700mm HP Grade Graphite Electrode for EAF Foundry Use

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Graphite Electrode Description

Topfly Material has complete production lines, which include raw material mixing, forming line, baking line, impregnation equipment, graphitization line and machining and shaping line.

Graphite electrodes, widely used in steelmaking, non ferrous, silicon industry. According to their level of quality, it can be divided into RP, HP and UHP grade. This item is for UHP grade graphite electrode. Resistivity: ≤6.5ohm, Bulk Density: ≥1.65g/cm3. Diameter is 300-600mm, length is 1800±100mm.

2.Main Features of the Graphite Electrode

(1) High quality and carbon content, widely used in the foundry market

(2) Competitive price, we have price advantage for UHP.

(3) High density ≥1.65g/cm3 and low resistivity≤6.5ohm

(4) Large quantity in stock, you can order directly.

3.Graphite Electrode Images

More products for your reference:

Packaging: Wooden Pallets

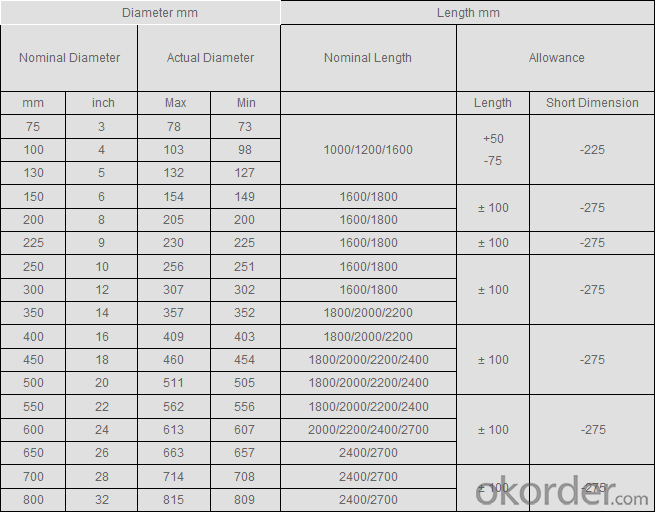

4.Graphite Electrode Specification

5.FAQ

We have organized several common questions for our clients, may help you sincerely:

(1) How to guarantee the quality of the products?

We have established the international advanced quality management system, every link from raw material to final product we have strict quality test; we resolutely put an end to unqualified products material flowing into the market. At the same time, we will provide necessary follow-up service assurance.

(2) MOQ

For trial order, we accept 20 MT.

(3) Payment term

30% deposit, balance against the BL copy; 100% L/C at sight.

(4) How long can we receive the product after purchase?

We have large quantity in stock, and we could machine it to the size you need, so the delivery time is around 25 days after receiving your deposit or L/C.

- Q: Is graphite electrode good for foreign trade?

- I do graphite electrode production, but also do trade. The profit depends on the price you talked about. It should be around 2000.

- Q: Why is graphite conductive electrode oxidized?

- Coal tar pitch is a kind of high temperature resistant graphite conductive material, which is made of coal tar pitch as binder. It is made by calcination, crushing, mixing, kneading, forming, roasting, graphitization and mechanical processing. It is called graphite electrode

- Q: Why use platinum ferroalloy instead of iron as electrode?

- Its surface properties must comply with the characteristics of the additives so that they can be dispersed evenly.

- Q: Graphite electrode specifications, graphite electrode manufacturers which good?

- Graphite electrode has good electrical and chemical stability. It has high mechanical strength, low impurity content and good vibration resistance at high temperature. It is a good conductor of heat and electricity. Qingdao Chenyang graphite graphite electrode quality is good, they are a direct manufacturer of graphite electrode. Hope to be of some help to you.

- Q: The original battery is not necessary to form the electrode potential? Why can we use graphite as electrode only? No potential difference.

- External electronic wire and the directional movement of ions in the solution of the directional movement between the poles of a closed loop, so that the two electrode reaction, electron transfer process, ordered a current converting chemical energy to electrical energy.Attention, here, "the ion does not go ashore, the electron does not enter the water"." That is the external circuit of graphite electrode is composed of electron flow and electrolyte ion flow; graphite electrode is to produce voltage and electrolyte, and to provide or absorb electrons

- Q: What's the purpose of the electrode material?When the electrolytic molten state of NaCl is said, what is the use of the graphite electrode and the iron electrode?

- The copper electrode used for finishing size of the copper electrode discharge speed is not fast but spent graphite electrode is relatively smallRequirements of the high surface, the appearance of products are copper electrode discharge processingThe iron electrode is not clear enough to be used

- Q: After vacuum melting of quartz crucible, there are three graphite electrode rods. What's the adjustment?

- The shorter one is the farther away from the other, and the shorter one is the shorter one

- Q: Electrolysis of CuCl2 solutions with graphite electrodes

- CuCl2 refers to a copper chloride ionization ionization ion and chloride ion in aqueous solution, the equivalent of CuCl2 does not exist, but there are only Cu2+ and Cl-, even if there is no electricity, the ionization will happen, because this is the nature of it.

- Q: I remember the more lively metal, the electron?

- C metal is copper, because a dilute sulfuric acid into the H2 precipitation, then definitely not copper. And the inactive first precipitate

- Q: How do graphitized electrodes differentiate between high power and low power?

- In an electrolytic cell, the current from a class called graphite anode plate into the electrolyte electrolysis industry, the anode is made of plate shape, so called graphite anode plate, widely used in electroplating, wastewater treatment, industrial anti-corrosion equipment or special materials.

Send your message to us

700mm HP Grade Graphite Electrode for EAF Foundry Use

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords