Insulated Rubber Plastic Thermal Insulation Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Flexible Rubber Plastic Insulation Material Product Description

Rubber plastic is a high quality heat-insulating and heat-preservation material which use but yronitrile rubber and polyvinyl chloride(NBR,PVC) as main raw materials. The production process includes mixing, tensing and continuous extruding , heating and foaming.

2.Main Features of Rubber Plastic

-Lower heat-conductivity-Higher fire-blocking performance-Damp-proof and Water-proof-Softness-Neat and -Easy to install easy handing and storage-Good flexibility and tenacity

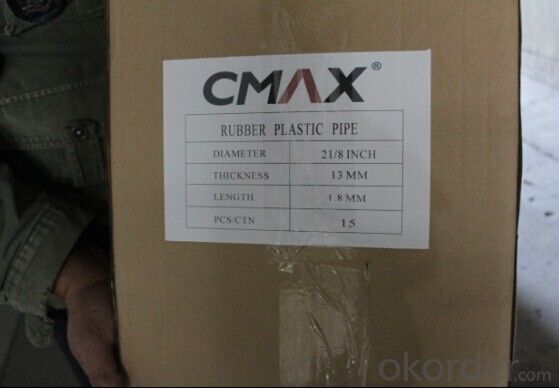

3.Rubber Plastic Images

4.Rubber Plastic Specification --Rubber Plastic Sheet

Density(kg/m3) | 40-90 | ||||

Thickness(mm) | 10 mm | 15 mm | 20 mm | 25 mm | 30 mm |

Length (m) | 20 | 20 | 10 | 10 | 10 |

Width (m) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

5.FAQ

①How about your company?A world class manufacturer & supplier of HVAC materials,is one of the large-scale professional investment building materials production bases in China.

②How to guarantee the quality of the products?We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase? In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Is it safe to use old aluminum foil facing as a cutting surface for vegetables and fruits?

- <p>Using old aluminum foil facing as a cutting board is not recommended. Aluminum foil is not designed to withstand the sharp edges of knives and can easily tear or puncture, posing a risk of injury. Additionally, the foil can transfer aluminum particles to the food, which may not be safe for consumption. Instead, use a proper cutting board made from materials like wood, plastic, or bamboo that are designed to handle knives and protect both your food and your safety.</p>

- Q: Is it possible to substitute traditional wooden flooring with black fiberglass tissue in a residential setting?

- <p>While black fiberglass tissue has properties that make it suitable for certain applications, it is not typically used as a direct replacement for traditional wooden flooring in homes. Fiberglass is more commonly found in industrial or marine settings due to its strength and resistance to moisture and corrosion. Traditional wooden flooring offers a warmth and aesthetic that fiberglass cannot replicate. However, for specific uses where durability and resistance to water are needed, fiberglass could be considered, but it would require professional consultation to ensure it meets safety and structural requirements.</p>

- Q: Insulation board and holding plastic from the chemical reaction? Insulation board dip in the glass, with the structure of plastic line

- Foam cement, the formation of a certain tension of the foam, and then the foam and cement slurry at the same time mixing, mixing process will continue to expand the cement, when the expansion effect to a pre-set ratio can be formed after the foam cement. Foaming is divided into physical and chemical methods of two kinds of foam, which is the physical method of foaming foam is the use of air compressor (that is, foaming machine) to form a bubble with a certain tension, and then foam and cement At the same time mixing, mixing process will continue to expand the cement, when the expansion effect to a pre-set ratio can be formed after the foam cement. Chemical foam, but refers to the blowing agent (liquid / powder solid) added to the cement slurry for mixing, the chemical reaction to release the gas so that the cement volume continues to expand, the expansion effect to the pre-formula set the state to form foam cement The Polystyrene foam board - also known as foam board, EPS board is made of volatile liquid blowing agent containing polystyrene beads, heated by the preheating in the mold after heating the formation of white objects, its fine The structural characteristics of obturator

- Q: How to convert thickness if the heat insulation effects of glass wool board and rubber and plastic board is the same?

- Calculated in accordance with the respective heat insulation layers

- Q: What is the production cost for black fiberglass tissues?

- <p>The cost to produce black fiberglass tissues varies and depends on several factors including the raw material costs, production scale, labor, energy consumption, and market demand. Fiberglass itself is made from silica sand, which is melted and spun into fine fibers. The addition of color, in this case, black, will add to the cost. However, without specific details on the production process, quantity, and current market prices for materials and labor, it's challenging to provide an exact figure. Generally, the cost can range from a few dollars to tens of dollars per square meter, but this is a rough estimate and actual costs may differ significantly.</p>

- Q: What are the potential health hazards linked to cooking with aluminum foil?

- <p>Cooking with aluminum foil is generally considered safe, but there are some potential health risks. Aluminum can leach into food, especially when it comes into contact with acidic or salty foods at high temperatures. This could lead to increased aluminum intake, which has been linked to neurological disorders like Alzheimer's disease, although more research is needed to establish a definitive link. Additionally, aluminum foil can cause burns or injuries if not handled properly. It's important to use foil responsibly, avoiding direct contact with food when possible, and to follow proper food safety guidelines.</p>

- Q: Is there a concern that aluminum from aluminum foil can seep into food during cooking or storage?

- <p>There is minimal risk of aluminum leaching from aluminum foil into food. Aluminum foil is generally safe for cooking and food storage when used properly. The risk increases with acidic or alkaline foods and high temperatures, but under normal cooking conditions, the amount of aluminum that could leach is negligible. However, it's best to avoid wrapping food in aluminum foil for long periods or at very high temperatures to minimize any potential exposure.</p>

- Q: The main body of the building is oval, the outermost is a closed glass curtain, shear wall structure more

- Building energy-saving materials: microelectronics, optoelectronics, new energy, chemical, LOW-E glass, gypsum board, etc. are new energy-saving areas. External wall insulation is an important part of the building energy efficiency system, the insulation function of the polyurethane market demand is better.

- Q: Is it possible to use aluminum foil facing as a substitute for a roasting pan?

- <p>While aluminum foil facing can be used in some baking situations, it is not recommended to use it as a direct substitute for a roasting pan. Aluminum foil is not designed to withstand the high temperatures of a roasting process and can melt or warp, leading to uneven cooking and potential safety hazards. A proper roasting pan is made to handle high heat and distribute it evenly, ensuring that your food cooks properly. For best results and safety, use a designated roasting pan or a baking sheet with a higher heat tolerance.</p>

- Q: What is the price of glass wool felt ?

- Wool felt volume: 1.2 X 1 X 0.5 = 0.6 cubic meters. The price of one wool felt: 1100 * 0.6= 660 yuan. Wool felt area: ?1.2 * 1 =1.2 m2. Price of one square meter wool felt : 660 / 1.2 =550 yuan

Send your message to us

Insulated Rubber Plastic Thermal Insulation Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords