Hot Sale Cold Rolled Steel DC01 CRC Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Info.

Model NO.:DC01

Surface Treatment:Oiled

Certification:ISO

Technique:Cold Rolled

Standard:ASTM, JIS, GB, DIN, BS

Application:Base Metal

Edge:Ec & Em

Stock:Stock

Steel Grade:DC01

Product Description:CRC Coil

Brand Name:Cheeho & OEM

Heat Treatment:Annealed

Temper Type:Ba

Margin Status:Ec & Em

Surface Condition:Sc & SD

Surface Quality:FC & Fd

Inner Diameter:508-610mm

Approved Certificate:SGS & ISO & BV & TUV

Export Markets:Global

Additional Info.

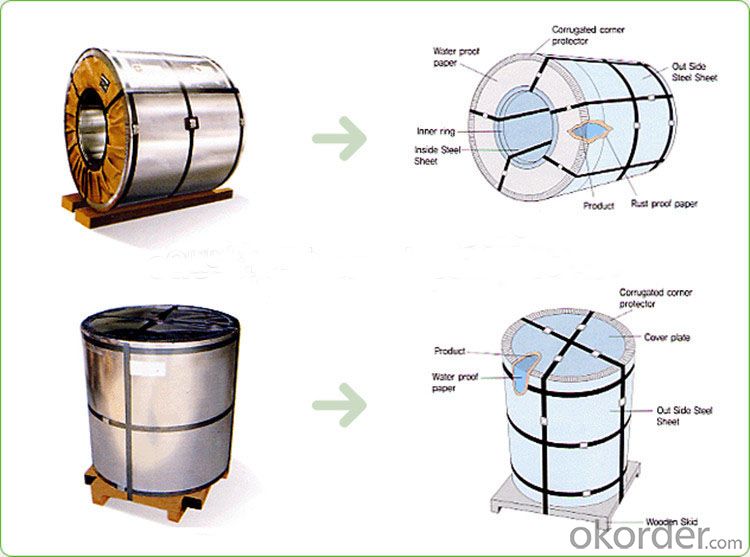

Packing:Standard Seaworthy Package

Standard:SGS & ISO & BV & TUV Approved

Origin: China

HS Code:72091790

Production Capacity:250000mt/Year

Product Description

Brief Introduction

The CRC Coil is steel that has been worked below its recrystallization temperature by passing it between a pair of rollers. Recrystallization temperature is the temperature at which grains in the lattice structure of the metal have been rearranged, leaving it free of strain and deformations. The CRC Coil is pre-treated before being cold rolled with a process known as pickling, which uses strong acids to remove scale and other impurities. The CRC Coil is then passed through rollers to reduce its thickness. Most cold rolling takes place in multiple passes and as the size of the CRC Coil is further reduced, its strength and hardness both increase, but its ductility decreases. After cold rolling, heating the metal up in a process known as annealing can restore some of its ductility. The final CRC Coil may be manufactured in the form of sheets, strips, bars, or other forms.

Specification

1. Thickness: 0.4-2.0mm

2. Width: 900-1250mm

3. Inner Diameter: 508mm

4. Weight of Steel Coil: 3-15MT

5. Heat Treatment: Annealed

6. Margin Status: EC & EM

7. Surface Quality: FB&FC

8. Surface Status: SB & SD

9. Surface Treatment: Oiling

Mechanical Properties

1. Yield Strength: ≤ 320MPa

2. Tensile Strength: ≤ 370MPa

3. Elongation (L=50mm, b=25mm) When:

(1) Nominal Thickness <0.25mm: 30%

(2) Nominal Thickness 0.25mm-<0.40: 32%

(3) Nominal Thickness 0.40-<0.60mm: 34%

(4) Nominal Thickness 0.60-<1.0mm: 36%

(5) Nominal Thickness 1.0-<1.6mm: 37%

(6) Nominal Thickness >1.6mm: 38%

Packing

We use Seaworthy Package to make sure CRC Coil is well-protected during the long ocean voyage.

Application

1. Base metal for coated and dipped products.

2. Home appliance

3. Precise welding tube

4. Flux cored welding wire

5. Bicycle, battery shell,

6. Automobile fitting, hardware

7. Enameling industry etc.

Superiority

1. High precision of dimensional tolerance

2. Excellent mechanical property such as the yield strength and tensile strength, etc.

3. Being highly resistant to denting

4. Exhibits useful magnetic properties

5. High quality surface finish and get well prepared for the surface coating

6. Available in a variety of sizes and shapes with characteristics useful in a wide range of applications

Chemical Components

| Grade | Chemical Components | ||||

| C | Mn | P | S | Alt | |

| DC01 | ≤0.12 | ≤0.50 | ≤0.035 | ≤0.025 | ≥0.020 |

| DC03 | ≤0.10 | ≤0.45 | ≤0.030 | ≤0.025 | ≥0.020 |

| DC04 | ≤0.08 | ≤0.40 | ≤0.025 | ≤0.020 | ≥0.020 |

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

4.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day

- Q: Nickel is ferro magnetic in nature. But when it is added with stainless steel, it makes stainless steel non-magnetic. What is the structural changes happened with the presence of nickel?

- Dear Ian, Magnetism doesn't add up or average out in that manner. Ferro-magnetism requires that all the spins align. This is a complex effect and needs a subtle interaction between adjacent atoms in the lattice and their singlet electrons. The distance between the the atoms is what is important. Some stainless steels are ferromagnetic because they have the correct spacing, others are not because the spacing is wrong. This spacing is influenced by the makeup of the alloy. Hope that helps a bit:RufusCat Copyleft:RufusCat

- Q: I want to start getting throwing knives and i was wondering what material is best for quality, but still cheap. I also saw some 440 stainless steel knives that i liked and wanted to know if the material was good

- For throwing knives, 440 isn’t necessarily a bad choice. Does it list whether it is 440c or 440b? That matters somewhat. The advantages of 440 Stainless is that it’s relatively hard (for a stainless), it resists rust significantly, and it’s not so hard that it would shatter or break. On the down side 440 is notorious for not taking or holding an edge, but for a throwing knife, that’s probably not much of an issue. If you’re looking for something to train with, you’re fine here. It’s plenty of steel enough to stick in wood or other targets. Odds are it won't bend if you slam it into some wood. If it lands on concrete, eh, it's going to scratch and all that jazz, and it might hurt the tip if it hits first, but as has been said, you can use a file or grinder to get the tip back.

- Q: What are the dimensions of steel coils used in the storage tank industry?

- Steel coils used in the storage tank industry come in various dimensions, depending on the specific requirements of the tank being manufactured. Generally, these coils are available in different sizes and thicknesses. The width of the steel coils can range from approximately 600 millimeters to 2,400 millimeters. Similarly, the length can vary from a few meters to tens of meters. The thickness of the coils can also differ, typically ranging from 1.5 millimeters to 10 millimeters or more. Factors such as the size and capacity of the storage tank, the material being stored, and the structural requirements of the tank determine these dimensions. Consequently, the tank manufacturer or designer would determine the specific dimensions for a given storage tank project, following industry standards and project specifications.

- Q: If rail ties were melted, would they be like any other type of steel?

- If you were to melt rail steel down and pour it into ingots, I doubt anyone would check to find it's source although a skilled metalurgist would know. While the steel was melted you could toss a handful of old horseshoes in and change the composition and no one would know. Good luck with your project, I would like to know how it turns out.

- Q: How are steel coils used in the production of prefabricated buildings?

- Steel coils are used in the production of prefabricated buildings as they serve as a primary material for manufacturing structural components such as beams, columns, and frames. These coils are unrolled and shaped into various sections, which are then welded or bolted together to form the skeleton of the building. Their strength, durability, and malleability make steel coils an ideal choice for constructing robust and reliable prefabricated structures.

- Q: What is the average size of a steel coil?

- The average size of a steel coil can vary depending on the specific industry and application. However, typical sizes range from 0.15mm to 3.5mm in thickness and 600mm to 2,000mm in width. The coil diameter can also vary, usually ranging from 600mm to 2,000mm.

- Q: What are the common packaging defects in steel coils?

- Some common packaging defects in steel coils include improper wrapping, inadequate strapping or banding, loose or damaged packaging materials, moisture or water damage, and insufficient protection against impacts or abrasion.

- Q: What is the maximum diameter of a steel coil?

- The maximum diameter of a steel coil can vary depending on multiple factors such as the type of steel, coil weight, and the specific dimensions required by the manufacturer. However, in general, steel coils can range in maximum diameter from a few feet to several meters.

- Q: I read that contrary to popular belief, today's folded steel swords are only made that way for tradition and cosmetics. In the past steel was very impure and therefore had to be folded in order to make a good sword. Today's steel manufacturing provides very pure steel and so folding the metal only makes it look nicer, but does nothing to improve the function of the blade.What do you think of this?

- Folding Sword

- Q: How are steel coils used in the production of automotive chassis?

- Steel coils are used in the production of automotive chassis as they provide the primary material for constructing the framework of the vehicle. These coils are first processed and shaped into the desired form, such as beams or plates, which are then welded together to form the chassis. The high strength and durability of steel make it an ideal choice for withstanding the stresses and loads experienced by the chassis, ensuring the safety and structural integrity of the vehicle.

Send your message to us

Hot Sale Cold Rolled Steel DC01 CRC Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords