Insulated Rubber Plastic Tube for Chilled Water Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Flexible Rubber Plastic Insulation Material Product Description

Rubber plastic is a high quality heat-insulating and heat-preservation material which use but yronitrile rubber and polyvinyl chloride(NBR,PVC) as main raw materials. The production process includes mixing, tensing and continuous extruding , heating and foaming.

2.Main Features of Rubber Plastic

-Lower heat-conductivity-Higher fire-blocking performance-Damp-proof and Water-proof-Softness-Neat and -Easy to install easy handing and storage-Good flexibility and tenacity

3.Rubber Plastic Images

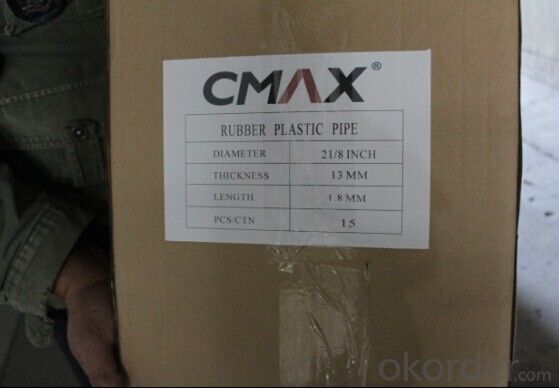

4.Rubber Plastic Specification --Rubber Plastic Sheet

Density(kg/m3) | 40-90 | ||||

Thickness(mm) | 10 mm | 15 mm | 20 mm | 25 mm | 30 mm |

Length (m) | 20 | 20 | 10 | 10 | 10 |

Width (m) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

5.FAQ

①How about your company?A world class manufacturer & supplier of HVAC materials,is one of the large-scale professional investment building materials production bases in China.

②How to guarantee the quality of the products?We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase? In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: do I have to blow insulation in the roof of my mobile home if I install foam insulation under a meatle roof?

- Some mobiles have a vented attic and some don't. If your attic is vented, the foam on the roof won't help insulate inside the house. I've blown insulation into a mobile home attic before (vented attic), but some mobiles one can't (not vented attic). There are different variations of attic venting, dictating if you can blow in or not. I would add insulation anyway, if you can, mobiles usually skimp on attic insulation, even if they are "certified".

- Q: Is it possible to use black fiberglass tissue in the manufacturing of furniture?

- <p>Yes, black fiberglass tissue can be used for furniture manufacturing. It is known for its strength, durability, and resistance to various environmental conditions, making it suitable for creating sturdy and long-lasting furniture. Fiberglass is often used in outdoor furniture and certain types of modern indoor furniture due to its versatility and ability to be molded into various shapes. However, it's important to consider the aesthetic appeal and the specific requirements of the furniture design when choosing to use black fiberglass tissue.</p>

- Q: What are the requirements for filling the glass wool insulation materials?

- It depends on design requirements, local climate and budget.

- Q: How to strengthen the construction management and construction quality control

- You can Google Oriental Rainbow's official website, there are rainbow days cat flagship store and other links will have the price and product display, you can also contact Rainbow customer service, it is recommended that you choose the East Rainbow waterproof products and standardized construction team, the East Rain rainbow is the best quality waterproof listed companies RPUF-371 sprayed rigid polyurethane waterproof insulation integrated system "rain rainbow" spray foam polyurethane waterproof insulation integrated system is made of foam polyurethane foam waterproof insulation integrated material and protective surface layer constitute

- Q: We have recently moved into a house in Australia with a tin roof. There is a layer of 5cm batts on the rafters in the roof space, but the temp is 10-15 degrees C higher up there than in the house (with all the windows and doors open). I don't want to get air-conditioning, is there another way to insulate the roof and cool the house?

- The attic will always be warmer than the house--that's the point of the insulation--to separate the heat in the attic from the cooler air in the house. However, to improve it even more, add insulation on the ceiling joists (not the roof rafters). Make sure there is plentiful ventilation in your attic (when the wind blows, you should feel it blowing inside your attic). Eave vents, ridge vents--it doesn't really matter which ones you use--but you have to have enough for the air to really flow.

- Q: What is the variance in cost between black and white fiberglass paper?

- <p>The price difference between black and white fiberglass paper can vary significantly based on factors such as quality, thickness, and market demand. Generally, black fiberglass paper may be slightly more expensive due to the additional dyeing process. However, the exact price difference is not fixed and can fluctuate. It's best to check with specific manufacturers or suppliers for current pricing as it can change over time and differs by region.</p>

- Q: What are the features of glass wool decorative acoustic?panel?absorber suspended ceiling?

- 1, Excellent decorative effect. Mineral wool acoustic board has various patterns and reliefs, stereoscopic model, reflecting ancient glory and modern fashion, really refreshing. 2. good thermal insulation property. Mineral wool acoustic board is good thermal insulation material which can be make the house warm in winter and cool in summer and save energy for users because it has low heat conductivity coefficient. 3. sound absorption and noise reduction. The main raw material of mineral wool acoustic board is ultra-fine mineral wool fibre whose density is about 200 ~ 450Kg / m, so it has many perforative micropores which can effectively absorb sound waves and reduce sound wave reflection so as to improve indoor tone quality and reduce noise. 4. fireproof. Since the mineral wool is an inorganic material, it will not burn, and mineral wool acoustic board has very low content of organics, thus making it meeting requirements of Class B1 non-combustible. And our products have been able to reach non-combustible Class A . 5. Green and eco-friendly, regulating air. Mineral wool acoustic board does not contain harmful substances. It contains active groups which can absorb harmful gases in the air and its porous structure can absorb and release water molecules so as to purify the air and adjust indoor air humidity . 6. moisture-proof and insulation. Since mineral wool acoustic board contains a large number of micropores and has releatively large surface area, it can absorb and release water molecules in the air and regulate indoor air humidity. It can be regarded as a decorative board that can breath.

- Q: This question asks for methods to properly store black fiberglass tissue to avoid damage or deterioration.

- <p>To store black fiberglass tissue and prevent damage or degradation, follow these steps: Store the tissue in a cool, dry place away from direct sunlight and moisture. Keep it in a sealed, airtight container to protect it from dust and contaminants. Avoid stacking heavy objects on top to prevent compression damage. If possible, use a container with a desiccant to control humidity. Regularly check for any signs of damage or degradation, and replace the tissue if necessary. Proper storage will help maintain the integrity and performance of the fiberglass tissue over time.</p>

- Q: To ask why the use of clamps connected to the spray pipe after the flush again after the water there will be a lot of hook link position leakage phenomenon? Thank you! The The

- The radial force of the seal is far greater than the axial force of the connecting bolts but all the axial force washers 窢 field urging 讵 peculiar aldehyde support, good self-sealing effect by the pipeline through the media rubber ring pressing force pressure more sealing performance of the more pressure to prevent the pressure of the rubber ring to the inner diameter of the tube end of the interface diameter Preload to prevent the media pressure leakage and the blue compared to the higher the pressure of the pipe the more the advantages of the more dangerous the pipe junction at the flexible state of the clamp and the tube between the gap between the clamp clamp a small number of adjacent pipe to allow the corner tube Pipe pipe between the end of the gap to allow the axial shift of the pipeline to adapt to the expansion and contraction of the pipe; pipe interlocking effect reduced 70% mechanical vibration

- Q: This question asks about the distinctions between various grades of black fiberglass tissue, likely referring to the material properties and applications.

- <p>Different grades of black fiberglass tissue are distinguished by their weave patterns, thickness, tensile strength, and heat resistance. Grade E glass is the most common and offers a balance of strength and cost-effectiveness. Grade S glass is stronger and more durable, used for high-stress applications. Grade C glass is the strongest but also the most expensive, often used in aerospace and military applications. Each grade has specific uses based on the required properties for the end product, such as electrical insulation, reinforcement in composite materials, or high-temperature resistance.</p>

Send your message to us

Insulated Rubber Plastic Tube for Chilled Water Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords