Compression Spring with Zinc, Tin, Nickel

- Loading Port:

- Nansha

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 Piece/Pieces pc

- Supply Capability:

- 300000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

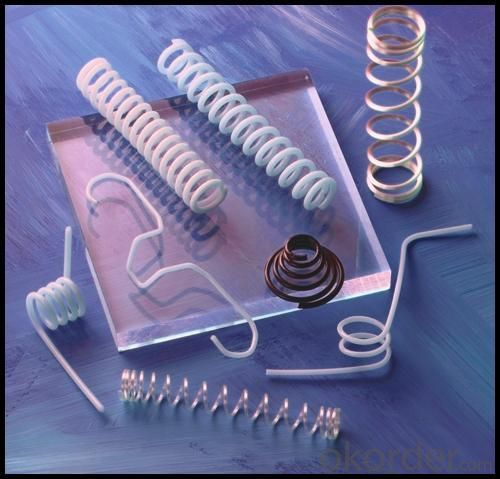

Specifications of Compression Spring

1. high quality

2.very competitive price.

3.timely delivery

4.good service after-sale

Compression spring

high carbon steel compression spring,stainless steel compression spring,

all kinds of compression spring,compression spring

manufacturer,high quality compression spring,custom compressions spring.

China compression spring.xiamen compression spring

Material | Spring Steel |

| Stainless Steel | |

| Low Carbon Steel | |

| High Carbon Steel | |

| Music Wire / Piano Wire | |

| Galvanized Steel | |

| Hard Drawn | |

| Non-ferrous Metals | |

| Surface Finish | Zinc/ Tin/ Nickel/ Chrome Plating, Black Oxide, Color Painted, PVC/ Powder Coating, |

| Shot Blasting, Anodizing, Plain, Polishing, Passivate, Electorolysis | |

| Wire Diameter | 0.1 ~ 8.0 mm |

| 0.004 ~ 0.315 in | |

| Outer Diameter | 4.0 ~ 80 mm |

| 0.157 ~ 3.15 in | |

| Direction of Wind | Left Hand |

| Right Hand | |

| Optional | |

| Packaging Detail: | inner packing: PE bag, outer packing: corrugated carton or box due to customer's requirement |

Packaging & Delivery

Packaging Detail: inner packing: PE bag,

outer packing: corrugated carton or box due to customer's requirement

Delivery Detail: 5-7days

- Q: The glass door spring is generally guaranteed for several years

- Quality and price are pretty much the same. Many other miscellaneous brands of spring can be guaranteed for five years, three years it is best to begin with a reliable brand

- Q: Want to practice how to use pectoral muscle spring expander

- Every day until the last time I can not pull itFull pullExercise is a long process

- Q: Stainless steel and spring steel hardness, who is hard?

- To sell the spring steel where seen relatively hard two pliers are very difficult to open

- Q: Can springs be used for support?

- The following individual ideas do not represent the bestFriction is bound to damage,Gaskets can be used to prevent direct friction between the spring and gear to lubricate, optimize wear and prolong life.

- Q: How to choose spring steel material?

- In determining the cross-section shape and size of spring materials, priority should be given to rejection of the national standards or ministerial standards for size specifications, as far as possible to avoid the use of non-standard specifications of materials. Although the spiral spring square or rectangular cross section material, the elastic deformation can be higher than, can make the small volume of the spring, for spring, in small space or under impact load but because of square or rectangular section material shortage, the price is higher, and the spring forming is difficult, so should be avoided. Ring section spring material diameter series see table 3-9.

- Q: What kind of spring has the best performance?

- Spring outside diameter, the same spring at both ends of the outer diameter and the middle of the outer diameter is not the same, unlike the spring, the force has a slight impact. The same batch is very different from each other, indicating that the machining accuracy is very poor.

- Q: Is the car short spring good?

- Because of the short spring, the fluctuation of the whole suspension system is too small, and the damping of the shock absorber system changes too directly, so that the comfort of the vehicle will decrease. That means it's going to be pretty bumpy.

- Q: How to process Spring Steel

- Spring steel has excellent comprehensive performance, spring steel has excellent metallurgical quality (high purity and uniformity), good surface quality (strict control of surface defects and decarburization, precise shape and size).

- Q: What are the main functions of spring?

- The storage and release of energy, for example, the clock spring bolt spring

- Q: How to distinguish between spring steel and stainless steel

- With saline in two days to put a steel can see rust is a way (can, for 304 stainless steel 201 stainless steel will rust, only less); another way is to put the two kinds of steel can see the reaction is on spring steel in dilute sulfuric acid, oxalic acid, not the reaction or reaction of small stainless steel.

1. Manufacturer Overview

| Location | Suzhou, China |

| Year Established | 2001 |

| Annual Output Value | more than US$ 5 Million |

| Main Markets | North America, South America, Eastern Europe, Southeast Asia, Africa, Mid East, Eastern Asia, Western Europe |

| Company Certifications | ISO/TS 16949; ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | About 170 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | About 35,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Compression Spring with Zinc, Tin, Nickel

- Loading Port:

- Nansha

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 Piece/Pieces pc

- Supply Capability:

- 300000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords