Power Spring by Rolled Stainless Steel Ribbon

- Loading Port:

- Nansha

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 Piece/Pieces pc

- Supply Capability:

- 151000000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Power Spring

1, over 10 years OEM experience

2, can pass Salt Spray Test

3, 3,000,000 pcs capacity/month

4, No MOQ Limit

5, Free sample

Power Spring

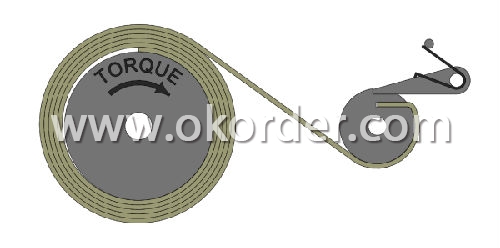

The constant force spring is made by the rolled stainless steel ribbon, through a particular machine to stereotypia the high strength steel

ribbon, when it is straightened by an external force , the constant force spring will roll by naturally and then generate elastic force. Thereby,

the object can go back to the appionted original place.

Comparing with the traditional line spring, the advantage of the constant force spring is: it keeps particular elastic force during the route, and

route of the prestressing is short, that is say, we can get the necessary elastic force with a shorter route, the original length is smaller than the

line spring, unlimited route.

Prodution Scope:

1) Width: 2~80MM

2) Thickness: 0.08~0.7 MM

3) Length: according to your needs

4) Material: Stainless steel, Carbon Steel

5) Carton Size: 50x35x21CM / 35x25x17.5CM

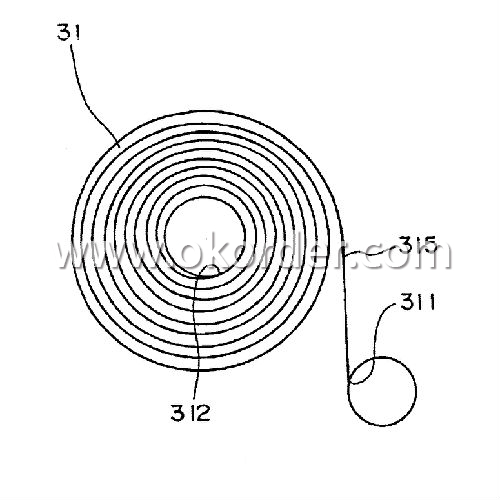

How the Power Spring Works?

Application of Power Spring:

1) height adjustment of LCD & Fan

2) shelves and display racks in megastore

3) curtain , door and window

4) gas nail gun and book sewer

5) motor carbon brushes

please send us below details, and we will feedback to you with price within one day:

1) material

2) size ( thickness, length, width)

3) maximum outside diameter or minimun inside diameter

4) quantity

5) drawings or sample

Our Packaging Workshop

- Q: The glass door spring is generally guaranteed for several years

- ,expect a warranty to ensure the quality is not very reliable.

- Q: Want to practice how to use pectoral muscle spring expander

- If your strength is not enough, a chest start even more difficult, not easy to do it.It is recommended that you should not rely solely on the chest muscle training, according to their ability, to start from the first push ups. Practice to a certain extent to practice chest.If possible, the best way is to do chest push arms parallel flexion, but more difficult.The best chest group 20, a group is appropriate.

- Q: Hydraulic diagram of the one-way valve has two kinds of drawing, with a spring, without a spring, what is the difference between automatic reset function is not? Without a spring, it will not be repeated

- The simplified method of drawing without springs is the same

- Q: What is spring pressure and height?

- Press the compression spring to the point where each circle is tight. Press it and press it high

- Q: What is flat steel? Plain carbon flat steel? Spring flat steel

- Section steel is one of the four major steel products (plate, tube, mould, wire). According to the section shape, the section steel is divided into simple section steel and complex section steel (deformed steel). The former refers to the steel, round steel, flat steel, angle steel, six angle steel; the latter refers to the I-beam, channel steel, steel, steel, steel frame bending etc.. Square, square section steel, cold and hot points in two; length of hot-rolled square steel 5-250mm; cold drawn steel length 3-100mm. Round - round section steel, hot, forged and drawn three, hot-rolled bar diameter 5-250mm, which 5-9mm used as drawing steel wire material, called wire; due to disk supply is also called hot rod. Forged round steel is thicker, used as axle billet. Cold drawn round steel diameter 3-100 mm, high dimensional accuracy. Flat - width 12-300mm, thickness 4-60mm, cross section is rectangular and with pure edge of steel. Flat steel can be finished steel, or can be used as the blank of welded pipe and thin slab for laminated sheet rolling. Angle steel -- two kinds of grade angle steel and unequal angle steel. The dimension of angle iron is expressed by the dimension of the length of side and the thickness of edge. The standard angle steel, usually produced, is 2-20, which is the centimeter side length. Such as 5 equal angles, that is, the length of 5cm (50mm) angle steel. The same horn steel often has 2-7 different edge thickness. Steel bars are not the classification of profiled steel. First, the basic concepts of ferrous metals, steels and nonferrous metals are briefly introduced before introducing the classification of steels, ferrous metals, steels, and nonferrous metals. 1. Ferrous metals are alloys of iron and iron. Such as steel, pig iron, iron alloy, cast iron and so on. Steel and pig iron are both...

- Q: What kind of spring has the best performance?

- The length of the spring, with a number of differences between the spring, will affect the product intensity consistency.

- Q: How should we choose the spring material?

- Whether the spring is good or not is of great importance to the choice of the spring material. In general, selection of spring material, should take into account the load properties, spring force, various factors should be size, working conditions and price, etc.. Specific can follow the following principles: 1) in determining the shape and size of spring material, should be preferred dimensions behind national standards or standard stipulated, try to avoid using non standard materials. Although the spiral spring square or rectangular cross section material, the elastic deformation can be higher than, can make the small volume of the spring, for spring, in small space or under impact load but because of square or rectangular section material shortage, the price is higher, and the spring forming is difficult, so should be avoided. Ring section spring material diameter series see table 3-9. 2) the degree of cold plastic deformation of cold drawn spring materials is high. Most finished steel wires have reached the required mechanical properties when they leave the factory. The surface quality of the steel wire is high, and the manufacturing process of the spring is simple. For springs of medium or small spring or high fatigue life, the cold spring or cold drawn spring or steel wire or strip shall be selected as far as possible. Carbon spring steel wire (group I, group II, group II A, dish group) and important uses of 65Mn spring steel wire during the cold drawing process caused in large residual stress, the larger the size change after low temperature tempering, and thus affect the dimensional accuracy of the spring. For the bending radius of smaller tension and torsion spring, as well as smaller steel wire compression...

- Q: Cold rolled coil spring spring and difference "

- The main production process is different, the compression spring as an example:The typical process of coil spring: blanking - end processing (rolled or forged flat) - heating - - - quenching - tempering spring roll grinding end - compressor (load - Test), shot peening (cleaning) - coating.Cold roll spring does not require heat treatment of material roll, point line process: rolling, annealing, stress to both ends of the surface grinding, (blast), (the whole school), (BKS), standing or forcing treatment, surface inspection and treatment.Coil spring is mainly used for rolling large spring, heating easily after twisting forming, springback is smaller, molding after quenching and tempering treatment.The cold coiling spring is directly coiled with spring steel wire, and the resilience is greater, and the winding tools need to consider the springback compensation amount and roll into the direct tempering process.

- Q: How to distinguish between spring steel and stainless steel

- Mainly depends on the performance of spring steel, good elasticity, stainless steel toughness. The color should be slightly white stainless steel. Spring steel is easy to rust, with a little salt a day you can see the stainless steel does not rust.

- Q: Physics high school. Why does a spring fall to the lowest point and the acceleration a must be greater than the acceleration of gravity g ah. Seek expert

- According to the conservation of mechanical energy, the object should be a free fall motion at the upper end of the spring

1. Manufacturer Overview

| Location | Guangdong, China |

| Year Established | 1992 |

| Annual Output Value | Above US$ 10 Million - US$ 50 Million |

| Main Markets | North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe, Central America |

| Company Certifications | ISO 9001:2000 ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shenzhen |

| Export Percentage | 60% - 80% |

| No.of Employees in Trade Department | 301 - 500 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | above 2000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Power Spring by Rolled Stainless Steel Ribbon

- Loading Port:

- Nansha

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 Piece/Pieces pc

- Supply Capability:

- 151000000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords