400mm Graphite Electrode for RP Grade for Foundry Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Graphite Electrode Description

We has complete production lines, which include raw material mixing, forming line, baking line, impregnation equipment, graphitization line and machining and shaping line. Our annual capacity is 60,0000tons.

2.Main Features of the Graphite Electrode

(1) Direct manufacturer, office based on Beijing.

(2) Competitive price with prior quality

(3) High density with low resistivity

(4) High carbon content

(5) RP HD HP UHP Grade for your reference

3.Graphite Electrode Images

Packaging: Wooden Pallets, well packaged.

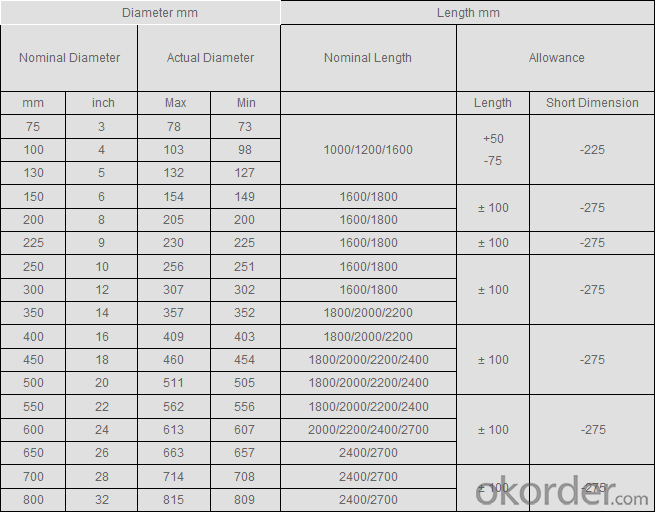

4.Graphite Electrode Specification

5.FAQ

(1) How to guarantee the quality of the products?

We have established the international advanced quality management system, every link from raw material to final product we have strict quality test; we resolutely put an end to unqualified products material flowing into the market. At the same time, we will provide necessary follow-up service assurance. We welcome you to visit our mill.

(2) MOQ

For trial order, we accept 20 MT.

(3) Payment term

30% deposit, balance against the BL copy; 100% L/C at sight.

(4) How long can we receive the product after purchase?

We have large quantity in stock, and we could machine it to the size you need, so the delivery time is around 25 days after receiving your deposit or L/C.

- Q: Thermal expansion coefficient of graphite

- Thermal expansion coefficient (100 degrees Celsius --600 degrees Celsius) diameter 200--500 graphite electrode body is not greater than 2.410 of the negative four times per degree Celsius

- Q: Why graphite can be used as conductive material?

- Graphite used in the electrical industry requires a high degree of particle size and grade. Such as alkaline batteries and some special electric carbon products, requiring graphite particle size control within the scope of the project, grade above, harmful impurities are required in the following. The graphite used in a picture tube for television is required below. As a wear-resistant and lubricating material, graphite is often used as a lubricant in the mechanical industry.

- Q: What is the graphite furnace electrode with a diameter of 400?

- With the development of EAF steelmaking technology, the steel-making technology is developing towards large scale and ultra high power. The graphite electrode is mainly made of large size graphite electrode and ultra high power graphite electrode.

- Q: Graphite electrode specifications, graphite electrode manufacturers which good?

- The key is you use and what type of need, say, abroad, what Dongyang, sigley are good, but also, very expensive, you can also choose to try our home

- Q: Will the brush grease not short-circuit the commutator?

- Graphite, on the other hand, has good lubrication. The graphite base electrode will form a layer of carbon film when it rotates on the surface of the motor commutator. It can reduce the friction coefficient between the brush and the commutator and reduce the wear of the commutator effectively.

- Q: Are graphite and carbon electrodes the same? What kinds of ore furnaces are used?

- The main components of carbon electrodes are graphite, carbon powder and other impurities which are not converted into graphite. The resistivity is higher than that of graphite electrode. These electrodes are mostly used in electric furnace steelmaking, smelting aluminium oxide and other electric arc furnaces.

- Q: Why is the production of one ton of ultra high power graphite electrode requires 1.05 tons of coke?

- Petroleum coke is divided into needle coke and sponge coke and projectile reef, fixed carbon content components of petroleum coke is around 80%

- Q: Can Naiduo high temperature graphite

- The reinforced graphite gasket is made of flexible graphite tape or flexible graphite and is molded into ring products of different sizes. Suitable for hot water, high temperature, high pressure steam, heat exchange liquid, nitrogen gas, organic solvent, hydrocarbon, low temperature liquid and other medium. Used in compressors, machines, pumps, valves, chemical instruments, instruments, etc..

- Q: Graphite electrode press device

- Ultra high power graphite electrodes. Use of graphite electrodes with a current density greater than 25A / cm 2. Used primarily in ultra high power arc furnaces

- Q: Why is graphite a negative pole and copper is an anode?

- Electrolysis (Electrolysis) is the current through the electrolyte solution or molten electrolyte (also called electrolyte), caused by the redox reaction in the cathode and the anode, the electrochemical cell can occur when an external DC voltage in the electrolysis process.

Send your message to us

400mm Graphite Electrode for RP Grade for Foundry Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches