Industrial Aluminum Foil Sheets - Aluminum Sheet Mill Finished 1060 1050 1100 3003 5005 5052 6061 6063

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCTS ADVANTAGE:

1: Thousands of already-made extrusion moulds are free for customer;

2: Any surface treatment is acceptable to make to meet your needs;

3: Strict quality control for your goods, very little scratch;

4: Free surface and both edges of profiles are smooth and with no burr;

5: Standard alloy composition;

PRODUCTS CHEMICAL COMPOSITION:

| Alloy | Chemical Composition % | ||||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al | ||

| Single | Tol | ||||||||||

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | 0.05 | 0.03 | 0.03 | - | 99.6 |

| 2011 | 0.4 | 0.7 | 5.0-6.0 | - | - | - | 0.3 | - | 0.05 | 0.15 | Remain |

| 2014 | 0.5-1.2 | 0.7 | 3.9-5.0 | 0.4-1.2 | 0.2-0.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 2024 | 0.5 | 0.5 | 3.8-4.9 | 0.3-0.9 | 1.2-1.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | - | - | 0.1 | - | 0.05 | 0.15 | Remain |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | 0.1 | - | 0.05 | 0.15 | Remain |

| 6060 | 0.3-0.6 | 0.1-0.3 | 0.1 | 0.1 | 0.35-0.6 | - | 0.15 | 0.1 | 0.05 | 0.15 | Remain |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 6063 | 0.38-0.43 | 0-0.25 | 0.1 | 0.1 | 0.5-0.6 | 0.1 | 0.1 | 0.1 | 0.05 | 0.15 | Remain |

| 6082 | 0.7-1.3 | 0.5 | 0.1 | 0.41 | 0.6-1.2 | 0.25 | 0.2 | 0.1 | 0.05 | 0.15 | Remain |

| 6463 | 0.2-0.6 | 0.15 | 0.2 | 0.05 | 0.45-0.9 | - | 0.05 | - | 0.05 | 0.15 | Remain |

| 7003 | 0.3 | 0.35 | 0.2 | 0.3 | 0.51 | 0.2 | 5.0-6.5 | 0.2 | 0.05 | 0.15 | Remain |

| 7005 | 0.35 | 0.4 | 0.1 | 0.2-0.7 | 1.0-1.8 | 0.06-0.2 | 4.0-5.0 | 0.01-0.06 | 0.05 | 0.15 | Remain |

| 7075 | 0.4 | 0.5 | 1.2-2.0 | 0.3 | 2.1-2.9 | 0.18-0.28 | 5.1-6.1 | 0.2 | 0.05 | 0.15 | Remain |

PRODUCTS DETAIL:

| Brand name | Bengal Aluminum |

| Aluminum products | Aluminum profile,Thermal break profile,Aluminum bar,Aluminum tube/pipe, Aluminum sheet,Aluminum heat sink section,Aluminum curtain wall,Aluminum handle,Aluminum frame,Aluminum rail,Aluminum accessory |

| Thickness | Mill finish profile thickness:0.7mm-3mm |

| Anodizing film thickness:over13μ | |

| Power coating film thickness:over13μ | |

| Length | General length:0-6m |

| Meet customers requirement | |

| Shape | Round,Flat,Square,Oval,Triangle,Pentagon, Hexagon,T,L, or customized requirement available |

| Surface treatment | Powder coating,Anodizing,Sand blasting, wood grain,electrophoresis, polishing,PVDF,etc |

| Deep process | CNC,Drilling,Milling,Bending,Cutting,Welding,etc |

| Colour | Silver, bronze,Black,Champagne,gold,White,Grey,Green,etc |

| Temper | T3-T8, O-H112 |

| Application | Windows and doors frame,Curtain wall,Furniture,Kitchen cabinet door,LED light,ceiling,machine,fences,Construction,Industrial,etc |

| Lead time | 8-20 days after the sample is confirmed by buyer |

| Mould fees | Free of charge if use existing mould |

| Charged by the size if open up a new mould | |

| Packing details | Packed with plastic protective film to protect each piece inside |

| Wrap to be bundles by waterproof craft paper | |

Packing ways depend on the profile goods design, we can meet customized requirement |

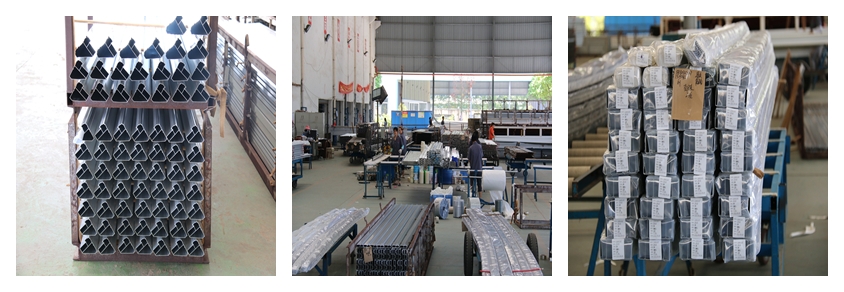

PACKAGING AND SHIPPING:

Your aluminum extrusion profile goods are always packaged to ensure that thay arrive safely on their long journey to you. The best packaging solutions depend on the design.We provide our customers with clear packaging consuting services. Normally, the products will be packed with plastic protective film to protect each piece inside and wrap to be bundles by waterproof craft paper outside.

Our Services

Onsite Factory Services | Onsite Factory Services |

|

|

We factory also provides the following services:

Engineering design

Research and development

Design consulting

Photos

- Q: 6061 what is the density of the aluminum plate?

- 6061 aluminum plate density:6061 aluminum plate is aluminum alloy, the density is calculated according to 2.9g/cm3.Calculation method:Aluminium plate weight (kg) =0.0000029 * * * * width * lengthAluminium tube weight (kg) =0.0000029 * wall thickness * (outside diameter wall thickness) * lengthFormula for weight calculation of aluminium bars (kg) =0.0000029 * radius * radius * length

- Q: This question asks for a method to determine the quantity of aluminum sheets required for a specific project.

- <p>To calculate the amount of aluminum sheets needed for a project, first determine the area that needs to be covered. Measure the length and width of the surface in question. Multiply these two dimensions to get the total area in square units (e.g., square feet or square meters). Next, consider the thickness and specific requirements of the aluminum sheets, as this may affect the number of sheets needed. Finally, divide the total area by the coverage area of one aluminum sheet (which can be found from the supplier or calculated if you know the dimensions and thickness of a single sheet). Round up to the nearest whole number to ensure you have enough material for your project. Always account for waste and additional material for cuts or adjustments.</p>

- Q: Are the aluminum sheets suitable for manufacturing lightweight structures?

- Indeed, aluminum sheets are exceptionally well-suited for the production of lightweight structures. Renowned for its low density, aluminum stands as one of the most lightweight metals on the market. This attribute renders aluminum sheets an exceptional option for a multitude of sectors that prioritize weight reduction, such as aerospace, automotive, and construction industries. Furthermore, aluminum boasts an impressive strength-to-weight ratio, enabling it to withstand substantial loads while remaining lightweight. Moreover, aluminum sheets exhibit exceptional corrosion resistance, rendering them suitable for both outdoor and marine applications. All in all, the combination of its lightness, strength, and durability positions aluminum sheets as the preferred choice for the production of lightweight structures.

- Q: What are the potential hazards or risks associated with the use and handling of aluminum sheets?

- <p>Safety issues related to aluminum sheets include the risk of cuts and lacerations from sharp edges, potential for eye injuries if aluminum particles or dust comes into contact with the eyes, and the risk of fire or explosion if aluminum dust is present in the air and ignited. Additionally, improper handling can lead to back injuries or other musculoskeletal disorders due to the weight of the sheets. Inhalation of aluminum dust over a long period may also pose health risks, although it's less common. It's crucial to use proper protective equipment and follow safety guidelines when working with aluminum sheets.</p>

- Q: Nissan A1100P aluminum plate is equivalent to what brand of domestic, where there are relevant information and instructions, mechanical design manuals or other materials manuals? Thank you.

- 1, aluminum plate A1100P equivalent to national standard AL1100 aluminum plate.2 and 1100 are pure aluminium, the content of aluminium is 99%, which can not be improved by heat treatment. With high corrosion resistance, electrical conductivity and thermal conductivity, and its small density, good plasticity, through pressure processing can produce all kinds of aluminum, but the strength is low. Other process properties are basically the same as those of 1050A. 1100 commonly used to have good machining performance, high corrosion resistance, high strength does not need not see, such as video and chemical handling and storage equipment, sheet metal products, hardware, hollow spinning drawing goods welding key combination, reflector, nameplate.

- Q: What are the different types of alloys used for aluminum sheets?

- There are several types of alloys commonly used for aluminum sheets, each with its own unique properties and applications. Some of the most common types include: 1. 1100 alloy: This alloy is pure aluminum with excellent corrosion resistance and good formability. It is often used for general sheet metal work, such as roofing and siding. 2. 3003 alloy: This alloy is similar to 1100 but with added manganese, making it slightly stronger. It is commonly used for applications that require moderate strength and good corrosion resistance, such as packaging and automotive parts. 3. 5052 alloy: This alloy is known for its excellent corrosion resistance, especially in marine environments. It also has good formability and weldability, making it suitable for various applications like fuel tanks, marine components, and architectural panels. 4. 6061 alloy: This alloy is one of the most versatile and widely used aluminum alloys. It offers excellent strength, weldability, and corrosion resistance. 6061 is commonly used in structural applications, such as aircraft parts, bicycle frames, and automotive components. 5. 7075 alloy: This high-strength alloy is often used in aerospace and military applications. It has excellent fatigue resistance and good machinability. 7075 is typically used for aircraft structures, missile parts, and high-stress components. These are just a few examples of the various types of aluminum alloys used for sheets. The specific alloy chosen will depend on the desired properties, such as strength, corrosion resistance, formability, and cost, as well as the intended application.

- Q: I may use the copper or brass for an inlay on a decorative piece of aluminum I'm working on.....

- aluminum okorder / so what you are finding is that aluminum will melt before the copper or brass...

- Q: Can aluminum sheets be embossed?

- Yes, aluminum sheets can be embossed.

- Q: How are aluminum sheets measured and specified?

- Aluminum sheets are typically measured and specified based on their thickness, width, and length. The thickness is commonly expressed in gauge or millimeters, while the width and length are provided in inches or millimeters. Additionally, the alloy composition and temper of the aluminum sheet may also be specified to meet specific requirements.

- Q: What are the cost considerations when purchasing aluminum sheets?

- When purchasing aluminum sheets, there are several cost considerations to take into account. First and foremost, the price of aluminum sheets is determined by the current market conditions. The price of aluminum is influenced by factors such as supply and demand, global economic conditions, and geopolitical events. Therefore, it is essential to stay updated on market trends and fluctuations to make an informed purchasing decision. Another cost consideration is the quantity of aluminum sheets needed. Purchasing in bulk or larger quantities often results in lower per-unit costs. However, it is crucial to assess the required quantity accurately to avoid excess inventory and unnecessary expenses. Additionally, the grade and quality of aluminum sheets can impact their price. Aluminum sheets are available in various grades, each with specific properties and performance characteristics. Higher-grade aluminum sheets, such as those with superior strength or corrosion resistance, tend to be more expensive. It is important to evaluate the specific requirements of the project to determine the appropriate grade of aluminum sheets needed. Transportation costs are another factor to consider when purchasing aluminum sheets. Depending on the supplier's location and the quantity ordered, shipping expenses can vary significantly. It is advisable to explore different shipping options and negotiate favorable terms to minimize transportation costs. Lastly, it is essential to consider additional costs such as processing, finishing, and customization. Some projects may require additional services like cutting, bending, or coating the aluminum sheets. These services can add to the overall cost but may be necessary to meet specific project requirements. Overall, when purchasing aluminum sheets, it is crucial to consider the current market price, required quantity, grade and quality, transportation costs, and any additional processing or customization needs. By carefully evaluating these cost considerations, one can make a well-informed decision and ensure the best value for their investment.

Send your message to us

Industrial Aluminum Foil Sheets - Aluminum Sheet Mill Finished 1060 1050 1100 3003 5005 5052 6061 6063

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords