Polyester Non Woven dust Bag Filters for filtration

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

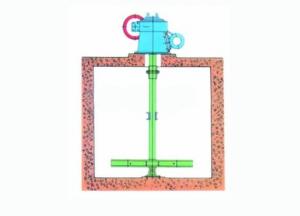

Overview:

Our company can offer all kinds of polyester non woven polyester filter bags. Polyester filter bag is most widely used in the temperature between 130 centigrade and 150 centigrade. Compared with other filter cartridge, it also has better anti-abrasion and higher ratio performance. They are excellent used in industrial fume deducting and dust collection.

Application: steel, cement, chemical industry, food processing, etc.

Polyester needle punched felt is made from polyester fiber. The material has better anti-abrasion and higher porosity, good twist resistance. It is a kind of widely applied normal temperature filter material.we suggests the normal application must be 15-20℃ above the dew point temperature.

Features:

Good air permeability

high porosity

flat and smooth surface

high dust collection efficiency

long service life

We pursue quality products, reasonable price and excellent service.

When you choose to use the products of our company, you only need to call or write to the company, we will solve all you troubles and give you a satisfactory results.

Specification:

Material | 100% Polyester |

Weight | 500±25g/m2 |

Air Perm | 80-140L/m²S |

Warp Tensile Strength | >1200N/5×500px |

Weft Tensile Strength | >1200N/5×500px |

Warp Elongation | <35%< span=""> |

Weft Elongation | <45%< span=""> |

Continuous Temperature | 130℃ |

Surge Temperature | 150℃ |

Moist Temperature | 94℃ |

Finishing | Singed, smooth, stabilization |

Chemical Resistance: | Acid Fair |

Alkalis Fair | |

Oxidising Agents Good |

Polyester media may be attacked by moist heat hydrolysis, strong acid or strong alkalis. To avoid such accurrences, please operate in an environment in accordance with the above recommendations.

Data are taking from production runs to show “typical “properties.

This is to be used as a guide and all the data can be adjusted according to buyer requirements.

- Q: Can industrial water filters be filtered by domestic water?

- water softener: generally use recycled sodium resin displacement of calcium and magnesium ions in water, only to soften and reduce the hardness of water, can not be purified, can not remove all kinds of harmful pollutants in water.

- Q: How to choose air filter

- The purification effect of four, the workshop is influenced by the type of air inlet and outlet of the air filter: 360 degree circular design, also has a one-way inlet and outlet air, if not by restrictions on products placed on the pattern of a room, you should choose different import wind design products, mainly have two kinds, including the development of air HEPA filter and ordinary HEPA tuyere.

- Q: Where is the manufacturer of pure water equipment?

- The pretreatment system, reverse osmosis system, intermediate water tank, coarse to fine mixed bed and mixed bed of pure water tank, water pump, UV sterilizer, precision filter, water polishing resin, the object (more than 18M Omega.CM) (traditional technology)

- Q: How about water treatment equipment, water treatment equipment?

- The biomass in the biological tank can be maintained at a high concentration, and the waste sludge is less than the process, and the ammonia nitrogen can be effectively removed. The suspended substance and turbidity of the effluent are close to zero, and the bacteria and viruses in the effluent can be largely removed

- Q: Selection of filtration equipment for filtration equipment

- The filtration of fine particles with solid C1% can be carried out by the aid of a filter aid, a horizontal vane press filter or a cylindrical vacuum filter, etc., and the effect is better.

- Q: What is an industrial oil mist collector?

- The first rotary screw filter intercepts solid particles from the suction medium first.

- Q: Principle of on-line self-cleaning filter for industrial water treatment and forced backwashing

- wash wash is put into operation before the preparation work is mainly to restore contact filter filtration and depth filtration effect, to ensure the water quality of medium SDI (pollution index) = 4.

- Q: The south is well-known, the strength of the production of filter cloth or industrial filter cloth manufacturers?

- Fushun Yue Sheng Industrial filter cloth company

- Q: How to calculate the air volume required for industrial oil mist filters?

- regardless of the use of the nature of the liquid, air suction hood = volume *360 air inside the shell, wherein the cover shell of air volume = length * width * high -

- Q: Industrial factories with large water purification equipment, what kind of business will do? How much will the large water purification equipment cost?

- Water purification equipment, many environmental protection companies and water treatment equipment companies do.

Send your message to us

Polyester Non Woven dust Bag Filters for filtration

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords