A variety of colors of insulating glass 8mm+12A+6mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

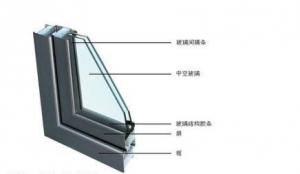

we introduced the advanced production lines (with automatic coating removing, automatic sealing system) and equipped with reverse osmosis deionized water preparation and storage equipment, automatic aluminum spacer bending equipment, low-e glass coating removing equipment, which is able to produce all kinds of specifications of insulating glass for customers. The production lines that are equipped with automatic vertical sealing system, abandon the disadvantages of traditional horizontal sealing (there will be no patch phenomenon), make the processed insulating glass more flat and smooth..

Insulating glass size specifications:

Maximum processing size: 2440 mm * 3500mm

Minimum processing size: 200 mm * 200 mm

Aluminum spacer specifics: 6 mm, 9 mm, 12 mm, 16 mm

Glass thickness: 3 mm to 19 mm

Insulating Glazing

A. All glass can be processed before assembly

B. Glass transfer onto the glass loading machine

C. Edge coating removing of coated glass

D. Wash and clean strictly

E. Automatic bending for air spacer

F. Automatic molecular sieve filling

G. Automatic butyl rubber applying

H. Automatic framing

K. Automatic scanning positioning

L. Automatic double sealing

M. Transfer by sucking disc

N. Conner finishing

O. Glass on the shelves till solidification

P. Customized wooden cases according to the size of glass

Q. Transfer the glass into the specific wooden cases

R. Leading Time:10 days for an average area of 1000 square

meters tempered glass

S. Trade terms: FOB and CIF.

T. Payment Terms: By TT, 30% deposit to start producing,

full amount balance paid before delivery.

U. The container loading after the package checking

- Q: What is this wall of glass building material called?

- Architectural glass: Humans learn to use glass has been a thousand years of history, but more than 1,000 years, as the development of architectural glass material is relatively slow. With the development of modern science and technology and glass technology and the improvement of people's living standard, the function of architectural glass is no longer just to meet the lighting requirements, but to have to adjust the light, thermal insulation, security (bulletproof, anti-theft, fire Radiation, anti-electromagnetic interference), art decoration and other characteristics. With the continuous development of demand, glass molding and processing technology has also been a new development. Now, new technologies such as interlayer, tempered, ion exchange, glazed decoration, chemical thermal decomposition and cathodic sputtering have been developed to increase the amount of glass in the building and become the third largest building behind cement and steel material.

- Q: Is there a way to reduce the noise

- With the continuous development of society, noise pollution problems are more and more serious, especially in the city of traffic noise constantly plagued the general public, here mainly to introduce some of the static noise glass knowledge for everyone to share!

- Q: the usage of glass in building construction has been in constant increase in the past decade.these glasses would certainly increase the volume of reflection in the atmosphere..doesn't this add to the temperature rise ?

- No. The light has to land somewhere. If the building is reflective, then the light lands on the ground in "front" of the building and heats that. If it is not, then the building is heated. Of course, covering up the grass and ground with building affects the heating of the air. And if you are near a reflective building, the direct radiant heating on your body increases because you are getting direct rays of sun and the reflected rays of sun from over there that would normally not hit you.

- Q: New glass features

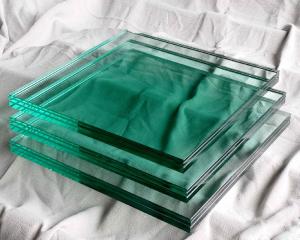

- plate glass Flat glass is not processed by other flat glass products, also known as white glass or clean glass. According to the production method is different, can be divided into ordinary flat glass and float glass. Flat glass is the largest in the building glass, the most used one, mainly for doors and windows, from lighting, enclosure, insulation, sound insulation and other effects, but also further processed into other technical glass of the original film. Flat glass according to its use can be divided into window glass and decorative glass. According to the national standard "ordinary flat glass" and "float glass" provisions, the glass according to its thickness can be divided into the following specifications: In accordance with national standards, flat glass according to its appearance quality classification grading, ordinary flat glass is divided into superior products, first-class goods and second-class three grades. Float glass is divided into three grades: superior grade, first grade and qualified product. Flat glass use has two aspects: 3 ~ 5mm flat glass is generally used for doors and windows of the lighting, 8 ~ 12mm flat glass can be used to cut off. Another important use is as the original film of tempered, interlayer, coated, hollow and other glass.

- Q: 2680 Building glass visible light transmission ratio is invalid?

- Insulating glass is characterized by environmental protection with sound insulation and other advantages "dew point detection" is to test the airtight insulation to ensure that the air cavity is independent and stable drying "visible light transmission ratio" is for different design requirements need to use different insulating glass products Conducting different substrate transmittance is not the same as "shading coefficient" is for coated glass or.

- Q: What is the main part of the safety glass used in the building?

- Mainly used in public safety caused by hidden parts, such as the door, glass curtain wall, and the car front block, bank counter operating area, to prevent radiation, splash, observation and so on.

- Q: Is there a place that sells glass panels to be mounted together so you can build your own glass dome bedroom? I don't mind a 7-8 foot wall and then a dome on top.

- Yes okorder / you can ask with the details of your requirements. They answers promptly. Now you can complete your dream bedroom quickly. Wish one day I can visit your home to see it.

- Q: Benjamin Franklin built the Glass (H)Armonica in 1762 I want to know what it was made of and how.

- Benjamin Franklin Armonica

- Q: Glass quality standards

- Glass sub-kiln and small kiln of the sub-kiln is the float glass. Float glass thickness uniformity, transparency is good, through the glass to see things will not be deformed, high quality. Small kiln glass: thin uneven, through the glass to see things deformation, the quality of the times. Glass thickness: from 2 mm to 2 to 20 mm.

Send your message to us

A variety of colors of insulating glass 8mm+12A+6mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords