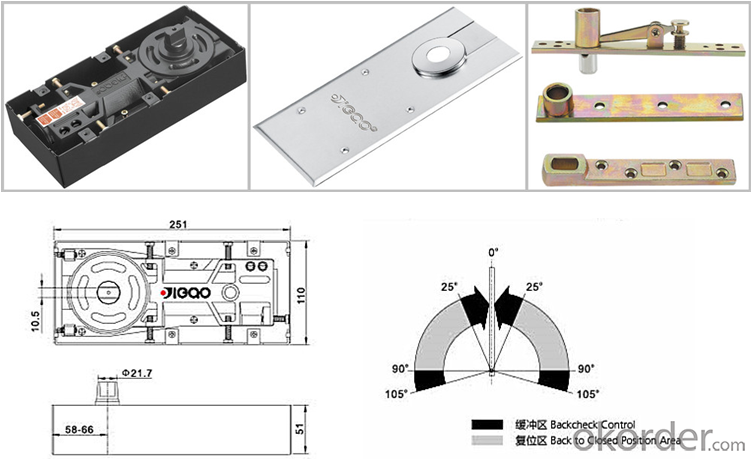

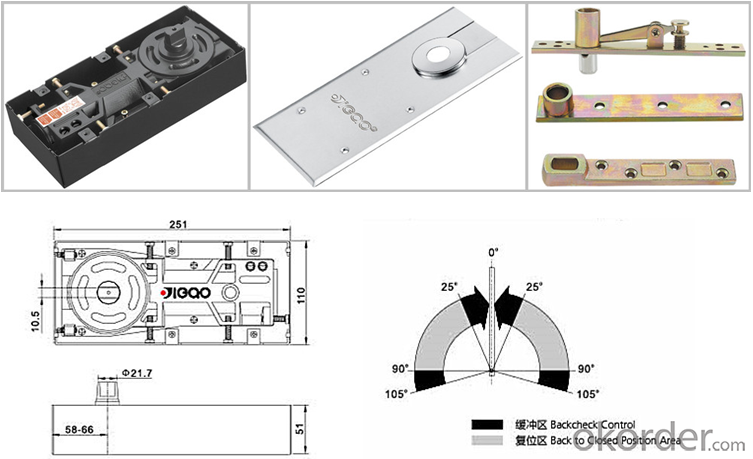

Hydraulic Door Hinge /Floor Spring/Floor Hinge for Glass Door FS-75

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

INTRODUCTION

Floor Spring is used for glass door, and they can be used together with door clamp. Floor Spring can be opened with double sizes, and on this point, it is different from that of door closer, which can just be opened by one size. The key of technique lies on the loading seat under the main bearing, which decides the level of loading on the floor spring. Usually it can be opened from 300thousand or 1million times

FEATURES

u Applicable for glass doors, wooden doors and the glass doors of metal frame and wooden frame.

u Floor spring comply to EN 1154 and GB standard , and fire-rated EN1634 standard.

u Maximum 500000 cycles tested without damage or maximum 7 years guarantee.

u Double ways opening with smoothly movement, hold-open at 90°.

u Closing speed and latching speed adjustable, latching point accurately at 0°

u Stainless steel cover plate, satin or mirror surface available.

u High quality casting iron floor spring body with 2 layers anti-rust coating.

u All spindle types available for different countries.

u Germany hydraulic machine oil and sealed rings, keep perfect working in cold temperature.

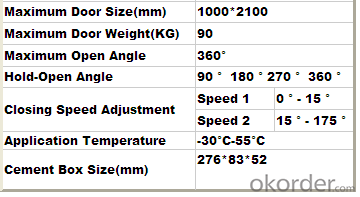

SPECIFICATION

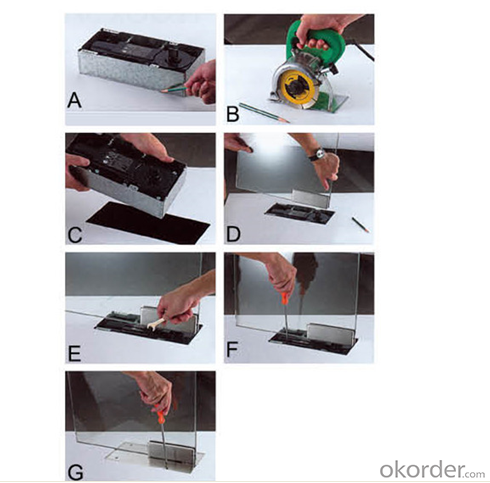

INSTALLATION STEPS

1. Draw lines and make floor spring pivot center and door-nip pivot coincide with each other.

2. Drill holes on the floor according to the instructions. The sizes of the holes must tightly match the floor spring.

3. Place the floor spring into the holes and position it.

4. Raise the door leaf installed with door-nip, and insert the floor spring pivot into the hole of the door leaf.

5. Adjust the screws at three directions. Make them vertical and the upper and lower pivot center coincide with each other.

6. Adjust the speed of door closing.

7. Put the decoration cover on the floor spring.

- Q: Buffer spring buffer for automobile

- Rubber buffer also known as buffer, buffer, buffer block, rubber shock absorber, shock absorber rubber and so on, the most correct name is "automobile spring cushion", is the name of Car Spring Buffer Retainer English, 1 luxury cars with a buffer principle significantly improve the damping performance of vehicles.

- Q: Want to practice how to use pectoral muscle spring expander

- The most simple way you can lie on the bed or on the floor and chest stretching is very effective and pay attention to more, so as not to hurt the small set of muscles.It takes at least one month to bear fruit

- Q: Stainless steel and spring steel hardness, who is hard?

- Hardness is checked by indentation, not by pliers.Stainless steel, of course

- Q: Hydraulic diagram of the one-way valve has two kinds of drawing, with a spring, without a spring, what is the difference between automatic reset function is not? Without a spring, it will not be repeated

- The simplified method of drawing without springs is the same

- Q: What are the categories of springs?

- The coil spring, the torsion spring, is a spring that bears torsional deformation, and its working part is tightly wound into a spiral shape. The torsion spring end is made of twisted arms of various shapes rather than rings.

- Q: What's the spring material to?

- 65Mn, 55Si2Mn, 60Si2Mn, 50CrVA, 75, 85, 55CrMnA, 60Si2CrVA, 60Si2MnA, 70, 65, 50CrMo, 55SiMnMoVNb, 60SiMnMoA, 65Si2MnWA, 70Si3MnA, and so on

- Q: Can springs be used for support?

- The following individual ideas do not represent the bestFriction is bound to damage,Gaskets can be used to prevent direct friction between the spring and gear to lubricate, optimize wear and prolong life.

- Q: What kind of spring has the best performance?

- Spring surface scars, spring surface injury to use a magnifying glass to see, manufacturers generally use 300 times electronic magnifying glass, spring 300 times, see the injury, the impact on life is very big.

- Q: Cold rolled coil spring spring and difference "

- Difference: the main annealing time is different. In the production process, is the first volume of coil spring and annealing, and spring is the first cold roll annealing, and then roll. Similar to cold rolling and hot rolling of steel.Note: spring making methodProduction method of cold rolled coil spring: to stress annealing, end surface grinding, (blast), (the whole school), (BKS), standing or forcing treatment, surface inspection and treatment.Production method of coil spring: blanking, end processing (rolled or forged flat), heating, coiling, quenching, tempering, grinding end to compression to (load test), shot peening (cleaning), coating.

- Q: Is the car short spring good?

- Because of the short spring, the fluctuation of the whole suspension system is too small, and the damping of the shock absorber system changes too directly, so that the comfort of the vehicle will decrease. That means it's going to be pretty bumpy.

Send your message to us

Hydraulic Door Hinge /Floor Spring/Floor Hinge for Glass Door FS-75

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords