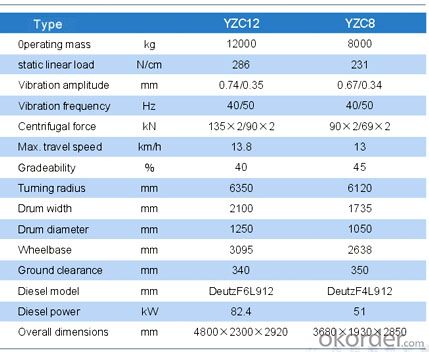

Hydraulic Double Drum Vibratory Rollers YZC12

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 35 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hydraulic double drum vibratory rollers are manufactured according to international advanced technology and by use of imported main components abroad, suitable for compaction of various stabilized soils, bituminous concrete and rolling cement concrete (RCC) on road surface construction, also for compaction of road base course,which are universal compaction equipments for high-class highway, airport, harbors, dams, municipal road and industrial ground.

Imported Deutz air-cooled diesel engine with excellent performance.

Hydrostatic all-drum travel drive directly by slow speed high torque hydraulic motors at two range infinitely variable speeds.

Dual frequency and amplitudes vibration system with imported piston pump and motors.

Center articulated steering with crabwalk unit for flexible maneuverability.

Integrated multi-disc wet brake with oil-cutoff braking for reliable safety.

Comfortable and spacious operator's cab with dual steering wheels and seats for convenient operations.

Electric power sprinkler system with large capacity reinforced polyethylene water tank.

Welcome you to visit our factory in China. Anything we can do, please feel free to let us know. We are sure your inquiries will get our prompt attention.

- Q: What's the BMW roller BW203AD-4?

- Parameter configuration of BMW BW203AD-4 rollerOverall sizeTotal width (mm) 2135EngineDeutz models DeutzMass load parameterQuality of work with cab (kg) 13000DeutzN. A. & Cie. Otto originally founded in 1864 in Cologne DEUTZ, is now the longest history in the world, the world's leading independent manufacturer of engine. As a whole series of engine experts, DEUTZ provides power range from 25KW to 520KW water-cooled and air-cooled engine, can be widely used in engineering machinery, generators, agricultural machinery, commercial vehicles, railway locomotives and ships, and applied to various professional use.Deutz company in more than 130 countries have 9 distribution companies in the world, 9 sales offices and 16 service centers

- Q: XCMG 303 tire roller engine type

- The road roller belongs to equipment in construction machinery category, widely used in Embankment Compaction of highway, railway, airport runway, dam, stadium and other large projects, can crush sand, semi viscous soil, the stability of subgrade soil and asphalt concrete pavement. The utility model is suitable for various compacting operations of the static pressure roller by the gravity action of the machine itself, so that the compacted layer is permanently deformed and compacted. It is divided into two types: steel wheel type and tyre type. Grinding wheel grinding, grinding groove structure light and kneading etc.. The most common application of light milling is mainly used for compaction of surface layer of road vibratory roller. With mechanical or hydraulic transmission, the utility model can concentrate the compacted part of the protruding part, and has high compaction and smoothness, and is suitable for the compaction operation of the asphalt pavement.

- Q: How to get a motorcycle driver's license?

- There is no special roller driving license, driving license requires the use of B2, as well as special work roller operation certificate certificate, by the state production safety supervision and Management Bureau issued a "special operations People's Republic of China operating license" certificate, the national general certificate.

- Q: What is the concept of the static line pressure of roller?

- Striking force: the vibratory roller's pressure on the ground during vibrationNominal amplitude: the magnitude of a vibratory wheel that rises vertically and downward when vibrating

- Q: What are the classification methods of vibratory rollers?

- Double steel roller drive is divided into two driving double vibration, double drive single vibration (walking drive, vibration compaction)There may be other, too. This is a more conventional classification.

- Q: What is a roller?

- The road belongs to the road equipment in construction machinery category, widely used in Embankment Compaction of highway, railway, airport runway, dam, stadium and other large projects, can crush sand, semi viscous soil, the stability of subgrade soil and asphalt concrete road surface

- Q: Will the Apocalypse Tank be pressurized back?

- but also not explosion damage, the armor is even more powerful, not simply rely on the weight can be crushed,

- Q: What do you mean by "380/275" in the vibratory force (kN) of vibratory roller?

- Or what it means.There are two modes of operation for a vibratory roller. The first mode produces the exciting force of 380KN while the other model produces the exciting force of 275KN.

- Q: The working principle of roller

- Freon compression, using compression method Freon liquefaction, heat release,The liquid Freon enters the air conditioner, the indoor unit or the refrigerator to vaporize and absorb heat and cool downThe vaporized Freon enters the compressor and compresses and liquefy, giving off heat, thus reciprocating

- Q: I have never touched, very strange, roller okay? By the way, under the drive must pay attention to, to the older generation back to 150Friends to learn to drive roller, I have never touched, very strange, roller okay? By the way, we must pay attention to the following road roller

- Do you want to open what is the single roller, Ganglun repair pavement or asphalt pavement temperature, double rigid gear

Send your message to us

Hydraulic Double Drum Vibratory Rollers YZC12

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 35 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords