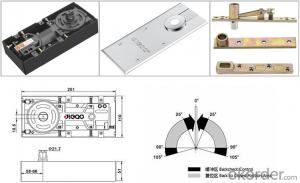

Hydraulic Floor Hinge/ Door Closer/Floor Spring for Glass Door/Floor Hinge for Glass Door FS-84

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

INTRODUCTION

Floor Spring is used for glass door, and they can be used together with door clamp. Floor Spring can be opened with double sizes, and on this point, it is different from that of door closer, which can just be opened by one size. The key of technique lies on the loading seat under the main bearing, which decides the level of loading on the floor spring. Usually it can be opened from 300thousand or 1million times

FEATURES

u Applicable for glass doors, wooden doors and the glass doors of metal frame and wooden frame.

u Floor spring comply to EN 1154 and GB standard , and fire-rated EN1634 standard.

u Maximum 500000 cycles tested without damage or maximum 7 years guarantee.

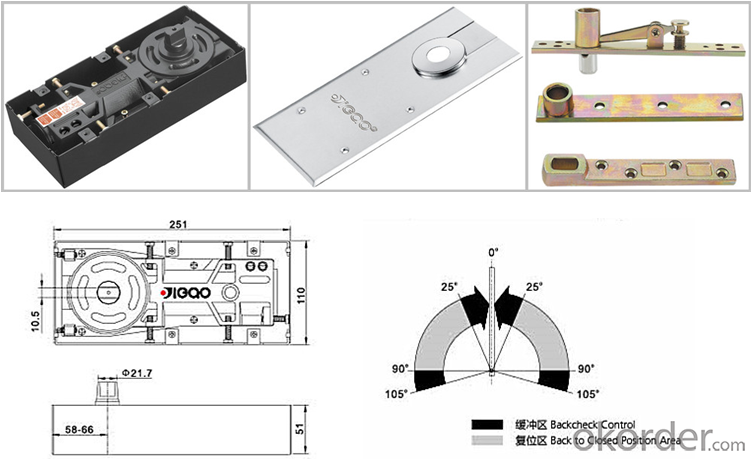

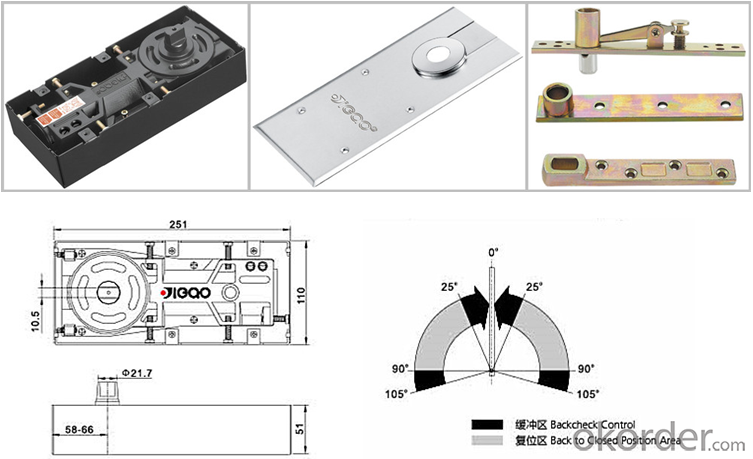

u Double ways opening with smoothly movement, hold-open at 90°.

u Closing speed and latching speed adjustable, latching point accurately at 0°

u Stainless steel cover plate, satin or mirror surface available.

u High quality casting iron floor spring body with 2 layers anti-rust coating.

u All spindle types available for different countries.

u Germany hydraulic machine oil and sealed rings, keep perfect working in cold temperature.

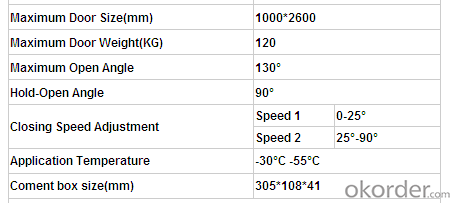

SPECIFICATION

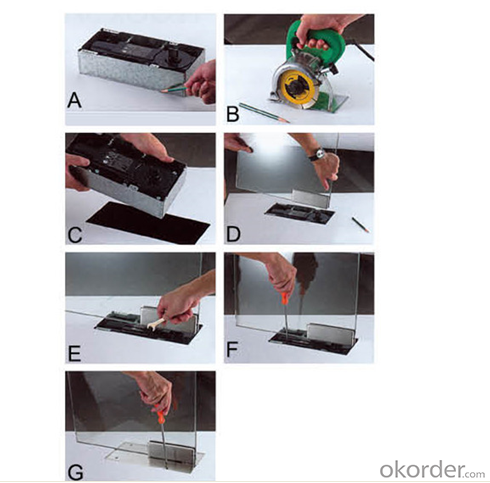

INSTALLATION STEPS

1. Draw lines and make floor spring pivot center and door-nip pivot coincide with each other.

2. Drill holes on the floor according to the instructions. The sizes of the holes must tightly match the floor spring.

3. Place the floor spring into the holes and position it.

4. Raise the door leaf installed with door-nip, and insert the floor spring pivot into the hole of the door leaf.

5. Adjust the screws at three directions. Make them vertical and the upper and lower pivot center coincide with each other.

6. Adjust the speed of door closing.

7. Put the decoration cover on the floor spring.

Package

Workshop

Testing Room

- Q: The glass door spring is generally guaranteed for several years

- but once you change the maintenance fees are higher than the artificial spring spring price itself

- Q: Want to practice how to use pectoral muscle spring expander

- The most simple way you can lie on the bed or on the floor and chest stretching is very effective and pay attention to more, so as not to hurt the small set of muscles.It takes at least one month to bear fruit

- Q: What's the spring material to?

- There are many kinds of spring steel, the most commonly used are 65Mn and 60Si2Mn.

- Q: What kind of material does spring have?

- 65MnSpring steel belongs to the mechanical structure steel; according to the quality grade, it belongs to the special quality steel, that is to say, in the process of production, it is necessary to strictly control the quality and performance of the steel.

- Q: What is flat steel? Plain carbon flat steel? Spring flat steel

- Flat refers to the width 12-300mm, thickness 4-60mm, cross section is rectangular in shape and with a blunt edge of steel. Plain carbon flat steel refers to carbon content of 0.06-0.22% flat steel. The spring flat steel refers to the flat steel with good elastic deformation ability.Flat steel can be finished steel, or can be used as the blank of welded pipe and thin slab for laminated sheet rolling. Main application: flat steel is used as a material, used for making iron, tools and machinery parts, and used as frame structures and escalators for buildings.

- Q: What's the manganese content of spring steel?

- Refer to Baidu Encyclopedia: in accordance with its manganese content is divided into general manganese content (mass fraction) (0.50%~0.80%), such as 65, 70, 85 and higher manganese content (mass fraction) (0.90~1.20%), such as 65Mn two categories.

- Q: I buy a spring made of 1.2mm steel wire from a hardware store that needs quenching

- It may be that the wire itself is not made of spring.The main performance requirements of spring steel are high strength and high yield limit and fatigue limit, so spring steel has higher carbon content. However, the hardenability of carbon steels is poor, so alloy steels must be used for springs with larger cross sections. The major alloying elements in alloy spring steels are silicon and manganese. They can increase hardenability and yield strength of steel.Carbon steel is used for spring with smaller diameter, and the process is mostly cold drawing, such as 65#, 75#, 85#.The diameter is a little big, and the spring produced by thermoforming process adopts 60Si2Mn, such as automobile leaf spring and buffer spring of railway vehicle.For high stress important spring can use 50CrV, commonly used in advanced sedan leaf spring, engine valve spring, etc..Other spring steel materials include: 65Mn, 50CrMn, 30W4Cr2V, etc..1.2mm diameter is not fine, so it is not hardened, it is too hard to break.

- Q: What are the main functions of spring?

- There are many kinds of spring, and the spring is mainly divided into four kinds: stretching spring, compression spring, torsion spring and bent spring. If in accordance with the spring shape and can be divided into helical springs, disc springs, ring spring, plate spring, spring etc.. The basic types of springs are listed in the table. Air springs.

- Q: In short, in vibration and wave, it is not easy to make mistakes when we grasp the difference and relationship between "displacement" and "displacement relative to the balance position"

- In short, in vibration and wave, it is not easy to make mistakes when we grasp the difference and relationship between "displacement" and "displacement relative to the balance position"

- Q: The glass door spring is broken. How much would it cost to change it?

- Replace the ground spring, the price of the earth spring itself, but also part of the labor costs, after all, it is very expensive. Land springs in general, if used in general, that is, about 150, but with labor costs, usually around 80. Specific prices should be based on your actual situation, you and the master speak.

Send your message to us

Hydraulic Floor Hinge/ Door Closer/Floor Spring for Glass Door/Floor Hinge for Glass Door FS-84

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords