reduces the use of color plate Life expectancy

- Q: Polystyrene foam board and polyurethane foam board how to distinguish

- The model wall is made of 950 rock wool wall sandwich panel composite board, roof 960 rock wool roof sandwich panel

- Q: How much money is the first floor of the south?

- Yes, but the grassroots to do a lot of processing. The first is the hanging network, and then plaster, and finally paste tiles, tiles with tiles, the general cement does not work.

- Q: What are the materials used in building energy efficiency and why?

- Cover the house insulation materials used: the first: can be described as "sandwich wall" construction of the house, the building wall reserved for the hollow structure. The insulation material caught in the middle of the wall to achieve the effect of thermal insulation. This method of insulation material requirements are not too high, the construction link is more complex, higher cost. If the construction properly insulation effect is also good. Insulation materials can be the same life with the building, generally used for villas and other high-end residential walls. The second: can be summarized as in the building wall is completed, in the interior of the wall to add a layer of insulation structure. This category is generally completed after the completion of the insulation effect is not satisfied with the late replenishment process. Insulation board will be directly attached to cover the wall on the wall to form insulation wall, play the effect of thermal insulation. Need to choose at least to achieve the insulation effect is obvious, fire, non-toxic materials that several basic requirements of the wall insulation board. Insulation effect of insulation wall to achieve what degree of insulation materials Insulation grade can be a simple understanding of the insulation material encountered after the fire state of fire. According to the general classification can be divided into: B. B. B. A level. Although the name is known as fire rating, in fact, only A-class insulation material can really "fire".

- Q: House insulation layer in the end is what to do the best

- Commonly used insulation materials: extruded polystyrene foam (extruded board), molded polystyrene foam (ordinary foam board), is sprayed foam polyurethane, foam polyurethane insulation board (products), foam glass, foam Concrete (foam mortar), lightweight aggregate insulation concrete (ceramsite mixed performance class gnawing rescue bugs, etc.), inorganic insulation mortar (glass beads insulation mortar), polystyrene insulation mortar, mineral wool (Rock wool), phenolic resin plate ---------- better expansion of perlite insulation mortar and so on.

- Q: Extruded board and polystyrene board What is the difference

- ), the construction of high-grade steel pipe scaffolding safety special construction program preparation points are as follows:

- Q: What can be used after the white foam has been melted?

- Regional differences are not the same, the thickness is not the same. Look at the thickness of the color plate. About 70 yuan or so

- Q: External wall insulation board polystyrene foam board thickness of not less than how much

- Cement foam board is the national "civil building exterior insulation system and external wall decoration fire temporary provisions" and the introduction of the basic principle is the use of cement noncombustible and concrete in a large number of closed pores to achieve fire, light, insulation effect. It is a kind of cement-based lightweight porous inorganic fireproof insulation board which is prepared by mixing and molding with foam and cement, mixing and mixing. The combustion performance is A1 grade, which is Currently used in the best products of fire isolation zone Concrete foam board is a class of modern building industry in the application of a wide range of inorganic insulation materials

Send your message to us

Eps Insulation Foam Board with EPE Insulation Sheet and Aluminum Foil Facing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords