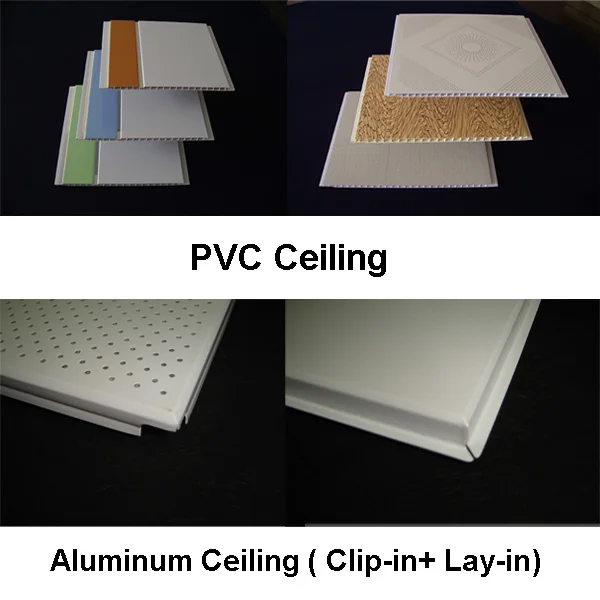

Interlocking PVC Ceiling Panels - Hot Stamping 20cm Middle Groove PVC Panels for Interior Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot stamping 20cm middle groove pvc panels for interior decoration

Specification:

1.Width: 0.915,1,1.22,1.56,2.05m

2.Thickness: 1~40mm

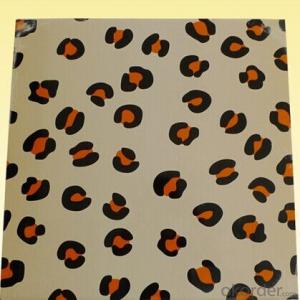

3.Colors: as your requirementThickness: 1mm~25mm

Good features:

1. Light weight,good tenacity, high rigidity

2. Fireproof and flame retardant

3. Good insulation

4. No sopping, no deformation

5. Easily to processed

6. Good plasticity, being an excellent thermoform material

7. Sub-light surface and elegant vision

8. Anti-chemical corrosion

9. Suitable to silk screen printing

10. With imported dyes, unfading and anti-aging

Applications:

Advertising: signs, exhibition stands, routing sheets, etc..

Industry: Manufacturing industries, control cabinets, etc., and warning signs.

Construction: Wall cladding, sandwich panels, interior decoration etc.

pvc ceiling tiles pvc panels for sale

PVC Sheet-applied treatments:

Materials processing: Cut; Drilling; Milling; nail etc.

Heat application: wisting, bending; Resource work; Heat styling

Other: Digital Printing; Application of alternative soil; Application sheets; Painting

Produce Arrange:

PVC foam sheet | |||||

Specifications | Thickness(mm) | Densityg/cm3) | MOQ(pc) | Color | Application |

0.915*1.83 | 1--10 | 0.5-0.8 | 1000 | White | Sign board |

1.22*2.44 | 1--10 | 0.5-0.8 | 500 | White/Colored | |

1.56*3.05 | 1--10 | 0.5-0.8 | 500 | White/Colored | |

2.05*3.05 | 1--10 | 0.6-0.9 | 500 | White/Colored | |

PVC Celuca Sheet | |||||

Specifications | Thicknessmm | Densityg/cm3) | MOQ(pc) | Color | Application |

1.22*2.44 | 4--40 | 0.5-0.8 | 500 | White | Furniture |

1.56*3.05 | 8--40 | 0.6-0.8 | 500 | White | Furniture |

PVC rigid sheet | |||||

1.22*2.44 | 1--3 | 1.42 | 500 | Sign board |

Our main products in CNBM:

pvc ceiling tiles pvc panels for sale

- Q: PVC board how rub rub

- PVC style, rich colors. Giving a stylish, crisp feeling. Suitable for young married couples to use.

- Q: Pvc board and fire board glue what glue?

- What is the fire board material? What is the requirement of bonding? The general situation is to use Wan Nengjiao can, fixed time slightly longer, placed 24 hours. After the glue to the bubble (key point). If you know your request, you can specifically recommend your glue!

- Q: What are the disadvantages of PVC glue?

- PVC floor defects: ???????? 1, the construction of high demand ???????? 2, afraid of cigarette butts ???????? 3, non-natural materials ???????? Homogeneous heart PVC flooring defects: ???????? 1, the construction of high demand ???????? 2, poor stain resistance, must always wax maintenance ???????? 3, poor wear resistance ???????? 4, poor dimensional stability ???????? 5, afraid of cigarette butts ???????? 6, a single color, not enough diversity ???????? 7, poor impact resistance

- Q: Sun room,studded partition over the windows, pvc on the exterior. Losing heat? What can I do? Tiled roof?

- adequate insulation should be installed. the build is best made of blockwork, double glazed u-pvc windows, with damp proof courses(D.P.C), insulation in roof space or between rafters and D.P.C under roof tiles.

- Q: How to paste the pvc board to the wall

- How thick is it? First glue glue, and then nail fixation.

- Q: Or what material can replace pvc requires toughness Transparency High flat thickness around 6mm

- Transparent high can replace a lot of PVC, such as TPR, TPU, or SBS, SEBS, etc. Toughness and transparency only more than PVC, not less than PVC

- Q: Home wall decoration PVC wall panels how practical it

- Home wall decoration, PVC wall panels are not practical, is not recommended to use. PVC is actually a vinyl polymer, the material is a non-crystalline material. PVC materials in the actual use of often added stabilizers, lubricants, auxiliary processing agents, colorants, impact agents and other additives. With non-flammability, high strength, weather resistance and excellent geometric stability. PVC has a strong resistance to oxidants, reducing agents and strong acids. However, it can be strongly oxidized acid such as concentrated sulfuric acid, concentrated nitric acid corrosion and does not apply with aromatic hydrocarbons, chlorinated hydrocarbons in contact with the occasion.

- Q: PVC floor construction technology content is high

- Pvc floor construction requirements are very high, the ground requires a higher! Pvc floor laying membrane for PVC glue, staircase selection of universal glue, Pvc floor, pvc floor, pvc floor, pvc floor, pvc floor, pvc floor, pvc floor, pvc floor, pvc floor, pvc floor, pvc floor, pvc floor Pvc floor, pvc floor size, pvc floor specifications, pvc floor, how much money a flat, Nanjing pvc floor, Hefei pvc floor Hello landlord! Choose pvc floor must choose the site dedicated, the wrong choice and the use of material life, you know! Pvc floor types are many, mainly divided into coil and sheet, the most common is the coil, pvc floor series of thousands of series, as the current wide: commercial flooring (PVC flooring such as: shopping malls, hotels, Hospitals, schools, kindergartens, homes, offices, airports), sports floor (stadiums, badminton venues, table tennis grounds, basketball courts, gyms, kindergartens), dance floor (dance room, dance room, dance hall, dance rehearsal hall, Dance class, stage, ballet, Latin dance, dance practice room, dance body room, dance training room)

- Q: In the home improvement of the kitchen with the best material, is the aluminum plate is good, or PVC board or aluminum plate is good

- Aluminum-plastic plate with aluminum plate, because the aluminum plate has a size specifications, a single use and can not be sure to meet the site construction

- Q: What is the density of the PVC board?

- Measure the most accurate! Is the load divided by the volume?

Send your message to us

Interlocking PVC Ceiling Panels - Hot Stamping 20cm Middle Groove PVC Panels for Interior Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords