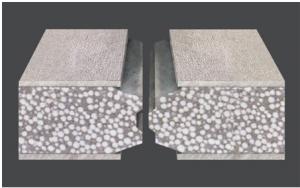

Calcium Silicate Board Siding Plank with EPS Rigid Foam Board Insulation

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Square Meters m²

- Supply Capability:

- 100000 Square Meters per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

-calcium silicate board

-fiber reinforced cement board

-waterproof

-fireproof

-ideal ceiling and wall partition material

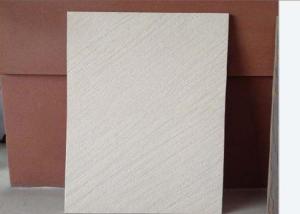

It is a kind of calcium silicate board with cedar pattern , medium density and low water absorption .The purpose of Siding plank is for climate-resistance, waterproof, wind loading resistance, UV proof, exterior wall leaking protection and good thermal insulation. It can be used for exterior wall cladding and façade of various high-class and high rise civil building which demand in artistic effect.

1. Durable.

More than 60% of the composition is same as granite, more than 20% same as marble.

2. High strength.

The lowest strength (in parallel direction) is ≥14Mpa while the highest strength ( in cross direction) is ≥16Mpa which meets the national standard of typhoon-resistance.

3. Light weight and low water absorption.

Then density is ≥1.25 g/cm3. The water absorption is less than 35%. It can be used in new buildings for there will be no need to take additional load for them. Its light weight settles the problems of the renovation in the facade of old buliging and the leaking from the facade. It won’t affect its original construction.

4. Incombustible material.

Meet the standard of GB 8624- 1997 grade A and ISO-1182 which is the guarantee of the fire proof.

5. Good at impact resistance.

It can be used as the base board in the shops, hotels, schools, entertainment places and hospitals.

6. Outstanding thermal insulation and keeping warm capability.

Siding plank has the capability in aeration, balancing the wind pressure, keeping the function of the system with warmth and thermal insulation, making the loss and expense of air-conditioner and warm gas in the building decreased.

7. Low moisture and water absorbing.

It can be used in outdoor wet area.

8. Inorganic material.

It’s fireproof, anti fungus and mould proof are good for the user’s health.

10. Good quality and competitive price.

Compared to other boards (real non-asbestos calcium silicate board) from international marker, it is much worthy.

Specification

Thickness |

Width |

Length |

mm | ||

7.5,9 |

241,192 |

3050 |

Remark: we can also supply other specifications as the client’s special requirement. | ||

Physical properties

Item |

Index |

Unit | ||

Density |

≥1.25 |

g/cm³ | ||

Thermal conductivity |

≤0.3 |

W/(m·k) | ||

Water absorption |

≤38 |

% | ||

Water contain |

≤10 |

% | ||

Moisture movement |

≤0.25 |

% | ||

Anti-freezing |

No cracking or delaminating |

25 times of freeze-thaw cycles | ||

Non-water soaking |

No Water Forms after being tested |

24h 24 hours | ||

Incombustibility |

GB 8624-2006A1 |

/ | ||

Bending strength |

Oven dry |

Parallel |

≥16.0 |

Mpa |

Cross |

≥11.0 |

Mpa | ||

Full water condition |

Parallel |

≥10.0 |

Mpa | |

Cross |

≥7.0 |

Mpa | ||

Impact resistance |

Oven dry |

No continuous cracking after one impact |

/ | |

Remark; please contact our technical department if you need more technical index. | ||||

Safety capability

Item |

Index |

Instruction |

Asbestos contain |

100% asbestos free |

Safe for application |

Radioactivity |

<1.0IRa |

Safe for application |

<1.0Ir |

Safe for application | |

Incombustibility |

A1 |

The highest grade |

- Q: Common electrical packaging white foam can do insulation materials

- Good plastic, and aluminum compared to the strength of considerable toughness better, which you say good? The The

- Q: What is the meaning of EPS in insulation materials?

- Hey hey Tonight because of work needs, to sort out this information, by the way to answer your question, may not be very full, but at least from the performance side (in fact there are life and corrosion resistance, sealing and maintenance aspects, hydraulic characteristics, transport Installation and construction, etc

- Q: Insulation board and holding plastic from the chemical reaction? Insulation board dip in the glass, with the structure of plastic line

- Both are made of polystyrene as the basic raw material for processing, but due to the different processing technology, the formation of two different insulation materials

- Q: Cold storage installation commonly used in insulation materials can be divided into what

- Temporary electricity, scaffolding, foundation pit support, templates, tower crane, material hoist, material Taiwan, lifting, demolition, blasting, winter rain season.

- Q: Xps insulation board and extruded board which is good

- Landing scaffolding to build acceptance records Table 3-6-7 Project name: Engineering unit name: Urban construction company No. Acceptance project erection requirements test results 1 pole base solid level, there are drainage measures. Diverage 5cm thick plank, erected high > 7.55 m, 2 frame and pull knot joint spacing, horizontal, vertical distance to meet the requirements, pull the material meet the requirements, height> 12.6 meters are not allowed to use flexible connection 3 construction layer springboard double springboard banding point of not less than 4 points 4 scissors set not more than 9m set a scissors, angle of 45 ° ~ 60 °, from bottom to top continuous set, the height of more than 24m, in the foot of the corner and the middle along the vertical every 60 ° across the horizontal plane erected Slanting 5 scaffolding material scaffolding fastener steel pipe foot pipe diameter shall not be less than Φ48mm, wall thickness shall not be less than 3.5mm, no serious corrosion, crack, deformation, fastening torque 45 ~ 50N · m6 scaffolding width by design width 1) m erection 7 pole spacing vertical deviation of the vertical bar is not greater than the full length of 1 / 100H, vertical distance between the vertical design (1.8m) m set, deviation ± 50mm8 size horizontal horizontal horizontal vertical.

- Q: Open to move the planting of the state of the country to pay taxes Bao Jing home balcony built a very small wall, which posted the brick, the external walls of cement mortar smoothed now want to brush waterproof and latex paint, how should I do . brush Exterior wall waterproof, putty, exterior latex paint . direct brush external wall paint I do not understand, but the area is very small, I want to get more

- I do not know what the problem you said is not clear, to send the following to you, for your reference: [Case 1] a single industrial plant project, eaves high 20m, construction area of ??5800m2

- Q: Air conditioning duct glass wool insulation loss is how much

- Once the natural gas leak will cause an explosion, fire and so on

- Q: Building exterior wall insulation board fixed bolt specification how much distance one

- Construction site tower crane (tower crane) lightning protection grounding resistance should not be greater than 4Ω

- Q: What can be used after the white foam has been melted?

- Can be, one is 30 * 50 wood with plastic expansion screws fixed on the wall, spacing 400-. and then nail gypsum board. The other is the smooth muscle pull can be Ji Jiu help snow burst grinding wall leveling leveling, and then directly to the gypsum board nail wall.

- Q: What building materials to build a house insulation effect is better?

- The division of labor in the repair shop is generally divided into four: 1

1. Manufacturer Overview

| Location | Guangdong,China |

| Year Established | 2009 |

| Annual Output Value | |

| Main Markets | South America20.33% Africa 2.32% Mid East 3.39% Eastern Asia 4.64% Central America 2.14% Northern Europe 5.14% Domestic Market 62.04% |

| Company Certifications | ISO 9001:2008;ISO 14001:2004 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Guangzhou,Shenzhen |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Calcium Silicate Board Siding Plank with EPS Rigid Foam Board Insulation

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Square Meters m²

- Supply Capability:

- 100000 Square Meters per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords