Hvac Coating Aluminum Coils - Aluminium Coil Sheet for Building Use in Different Alloys

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

Every Owens Corning roof shingle features:

A Fiberglass mat for weather protection and longer life

Colorful mineral granules that reflect the sun's rays and add beauty to the roof

Weathering-grade asphalt that holds the granules on the shingle and waterproofs the roof

The highest fire protection rating for residential applications

Wind resistance for gusts up to 110 mph

Limited product warranties ranging from 20 to 50 years

3. Feature of Aluminum

In 1954, there were 75 registered aluminum alloys. Today, there are more than 530 registered active compositions and that number continues to grow. That underscores how versatile and ubiquitous aluminum has become in our modern world. So what are aluminum alloys and why are they important?

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

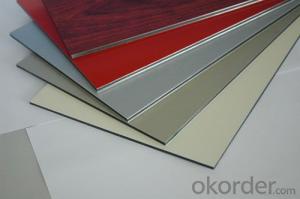

5. Image of Aluminum

6. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: What’s the difference between aluminum tile, coil and sheet? Why?

- Wood pallet is often used, which is easy to transport and can ensure the safety of products.

- Q: How are aluminum coils used in heating, ventilation, and air conditioning (HVAC) systems?

- Aluminum coils hold a vital role in HVAC systems, specifically in heating, ventilation, and air conditioning. These coils are implemented in both the condenser and evaporator parts of the system. In the condenser, the aluminum coils aid in the transfer of heat from the refrigerant to the surrounding air. The refrigerant, which is in a state of high pressure and temperature after compression, flows through the condenser coils. As the air from the surroundings passes over these coils, the heat from the refrigerant moves to the air. This procedure contributes to the cooling of the refrigerant, transforming it from a gas into a liquid state. The cooled liquid refrigerant then moves to the evaporator coil. In the evaporator, the aluminum coils help in the absorption of heat from the indoor air. The liquid refrigerant enters the evaporator coils, where it experiences a change in phase from liquid to gas. As the warm indoor air passes over the coils, the refrigerant absorbs the heat, resulting in the cooling of the air. This cooled air is subsequently circulated back into the room, creating a comfortable indoor environment. The preference for aluminum coils in HVAC systems stems from their outstanding thermal conductivity, resistance to corrosion, and lightweight properties. These characteristics ensure effective heat transfer and enhance the overall performance of the system. Moreover, aluminum coils are more cost-efficient and environmentally friendly compared to materials like copper. Regular maintenance and cleaning of the aluminum coils are imperative to maintain their optimal functioning. Over time, dirt, dust, and debris can accumulate on the surface of the coils, hindering heat transfer and reducing efficiency. Thus, periodic cleaning is essential to preserve the performance of the HVAC system and prolong the lifespan of the aluminum coils.

- Q: wikipedia says welding aluminum by means of stick welding is possible but i have always been told TIG is the only way to weld aluminum. what do i need in order to stick weld aluminum? BTW i have a Lincoln Electric AC 225 Stick Welder

- Stick Welding Aluminum

- Q: What are the different surface textures available for aluminum coils?

- There are several different surface textures available for aluminum coils, each with its own unique characteristics and applications. 1. Smooth: Smooth surface texture is the most basic and common type of finish for aluminum coils. It has a sleek and polished appearance, making it suitable for a wide range of applications such as architectural cladding, signage, and consumer electronics. 2. Stucco: Stucco texture features a raised pattern resembling small pebbles. This texture is achieved by embossing the surface of the aluminum coil, providing enhanced durability and resistance to scratches and dents. It is often used in applications where a more robust and decorative finish is desired, such as roofing, wall panels, and decorative trim. 3. Diamond: Diamond texture features a diamond-shaped pattern embossed onto the surface of the aluminum coil. This texture not only enhances the aesthetic appeal but also provides additional traction and slip resistance, making it ideal for applications such as flooring, stairs, and ramps. 4. Brushed: Brushed texture is achieved by mechanically brushing the surface of the aluminum coil, creating a linear pattern. This finish gives the aluminum a distinctive, satin-like appearance, making it popular for architectural applications such as interior wall cladding, furniture, and decorative elements. 5. Hammered: Hammered texture is achieved by hammering the surface of the aluminum coil, resulting in a unique and irregular pattern. This texture provides a rustic, handcrafted look, making it suitable for applications such as decorative accents, light fixtures, and furniture. 6. Perforated: Perforated texture involves creating a pattern of small holes or perforations on the surface of the aluminum coil. This texture allows for increased airflow, light transmission, and sound absorption, making it commonly used in applications such as ventilation systems, acoustic panels, and decorative screens. These are just a few examples of the various surface textures available for aluminum coils. The choice of texture depends on the specific requirements of the application, including aesthetics, functionality, and durability.

- Q: How are aluminum coils different from other types of metal coils?

- Aluminum coils are different from other types of metal coils primarily due to their unique properties and characteristics. Unlike other metals, aluminum is lightweight, corrosion-resistant, and highly malleable, making it an ideal material for various applications such as construction, automotive, and electronics. Additionally, aluminum coils have excellent conductivity, enabling efficient heat transfer and electrical conductivity. These qualities, coupled with its affordability and recyclability, set aluminum coils apart from other metal coils in terms of versatility and practicality.

- Q: What are the different types of surface treatments for aluminum coils?

- There are various types of surface treatments available for aluminum coils, including anodizing, painting, laminating, and chemical conversion coating.

- Q: What are the different protective film options for aluminum coils?

- Aluminum coils have a range of protective film options available, each with its own benefits and suitability for different applications. Some commonly used options include: 1. PVC Film: These films are highly resistant to moisture, chemicals, and abrasion, making them a popular choice for protecting aluminum coils. They offer excellent surface protection and come in various thicknesses and adhesive strengths. 2. PE Film: Another popular choice, PE films provide good resistance to moisture and UV radiation. They are generally more cost-effective than PVC films and are available in different grades, such as LDPE and LLDPE. 3. PP Film: Known for their tear resistance and high tensile strength, PP films are ideal for applications where coils may undergo rough handling or transportation. They offer good protection against mechanical damage. 4. PET Film: PET films offer exceptional clarity and transparency, making them perfect for applications that require visual inspection of the coils. They also provide good resistance to heat, chemicals, and abrasion. 5. Adhesive Coatings: In addition to films, adhesive coatings can be used to protect aluminum coils. These coatings are directly applied to the coil's surface and create a protective layer against moisture, corrosion, and scratching. When choosing a protective film for aluminum coils, it is crucial to consider factors such as the intended application, environmental conditions, handling processes, and desired level of protection. Seeking guidance from a supplier or manufacturer can help determine the most suitable option for specific requirements.

- Q: Are aluminum coils suitable for decorative purposes?

- <p>Yes, aluminum coils can be used for decoration. They are lightweight, durable, and corrosion-resistant, making them ideal for various decorative applications. Aluminum coils can be shaped and colored to suit different design needs, often used in architectural features, interior design elements, and even in art installations. Their versatility and aesthetic appeal make them a popular choice for both commercial and residential decoration.</p>

- Q: What is the typical conductivity of aluminum coils?

- The typical conductivity of aluminum coils is relatively high, with values ranging from 34 to 38 million Siemens per meter (MS/m) at room temperature. Aluminum is known for its excellent electrical conductivity, which is why it is widely used in various electrical applications, including power transmission lines, electrical conductors, and coils. This high conductivity allows for efficient and effective flow of electric current through aluminum coils, making them suitable for conducting electricity in a reliable and efficient manner.

- Q: Explain the distinctions between aluminum coil and aluminum foil, highlighting their physical properties and applications.

- <p>Aluminum coil and aluminum foil are both made from aluminum but differ in thickness and applications. Aluminum coil is a flexible and continuous roll of aluminum, typically thicker and stronger than foil, used in manufacturing processes such as construction, packaging, and automotive parts. It can be easily cut and shaped. Aluminum foil, on the other hand, is a very thin and lightweight material, often used for food packaging, cooking, and insulation due to its excellent barrier properties against air, moisture, and light. It's less durable than coil and is not typically used in structural applications.</p>

Send your message to us

Hvac Coating Aluminum Coils - Aluminium Coil Sheet for Building Use in Different Alloys

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords