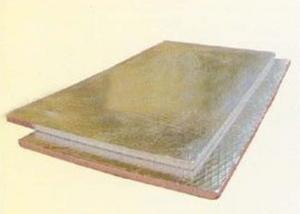

Bitumode App Bitumen Waterproof Membrane with Extruded Polystyrene (XPS) Rigid Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 Rolls roll

- Supply Capability:

- 60,000.00 Square Meters per Day roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description of BITUMODE APP Bitumen Waterproof Membrane

1. Type: Waterproof Membrane

2. Model: ALPHA - P

3. Reinforcement: Polyester

4. Use: Roofing System

5. Thickness: 3 or 4 mm

It is a torch-applied APP modified bituminous membrane that is reinforced with either fiberglass, polyester, or fiberglass /polyester combinations strategically located in the modified bitumen compound to incorporate additional performance characteristics into the membrane.

The net results are modified bitumen membranes with superior weatherability; strong and stable, yet accommodating to mechanical and thermal loads.

Available Range of BITUMODE APP Bitumen Waterproof Membrane

The standard range of our products is shown in the accompanying schedule. The typical thickness available are 3 and 4 mm. surface finishes can be polyethylene film on both sides; one side polyethylene and one sand; or granule finish on upper surface . The nominal length of each roll is 10 meters and the nominal width is 1 meter. Custom specifications can be designed based on the need of the clients.

Composition of the Product 1-Polyethylene, fine sand, or granules 2-Compound 3- Reinforcement 4- Compound 5- Polyethylene film

It is high quality torch applied waterproofing membrane, modified by APP and APAO with Polyster Reinforcement

- Q: What is the difference between extruded polystyrene board and XPS insulation board?

- Is a normal phenomenon, frost in the frost when the frost, and a temperature probe.

- Q: How is the flame and combustible defined by the naked eye? I burn the B1 level and B2 level XPS board is different? Question added: detection time is longer, can quickly and intuitively identified? More

- Air-conditioned room can not have flammable gas, in order to avoid explosion and fire do not frequent switch air conditioner, because the compressor starts when the current is running a lot of times the current, easy to burn the compressor motor 3) Do not put things on the outdoor unit of the air conditioner to avoid air conditioning noise. It is a great persecution for the air conditioner. The temperature of the general air conditioner is adjusted to 26 ° C to 28 ° C. , To avoid excessive power consumption next to the air conditioner must not be twitching Fengqi gong bite astringent ax to have a high temperature heat source, so as not to heat the panel deformation

- Q: Why extruded board (XPS board) is the best insulation board material

- Should belong to the template and support system. Full scaffolding is generally used for single-storey building, hall and other high-rise, large building between the top of the building decoration. By the pole, cross bar, bracing, scissors and other components.

- Q: Sound insulation and polystyrene insulation board which sound insulation better?

- The best bamboo pole, or plastic, aluminum alloy, then there is no child at home can have a child, then it is dangerous to fall easily hit people

- Q: Roof insulation layer is extruded polystyrene foam plate how set the amount of set

- A type is generally used for pool or wear interior wall, B type for wearing structure (building) building facades Type I seals are suitable for general waterproofing requirements and Type II is suitable for tighter watertight requirements Applicable temperature range: -20 ° C ~ +80 ° C When the wall and pump or booster equipment into the inlet and outlet pipes, it is appropriate to set up a flexible connection at the connection I remember that we are usually the construction of the pipe through the casing into the pool, and then sealed with oil linen casing

- Q: Steel plant wall plug color steel tile, the glass glass inside the glass, hanging in color steel, how construction? How is the cost associated with a single sandwich panel?

- More than 24 meters need to use cantilevered scaffolding, and the spacing of not more than 20 meters

- Q: Extruded Polystyrene Board, Polystyrene Foam Board and Expanded Polystyrene Board

- The key depends on your choice of waterproof construction and product quality, we recommend you choose Dongfang Yuhong waterproof products and standardized construction team, the East Rainbow is the best quality waterproof listed enterprises RPUF-371 sprayed foam polyurethane waterproof insulation integrated system " Rainbow "spray foam polyurethane waterproof insulation integrated system is composed of rigid foam polyurethane foam waterproof insulation integrated material and the protection of the surface layer composition

- Q: Polystyrene foam hard insulation board will not be harmful to the human body, right?

- Building safety production management issues, please choose the answer (multiple choice)

- Q: What is the difference between an extruded board and an XPS extruded board?

- Foam plastic plate insulation effect, hinder the outdoor temperature affect the indoor temperature, can play the role of Dongnuanxialiang. . the snow has the role of heat insulation, isolated 礌 礌 礌 蕺 蕺 蕺 蕺 scrapped wheat and outside the air contact, on the one hand to prevent the wheat freeze and death, on the other hand have the effect of refrigeration . to the thicker glass When the water is turned down, the inner glass is exposed to rapid heat, and the outer glass is in contact with the cold air of the cup, so that the expansion of the inner and outer walls causes the difference.

- Q: How to distinguish between good and bad insulation board insulation board

- Which is good to know how to save the cheek version of the wedge is not very simple can be conclusive. The use of the environment on the impact of different materials, expensive reasons can not be used as a good reference for things, such as the general situation Coke than boiled water expensive, but when the medicine, you say cola good or boiled water is good. 2 kinds of material strength is almost, aluminum good point, toughness is much better PP plastic, but only at room temperature, once the temperature is too high or the bottom, the plastic will be easy to break. Now the plastic process is very developed if the plastic stent is used with some new advanced technology that can improve some of the plastic defects to achieve the metal can not reach the firmness. It is best to buy some, practice to compare it

1. Manufacturer Overview

| Location | Cairo . Egypt |

| Year Established | 1996 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe |

| Company Certifications | ISO 9001-2008 ;ISO 14001;CE Mark |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | 50,000-100,000 square meters |

| No. of Production Lines | 10 |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Bitumode App Bitumen Waterproof Membrane with Extruded Polystyrene (XPS) Rigid Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 Rolls roll

- Supply Capability:

- 60,000.00 Square Meters per Day roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords