Mould Spring with free design

- Loading Port:

- Ning Bo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000Pieces pc

- Supply Capability:

- 100000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

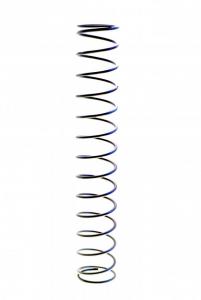

The Specifications of The Mould Springs

Product Name | Compression mould spring | Supply Ability | 900000000PCS | ||

| Wire diameter | 0.08mm~10.0mm | Type of shipping | By sea/air/DHL/Fedex/UPS etc | ||

| Quality certification | ISO9001:2008.SGS,the French | Payment term | L/C,T/T,D/A,D/P,Western union,Money Gram,Paypal | ||

| BV authentications | |||||

| The scale of Hershey spring | About 6000 suqare meters | Employee numbers | About 100.and our group are becoming larger | ||

| Industry Experience | Over 21 years' experience in the spring industry. | ||||

Mould Spring Production and Manufacturing

1.Our engineers are eager to help provide the most dependable mould

spring for your applications. Our company is a mould spring

manufacturer that you can depend on to deliver high quality mould

spring with speedy lead times

2.Specialiaze in mould spring .your inquiries will get prompt reponse

within 24 hours.

3.Free design all kind of non-standard mould spring as you requested.

4.Specification: 6X10mm ---70X500mm

5.Paint:environmental protection electrophore

Mould Spring:Use of attention for mould spring

Choose right mould spring or will distortion and reduce service life.

Can’t have gap between upper plate and mould spring or will distortion and rupture.

When free length of moudl spring is 4 times to outer diameter ,please use guide rod shield to protect service life.

Can't use it for anything except compression .

Please use it on the mould.

When the lower plate parallelism is not well, high stress will happen and cause transformation and rupture .

It must be have some preloading when put mould spring on the mould . preventing mould Bear impact load and cause fatigue damage.

Install and valid service condition

>When Coil Spring install the hole of bottom without leader ,the deep of hole must be more than two rings than mould springs.

>when mould spring install with leader ,length of leader must be higher than length of mould spring

>.Close state (stroke limit) is reference dimension ,Pls do not use if more than 300000 times or it will be bending and failure.

>When installing, preloading is one over ten or more of the compression. When cope plate use with gap .will cause mould spring bending or scrap.

Service condition:

1. Allowed temperature range for mould spring

TF.TL.TM.TH.TB.TR.TY : 80°C--30°C

Higher than these temperature ,you should customize.

In practice,when temperature higher than above. Mould spring will be scrap ,bending and etc. or use based on technicist’s guide .

2.Don’t use mould spring on high temperature and wet ,or mould spring will be scrap ,bending and rustiness.

Packaging and Transportation

Our factory of Mould Springs

- Q: Buffer spring buffer for automobile

- The automobile spring buffer adopts the cushion principle to reduce the vibration produced by the vehicle during the running, and increase the comfort of the car. When the vehicle is equipped with a spring buffer, the problem of the spring of the shock absorber is effectively solved, the performance of the shock absorber is recovered, and the shock absorber and the suspension system are also protected, and the oil seal of the damping core is avoided. As long as the quality is good and the car to pick their own spring buffer models, can save at least 3 sets of shock absorber overhead, and a shock absorber to several hundred dollars or a thousand dollars, the long term of the owner is indeed a big burden. The new car spring buffer is a buffer of urethane material, not only simple and easy installation, no looseness of vehicle any screws, can make the body up 3 5cm, recovery of the original body height, improve the stability of road safety through deceleration and brake, greatly reduce the fatigue feeling after. The car cushion on the market are made of urethane material, suggest that you choose the buffer glue to the regular manufacturers purchase, on the market there are many inferior or three villages are often unable to get some of the results, some even hurt the shock absorber, shorten the service life of the damping rubber. My friend used Jinke rubber buffer for years should be full, very good quality.

- Q: Hydraulic diagram of the one-way valve has two kinds of drawing, with a spring, without a spring, what is the difference between automatic reset function is not? Without a spring, it will not be repeated

- Most of the one-way valves are springs, but the springs are usually soft and the flow resistance can be neglected. Normally, a one-way valve with a pressure of more than 0.3 MPa draws a spring mark on the hydraulic schematic.

- Q: Spring dynamometer and spring balance what is the difference

- The principle is similar, but the uses are somewhat different

- Q: What's the spring material to?

- 1, with alloy spring steel, respectively, there are several kinds of steel: 55Si2Mn or 50CrVA and 30W4Cr2VA, these alloy spring steel;2, manufacturing process:Coil the machine first into the spring and then proceed with the proper heat treatment process to get the spring you need.

- Q: What is flat steel? Plain carbon flat steel? Spring flat steel

- It is the name of a steel produced according to a certain specification, such as angle steel, channel steel, etc. ordinary carbon flat steel and spring flat steel are different materials used to make flat steel

- Q: I buy a spring made of 1.2mm steel wire from a hardware store that needs quenching

- First of all, you don't know whether the material is suitable for springs.Gas torch burning red spring, water or oil? The quenching temperature is not too good. It's too difficult to control: it can't be just right. Besides, tempering is necessary after quenching. Without tempering, of course, very brittle (hardened case), to the temperature above 400 degrees insulation for a period of time.If you're patient, experiment slowly, I hope. But if you're discouraged, it's hard to succeed.

- Q: How to choose spring steel material?

- Spring steel is selected on the basis of the section size of the spring, such as high carbon steel 65, suitable for production in the spring of 12 ~ 15mm under section 60CrMnA, suitable for the production of spring and the car less than 50mm in diameter with heavy-duty spring. The 30W4Cr2VA is used to make heat-resistant spring for work below 500 degrees centigrade. Generally, hot forming springs are generally quenched and tempered at moderate temperature to obtain a structure with a maximum elastic limit and fatigue properties

- Q: Cold rolled coil spring spring and difference "

- Difference: the main annealing time is different. In the production process, is the first volume of coil spring and annealing, and spring is the first cold roll annealing, and then roll. Similar to cold rolling and hot rolling of steel.Note: spring making methodProduction method of cold rolled coil spring: to stress annealing, end surface grinding, (blast), (the whole school), (BKS), standing or forcing treatment, surface inspection and treatment.Production method of coil spring: blanking, end processing (rolled or forged flat), heating, coiling, quenching, tempering, grinding end to compression to (load test), shot peening (cleaning), coating.

- Q: How to process Spring Steel

- The available oxygen converter furnace and open hearth furnace or general production of spring steel; high quality spring steel or better quality with special properties, furnace or vacuum refining furnace. The content of carbon, manganese, silicon and other major elements in spring steel is narrow, and the chemical composition must be strictly controlled during smelting. When the silicon content is high, it is easy to form bubbles and other defects. After the ingot is rolled and rolled, the cooling is not easy. Therefore, the raw materials used for smelting must be dry, as much as possible to remove gas and inclusions, and to avoid overheating of the steel.

- Q: In short, in vibration and wave, it is not easy to make mistakes when we grasp the difference and relationship between "displacement" and "displacement relative to the balance position"

- In short, in vibration and wave, it is not easy to make mistakes when we grasp the difference and relationship between "displacement" and "displacement relative to the balance position"

1. Manufacturer Overview

| Location | Suzhou, China |

| Year Established | 2001 |

| Annual Output Value | more than US$ 5 Million |

| Main Markets | North America, South America, Eastern Europe, Southeast Asia, Africa, Mid East, Eastern Asia, Western Europe |

| Company Certifications | ISO/TS 16949; ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | About 170 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | About 35,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Mould Spring with free design

- Loading Port:

- Ning Bo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000Pieces pc

- Supply Capability:

- 100000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords