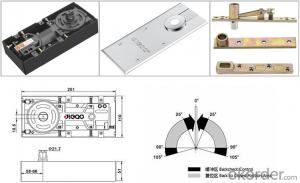

Hydraulic Floor Hinge/ Door Closer/Floor Spring for Glass Door/Floor Hinge for Glass Door FS-7300

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

INTRODUCTION

Floor Spring is used for glass door, and they can be used together with door clamp. Floor Spring can be opened with double sizes, and on this point, it is different from that of door closer, which can just be opened by one size. The key of technique lies on the loading seat under the main bearing, which decides the level of loading on the floor spring. Usually it can be opened from 300thousand or 1million times

FEATURES

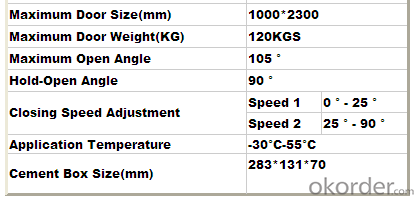

u Applicable for glass doors, wooden doors and the glass doors of metal frame and wooden frame.

u Floor spring comply to EN 1154 and GB standard , and fire-rated EN1634 standard.

u Maximum 500000 cycles tested without damage or maximum 7 years guarantee.

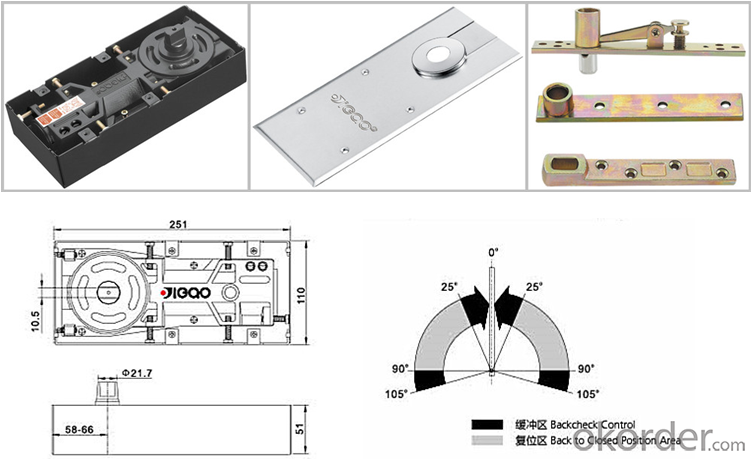

u Double ways opening with smoothly movement, hold-open at 90°.

u Closing speed and latching speed adjustable, latching point accurately at 0°

u Stainless steel cover plate, satin or mirror surface available.

u High quality casting iron floor spring body with 2 layers anti-rust coating.

u All spindle types available for different countries.

u Germany hydraulic machine oil and sealed rings, keep perfect working in cold temperature.

SPECIFICATION

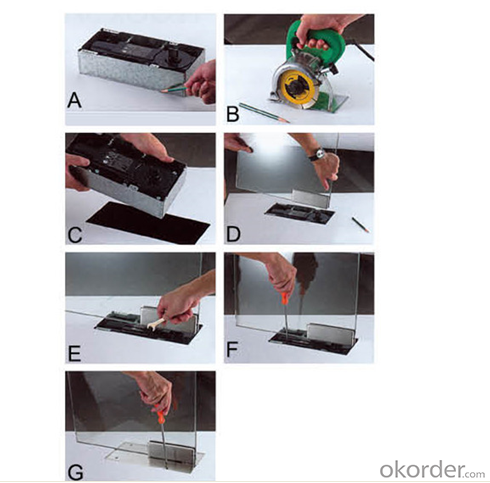

INSTALLATION STEPS

1. Draw lines and make floor spring pivot center and door-nip pivot coincide with each other.

2. Drill holes on the floor according to the instructions. The sizes of the holes must tightly match the floor spring.

3. Place the floor spring into the holes and position it.

4. Raise the door leaf installed with door-nip, and insert the floor spring pivot into the hole of the door leaf.

5. Adjust the screws at three directions. Make them vertical and the upper and lower pivot center coincide with each other.

6. Adjust the speed of door closing.

7. Put the decoration cover on the floor spring.

Package

Workshop

Testing Room

- Q: Is spring steel manganese steel?

- With wings are not necessarily the "angel", also may be "bird". Steel not containing Mn elements is called manganese steel. Manganese steel refers to those with high strength steel, mainly used for impact, friction and extrusion, mainly wear and tear.

- Q: The glass door spring is generally guaranteed for several years

- Quality and price are pretty much the same. Many other miscellaneous brands of spring can be guaranteed for five years, three years it is best to begin with a reliable brand

- Q: Stainless steel and spring steel hardness, who is hard?

- To sell the spring steel where seen relatively hard two pliers are very difficult to open

- Q: What kind of production equipment does spring factory usually have?

- Multi function forming machine, coil spring machine, 580 press spring machine, extension spring machine, etc.Small heat treatment is also needed

- Q: What's the manganese content of spring steel?

- Refer to Baidu Encyclopedia: in accordance with its manganese content is divided into general manganese content (mass fraction) (0.50%~0.80%), such as 65, 70, 85 and higher manganese content (mass fraction) (0.90~1.20%), such as 65Mn two categories.

- Q: What is an independent bagged spring?

- Independent bagged spring is a spring with non-woven package, barrel type design can prevent the spring friction and swinging or noise, no influence between spring, elastic energy in accordance with the size of individual expansion, different weight average and proper support of various parts of the body to keep the spine straight, make sleep more comfortable. Bagged spring than ordinary spring production process is more complicated, the cost is higher, so the price is slightly expensive. But human health is obviously.

- Q: The shop glass spring door is too tight, how to adjust?

- The spring of the stainless steel cover apart, there are 3 word brass wire, a label is in the middle of the elastic adjustment, Zuo Song left right tight, elastic, elastic, dextral (clockwise) that don't mix too much, a little bit, take it for a test drive, if you do not have the best mark pen in a gong wire above the mark, next to the two speed is adjustable,Note, the label ripped open, there will be no warranty, and all gongs silk must not be twisted out, only minor adjustments

- Q: Cold rolled coil spring spring and difference "

- The main production process is different, the compression spring as an example:The typical process of coil spring: blanking - end processing (rolled or forged flat) - heating - - - quenching - tempering spring roll grinding end - compressor (load - Test), shot peening (cleaning) - coating.Cold roll spring does not require heat treatment of material roll, point line process: rolling, annealing, stress to both ends of the surface grinding, (blast), (the whole school), (BKS), standing or forcing treatment, surface inspection and treatment.Coil spring is mainly used for rolling large spring, heating easily after twisting forming, springback is smaller, molding after quenching and tempering treatment.The cold coiling spring is directly coiled with spring steel wire, and the resilience is greater, and the winding tools need to consider the springback compensation amount and roll into the direct tempering process.

- Q: How to process Spring Steel

- Ha ha, friend,At first I thought it was a springFirst, you want to buy hot, or annealed spring steel, the standard number is GB/1222-2007< more than and 10 grades, including you 65 and 60 Si 2 A> Meng MengI'll probably help you figure it out. There are so many processes1 turning 2 milling machine processing openings 3 heat treatmentWell, I'm going to work, tooI hope my answer is of some use to you

- Q: How to distinguish between spring steel and stainless steel

- Stainless acid resistant steel, or stainless steel, is made up of two parts: stainless steel and acid resistant steel. In short, steel that resists atmospheric corrosion is called stainless steel, and steel resistant to chemical corrosion is called acid resistant steel. Spring steel is a quality carbon steel, but it can rust.

Send your message to us

Hydraulic Floor Hinge/ Door Closer/Floor Spring for Glass Door/Floor Hinge for Glass Door FS-7300

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords