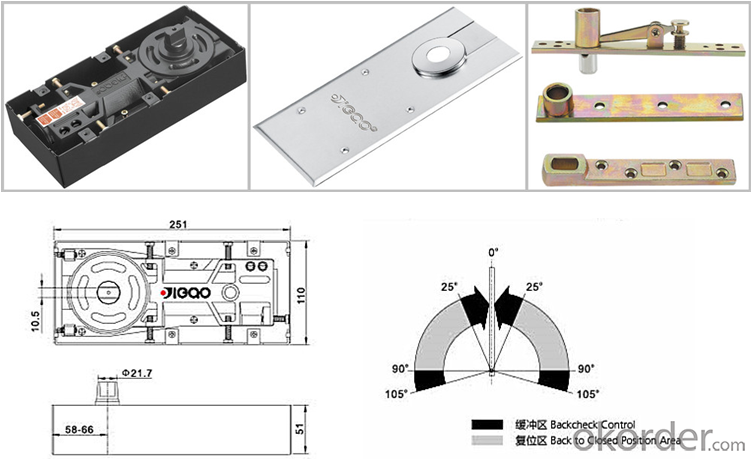

Hydraulic Door Closer /Floor Spring/Floor Hinge for Glass Door FS-75

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

INTRODUCTION

Floor Spring is used for glass door, and they can be used together with door clamp. Floor Spring can be opened with double sizes, and on this point, it is different from that of door closer, which can just be opened by one size. The key of technique lies on the loading seat under the main bearing, which decides the level of loading on the floor spring. Usually it can be opened from 300thousand or 1million times

FEATURES

u Applicable for glass doors, wooden doors and the glass doors of metal frame and wooden frame.

u Floor spring comply to EN 1154 and GB standard , and fire-rated EN1634 standard.

u Maximum 500000 cycles tested without damage or maximum 7 years guarantee.

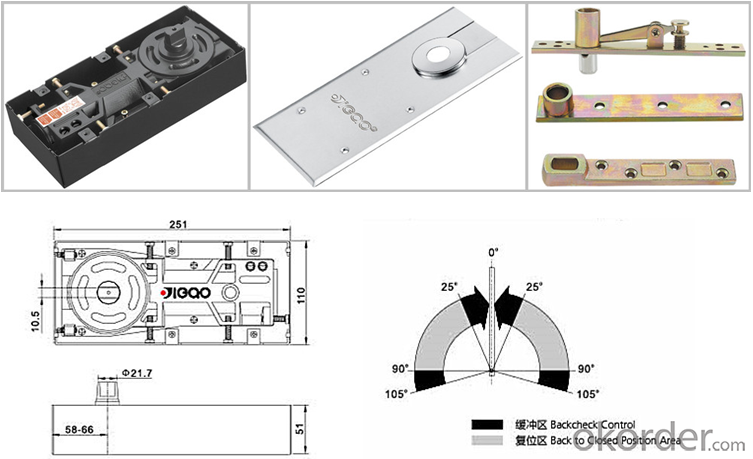

u Double ways opening with smoothly movement, hold-open at 90°.

u Closing speed and latching speed adjustable, latching point accurately at 0°

u Stainless steel cover plate, satin or mirror surface available.

u High quality casting iron floor spring body with 2 layers anti-rust coating.

u All spindle types available for different countries.

u Germany hydraulic machine oil and sealed rings, keep perfect working in cold temperature.

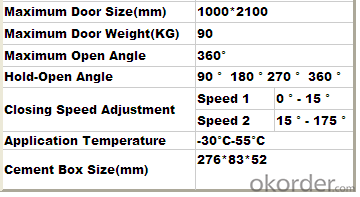

SPECIFICATION

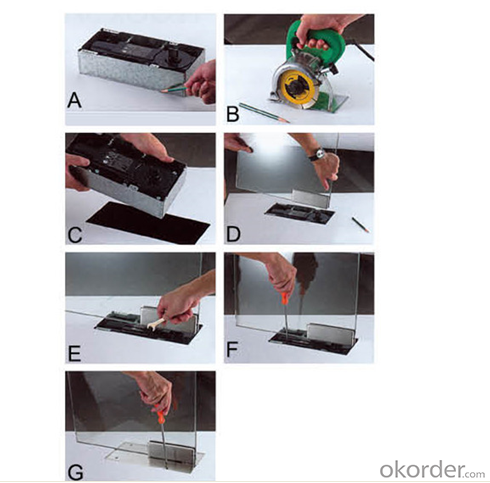

INSTALLATION STEPS

1. Draw lines and make floor spring pivot center and door-nip pivot coincide with each other.

2. Drill holes on the floor according to the instructions. The sizes of the holes must tightly match the floor spring.

3. Place the floor spring into the holes and position it.

4. Raise the door leaf installed with door-nip, and insert the floor spring pivot into the hole of the door leaf.

5. Adjust the screws at three directions. Make them vertical and the upper and lower pivot center coincide with each other.

6. Adjust the speed of door closing.

7. Put the decoration cover on the floor spring.

Package

- Q: The glass door spring is generally guaranteed for several years

- but once you change the maintenance fees are higher than the artificial spring spring price itself

- Q: Spring dynamometer and spring balance what is the difference

- Spring dynamometer and spring balance what is the differenceThis is a question of grade seven (junior one).You didn't answer all right. I found it on the Internet now:The size of the measurement tool called spring dynamometer, dynamometer is a commonly used dynamometer (including spring scale), the experiment is in common is the spring balance.Also, the spring scale is used to measure the force, not to measure the quality.

- Q: Can springs be used for support?

- The following individual ideas do not represent the bestFriction is bound to damage,Gaskets can be used to prevent direct friction between the spring and gear to lubricate, optimize wear and prolong life.

- Q: What's the manganese content of spring steel?

- The carbon content (mass fraction) of carbon spring steel is usually 0.62%~0.90%. In accordance with its manganese content is divided into general manganese content (mass fraction) (0.50%~0.80%), such as 65, 70, 85 and higher manganese content (mass fraction) (0.90~1.20%), such as 65Mn two categories.

- Q: I buy a spring made of 1.2mm steel wire from a hardware store that needs quenching

- First of all, you don't know whether the material is suitable for springs.Gas torch burning red spring, water or oil? The quenching temperature is not too good. It's too difficult to control: it can't be just right. Besides, tempering is necessary after quenching. Without tempering, of course, very brittle (hardened case), to the temperature above 400 degrees insulation for a period of time.If you're patient, experiment slowly, I hope. But if you're discouraged, it's hard to succeed.

- Q: How should we choose the spring material?

- Whether the spring is good or not is of great importance to the choice of the spring material. In general, selection of spring material, should take into account the load properties, spring force, various factors should be size, working conditions and price, etc.. Specific can follow the following principles: 1) in determining the shape and size of spring material, should be preferred dimensions behind national standards or standard stipulated, try to avoid using non standard materials. Although the spiral spring square or rectangular cross section material, the elastic deformation can be higher than, can make the small volume of the spring, for spring, in small space or under impact load but because of square or rectangular section material shortage, the price is higher, and the spring forming is difficult, so should be avoided. Ring section spring material diameter series see table 3-9. 2) the degree of cold plastic deformation of cold drawn spring materials is high. Most finished steel wires have reached the required mechanical properties when they leave the factory. The surface quality of the steel wire is high, and the manufacturing process of the spring is simple. For springs of medium or small spring or high fatigue life, the cold spring or cold drawn spring or steel wire or strip shall be selected as far as possible. Carbon spring steel wire (group I, group II, group II A, dish group) and important uses of 65Mn spring steel wire during the cold drawing process caused in large residual stress, the larger the size change after low temperature tempering, and thus affect the dimensional accuracy of the spring. For the bending radius of smaller tension and torsion spring, as well as smaller steel wire compression...

- Q: How to process Spring Steel

- Spring steel has excellent comprehensive performance, spring steel has excellent metallurgical quality (high purity and uniformity), good surface quality (strict control of surface defects and decarburization, precise shape and size).

- Q: What are the main functions of spring?

- The storage and release of energy, for example, the clock spring bolt spring

- Q: In short, in vibration and wave, it is not easy to make mistakes when we grasp the difference and relationship between "displacement" and "displacement relative to the balance position"

- In short, in vibration and wave, it is not easy to make mistakes when we grasp the difference and relationship between "displacement" and "displacement relative to the balance position"

- Q: Physics high school. Why does a spring fall to the lowest point and the acceleration a must be greater than the acceleration of gravity g ah. Seek expert

- For small spheres, the energy is conserved from the free fall to the ultimate spring compression equal to the maximum value of XMgX=0.5kX^2 (this formula is obtained by integration, do not know if you have no calculus)Calculate X=2mg/k, then the lowest point is the resultant force of the ball is kX-mg=2mg-mg=mg, in the direction of acceleration, the size is exactly equal to GIf the ball is considered to fall from high, then the energy conservation before it converts the energy of the potential energy into springs is naturally more, and the acceleration of the lowest point ball is greater than g

Send your message to us

Hydraulic Door Closer /Floor Spring/Floor Hinge for Glass Door FS-75

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords