HPA Geocells for Slope Stabilization with CE Certificate for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 85800 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

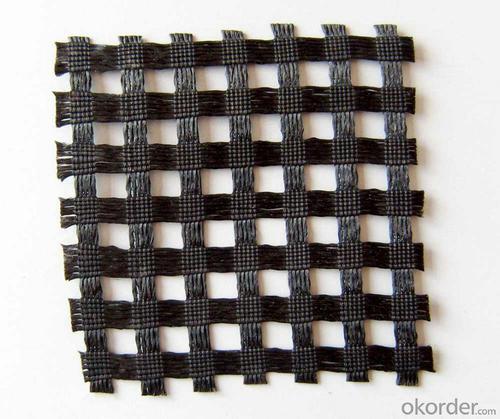

The Description of Geogrid for slope stabilization

Geogrid for slope stabilization is a kind of new favorable earthwork base material to strengthen the road surface and roadbed. This product is made by weaving and covering fiberglass filament. It is featured by high vertical and horizontal tensile strength, low unit extension, high flexibility, and favorable high and low temperature resistance. The products after surface covering own the favorable property of alkali resistance and aging resistance.

The details of Geogrid for slope stabilization

| Type: | Geogrid | Material: | geogrid for slope stabilization | Place of Origin: | China (Mainland) |

| Certificates: | CE,ISO | Color : | White & Black | Width : | 1m--6m |

| Length | 50-200m | Mesh Size: | 10-40mm | Tensile Strength | 30KN-300KN |

| Area Weight | 130-900g/sm | Package | PP bags or PE film | Approximate mesh size | 12.7*12.7 25*25 40*40 |

Packaging & Delivery

| Packaging Details | PP bags or PE film. Or Packed as customers' requests; |

| Delivery Detail | 10-20days after see the payment. |

Remarks: we are very large fortune 500 enterprise with more than 20branches in worldwide, and have almost ten years export experience in geosynthetic field. We have kunlun bank account and have many Iran geosynthetics customers.So if any question or support, please just feel free to contact me at any time.

- Q: How do geogrids improve the performance of retaining walls in earthquake-prone areas?

- Geogrids enhance the performance of retaining walls in earthquake-prone areas by providing additional reinforcement and stability. They work by interlocking with the soil or fill material, increasing its strength and preventing lateral movement. This reinforcement helps to distribute the forces generated during an earthquake, reducing the risk of wall failure and enhancing overall structural integrity.

- Q: How do geogrids enhance the performance of mechanically stabilized earth walls?

- Geogrids enhance the performance of mechanically stabilized earth walls by providing tensile strength and reinforcing the soil structure. They distribute lateral forces and soil loads more evenly, reducing the potential for wall failure or deformation. Additionally, geogrids improve the overall stability and durability of the wall by increasing its resistance to settlement, slope erosion, and seismic activity.

- Q: What are the long-term maintenance requirements for geogrids?

- The long-term maintenance requirements for geogrids are typically minimal. Once installed properly, geogrids generally do not require any specific maintenance. However, regular inspections are recommended to ensure that the geogrids are functioning as intended and to identify any potential damage or deterioration. In case any issues are detected, prompt repairs or replacements should be carried out to maintain the effectiveness of the geogrids over time.

- Q: What is the effect of cyclic loading on geogrid behavior?

- The effect of cyclic loading on geogrid behavior can lead to degradation and decreased performance over time. Continuous repetitive loading can cause the geogrid to undergo stress and strain cycles, which can result in material fatigue, reduced stiffness, and a decrease in its ability to provide reinforcement or confinement. This can lead to increased deformation, reduced load-bearing capacity, and potential failure of the geogrid. Therefore, it is crucial to consider the potential effects of cyclic loading when designing and using geogrids in engineering applications.

- Q: What are the standards for geogrid testing and certification?

- The standards for geogrid testing and certification are outlined by various organizations such as ASTM International (American Society for Testing and Materials) and ISO (International Organization for Standardization). These standards cover a range of parameters including tensile strength, elongation, aperture size, junction strength, and durability. Testing methods and acceptance criteria are defined to ensure that geogrids meet the necessary performance requirements for their intended applications. Certification is typically granted by accredited third-party laboratories or certification bodies after successful compliance with these standards.

- Q: What is the effect of strain rate on geogrid behavior?

- The effect of strain rate on geogrid behavior is that it influences the mechanical properties and performance of the geogrid material. Higher strain rates typically result in increased stiffness and strength, as well as reduced deformation and creep behavior. This is due to the time-dependent nature of geogrids, where faster loading rates induce a more immediate response from the material. Therefore, understanding and accounting for strain rate effects is crucial in designing and predicting the behavior of geogrids in various engineering applications.

- Q: Are geogrids suitable for use in slope reinforcement during excavation?

- Yes, geogrids are suitable for use in slope reinforcement during excavation. Geogrids are commonly used in slope stabilization and reinforcement projects due to their high tensile strength and ability to distribute loads. They can effectively prevent soil erosion and provide stability to slopes during excavation, making them a reliable choice for such applications.

- Q: What are the specifications of the road geogrid

- Warp knitted grating, steel plastic grille, plastic grille, fiberglass grille...... There are many kinds of specifications for each grid

- Q: Can geogrids be used in ground stabilization for water treatment plants?

- Yes, geogrids can be used in ground stabilization for water treatment plants. Geogrids are commonly used in civil engineering projects to improve the stability and load-bearing capacity of soil. In the case of water treatment plants, geogrids can help prevent soil erosion, reinforce embankments, and provide stability to the ground, ensuring the safe and long-lasting operation of the facility.

- Q: Can geogrids be used in retaining wall reinforcement systems?

- Yes, geogrids can be used in retaining wall reinforcement systems. Geogrids are commonly used to enhance the stability and strength of retaining walls by improving soil retention and reducing lateral pressure. They provide additional support to the wall structure and prevent soil erosion, helping to increase the overall durability and longevity of the retaining wall.

Send your message to us

HPA Geocells for Slope Stabilization with CE Certificate for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 85800 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords