Cloth Bag For Vacuum Cleaner

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Pieces watt

- Supply Capability:

- 1500000 Pieces per Month watt/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

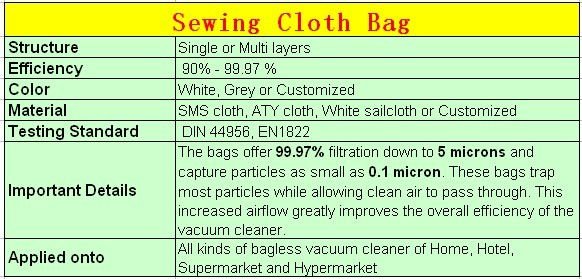

Detailed Product Description

1:High Dust Retention Rate

2:Low Resistance

3:Antimicrobial,Adsorption,Deodorization

4:Excellent Packaging

5:Good Appearance

- Q: What is the reason for the strong drop in the broken filter bag of the cement mill dust filter bag

- Wear and tear. There are three reasons for the wear of cloth dust filter bags: The distribution of air turbulence is uneven. The distribution of air turbulence results in the area of the filter bag which has a high velocity of dust vapor, which causes the filter bag to wear down and the life expectancy decreases. The gas filtration rate is high. Too high a filter speed can cause a lot of dust, and the fabric fibers of the filter are easily damaged. The filter bag is too small. In the lower part of the filter bag, the abrasion is more common, the wear is more than one side, the lower part is the most serious, the upward gradually reduces, the local sewing thread will be ground broken.

- Q: Why is the filter bag material PE a polyester, not a polyethylene

- Polyester: the general name of a polymer compound that is condensed by diglycol or polyols and dibasic acid or polyacid. Include polyester resin, polyester fiber, polyester acid glue etc. Polyester, Polyethylene terephthalate (PET) belong to the high molecular compound. Consists of terephthalic acid (PTA) and ethylene glycol (EG) through polycondensation produce polyethylene terephthalate (PET), part of the PET and ultimately generated by underwater pelletizing. Purpose: fiber grade polyester chip is used to make polyester staple and polyester filament, which is the raw material for fiber and related products of polyester fiber. Polyester film and bottle, and other purposes at the same time, widely used in packaging industry, electronic appliances, medical and health care, construction, automotive and other fields, the packaging is one of the largest non polyester fiber application market, is also the fastest growth in PET. It can be said that the polyester slice is an important intermediate product that connects the petrochemicals and the products of several industries.

- Q: Filtration efficiency of liquid filtration bag

- Different companies have different test methods and efficiency requirements of filter bag accuracy, some are defined as 80 ~ 85%, some are defined as 50 ~ 70%.

- Q: How do you use a filter bag?

- In order to improve the use of filter bags, we should pay special attention to this knowledge in ordinary times. If we have different problems, we need to find solutions. First, the bag is broken. The shape of the filter bag and the installation method of the filter bag determine the location of the filter bag easily broken, which can be inspected and repaired. Secondly, the filter bags age. For reasons that are caused by the following reasons, reasons should be investigated, taking the elimination measures and changing the filter bags. (1) hardening and contracting due to unusually high temperature; (2) due to contact with the vapor of an acid, alkali or organic solvent; 3) react with water.

- Q: What is the reason for the dust bag to be broken for a period of time

- This is a regular change. Bad quality is a good thing,Or it will be broken for too long.

- Q: What is the cleaning method of the filter bag

- So that's how you clean the filter bag. Have you learned it? One thing you need to be aware of is that you have to choose the quality of the filter, so the filter will be good. In order to select a quality filter, you must go to the hui long filter purification co., LTD. Huilong filtration purification co., LTD. Is a company that "relies on science and technology to revitalize the famous nationality industry, and make a world brand" Culture and "customer first, win-win cooperation". We are always committed to the continuous development of the filter business, continuous development, innovation and progress. Pursue the peak of technology. Create a world class filter "carrier" filter

- Q: How is the filter bag type and filtration efficiency

- Viscose particles in the more, especially the more big particles (diameter greater than 15 1 xm) and spinnability of spinning and viscose fiber the greater is the impact on the quality of the finished product, these impurities cause increased congestion, breakage, spinneret spinning when produce plastic blocks and hair silk, causing changes in the size.

- Q: How is the filter bag chosen?

- About high flue gas temperature compare, such as: chemical, carbon black (white carbon black), and iron blast furnace gas, cement kiln, and factory of calcium carbide kiln tail gas, forging, steel mills, asphalt concrete mixing asphalt smoke, refractory brick kiln gas, coking gas, etc., one is because of these gas containing dust dust because of restricted by resistivity is not suitable for electrical dust collector to collect, can only use dust filter bag or other methods to collect;

- Q: How about the filter bag of the washing machine

- If you have a screen of the original filter, put a silk sock on the frame and wrap it around the outside with a strong thread

- Q: How to maintain the filter bag?

- It is also easy to jam in a cloth bag. Water is the most frequent. So common to avoid improper boot, be careful not to at the time of filter resistance big boot, boot, just below the dew point when there is air infiltration due to the dust collector in the first meet high temperature to low temperature, moisture, are apt to happen.

With real technical strength, professional manufacture experience, and featuring integrity services, we have built long-term and stable business relationships with famous companies around the world .Now, our company has become the leader in the filtration field.

.

1. Manufacturer Overview

| Location | Zhejiang,China |

| Year Established | 2001 |

| Annual Output Value | |

| Main Markets | |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cloth Bag For Vacuum Cleaner

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Pieces watt

- Supply Capability:

- 1500000 Pieces per Month watt/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords