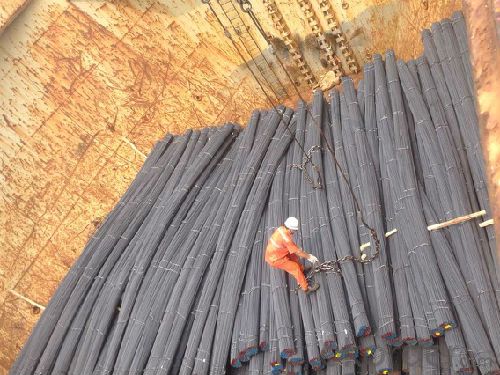

Hot Rolled Steel Rebars Deformed bar ASTM

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled Steel Rebars Deformed bar ASTM at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Steel Rebars Deformed bar ASTM are ideal for structural applications and are widely used in forest region, Mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line..

Product Advantages:

OKorder's Hot Rolled Steel Rebars Deformed bar ASTM are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: HRB335,HRB400,HRB500

Certificates: ISO, SGS, BV, CIQ

Diameter:10mm-32mm

Packing: products are packed in coils and shipped by break bulk or containers

FAQ:

Q1: How many tons of steel products could be loaded in containers?

A1: Usually the steel products are delivered by bulk vessel because of the large quantity and the freight. However, there are no bulk vessel enter some seaports so that we have to deliver the cargo by containers. The 6m steel product can be loaded in 20FT container, but the quantity is changed according to the size, usually from 18tons to 25tons.

Q2: what is the difference between actual weight and theoretical weight?

A2: All the section steel has two weights: actual weight and theoretical weight. Actual weight is the weighing out when the product delivered from the mill. Theoretical weight is calculated by pieces. The invoice can be based on each of them as your request.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 45-60days.

Images:

- Q: What are the guidelines for the proper spacing of steel rebars in slabs?

- The guidelines for the proper spacing of steel rebars in slabs are crucial to ensure the structural integrity and strength of the concrete slab. Here are the general guidelines to follow: 1. Rebar Diameter: The diameter of the steel rebar should be determined based on the load and design requirements. Common rebars sizes range from 6mm to 32mm. 2. Spacing: The spacing between rebars is determined by the thickness of the slab and the design specifications. As a general rule, the spacing should not exceed three times the slab thickness. For example, if the slab thickness is 150mm, the maximum spacing between rebars should be 450mm. 3. Edge Distance: The distance between the rebar and the edge of the slab is also crucial. The minimum edge distance should be at least 50mm to prevent cracking and ensure proper load distribution. 4. Clear Cover: The clear cover refers to the distance between the rebar and the surface of the slab. It is essential to provide sufficient clear cover to protect the rebar from corrosion. The clear cover requirements vary depending on the environmental conditions, but commonly range from 20mm to 40mm. 5. Reinforcement Ratio: The reinforcement ratio is the amount of steel reinforcement used per unit area of the slab. This ratio is determined by the load requirements and the design specifications. Typically, the reinforcement ratio ranges from 0.5% to 2%. 6. Lap Splicing: In cases where the length of the rebar is insufficient, lap splicing is required. The lap length should be determined based on the rebar diameter, grade, and design requirements. 7. Placement: The rebars should be placed accurately and securely inside the slab formwork. Proper alignment and placement ensure that the rebars are positioned correctly to resist the anticipated loads. It is important to note that these guidelines are general and may vary depending on the specific project, structural design, and local building codes. It is recommended to consult with a structural engineer or refer to the relevant building codes and standards for precise guidelines specific to your project.

- Q: How do steel rebars perform in extreme weather conditions?

- Steel rebars are highly durable and perform exceptionally well in extreme weather conditions. They can withstand high temperatures, intense cold, and exposure to moisture without compromising their strength and integrity. The robust nature of steel rebars makes them an ideal choice for reinforcing concrete structures in areas prone to hurricanes, earthquakes, and other severe weather events.

- Q: Can steel rebars be used in seismic-resistant structures?

- Yes, steel rebars can be used in seismic-resistant structures. Steel rebars have excellent tensile strength and ductility, making them an ideal reinforcement material for concrete structures in earthquake-prone areas. When properly designed and installed, steel rebars can help increase the structural integrity and resistance of buildings to seismic forces. They provide additional strength and flexibility to the concrete, allowing it to better withstand the lateral and vertical loads exerted during an earthquake. Moreover, steel rebars can effectively dissipate and absorb the energy generated during seismic events, reducing the potential for structural damage or collapse.

- Q: Are there any health and safety concerns related to steel rebars?

- Yes, there are several health and safety concerns related to steel rebars. Firstly, handling and lifting steel rebars can pose risks of musculoskeletal injuries such as strains, sprains, and back injuries. These rebars are heavy and often require manual handling or the use of heavy machinery, which can increase the risk of accidents and injuries. Secondly, steel rebars are often coated with chemicals to prevent corrosion. These coatings can contain hazardous substances such as toxic metals or volatile organic compounds (VOCs). Exposure to these chemicals through inhaling fumes or direct contact with the skin can lead to health issues, including respiratory problems, skin irritation, and chemical burns. Furthermore, steel rebars are commonly used in construction sites, which can be hazardous environments. Workers may face risks of falling rebars, tripping over them, or being struck by them. Additionally, improper installation or positioning of steel rebars can compromise the structural integrity of the construction, potentially leading to accidents or collapses. To mitigate these health and safety concerns, it is important to provide appropriate training and personal protective equipment (PPE) to workers handling steel rebars. Employers should also enforce proper lifting techniques and safe work practices to prevent musculoskeletal injuries. Adequate ventilation systems and the use of respiratory protection can help in reducing exposure to hazardous chemicals. Lastly, regular inspections and adherence to construction regulations can ensure the proper placement and installation of steel rebars, minimizing the risk of accidents and structural failures.

- Q: What is the process of anchoring steel rebars in masonry walls?

- The process of anchoring steel rebars in masonry walls involves several steps. Firstly, the masonry wall is constructed, leaving gaps or voids where the rebars will be inserted. Secondly, the rebars are cut to the desired length and then inserted into the pre-determined positions in the wall. Next, the rebars are securely anchored or tied to the masonry using various methods such as tying them with wire or using specialized anchoring devices. This ensures that the rebars are firmly embedded within the masonry structure, providing reinforcement and strength to the wall. Finally, the rebars are inspected to ensure they are properly anchored and meet the required specifications and standards.

- Q: What is the role of steel rebars in load-bearing structures?

- The role of steel rebars in load-bearing structures is to provide reinforcement and increase the overall strength and durability of the structure. Steel rebars are embedded within concrete to enhance its tensile strength, as concrete alone is weak in tension. By distributing and resisting the applied loads, rebars help prevent cracks and failures, ensuring the stability and longevity of the load-bearing structure.

- Q: How are steel rebars measured and priced?

- Steel rebars are measured and priced based on their weight and length. The weight of a steel rebar is usually measured in pounds or kilograms, while the length is measured in feet or meters. The weight of a rebar is determined by its diameter, which is typically measured in millimeters or inches. To calculate the price of a steel rebar, the weight is multiplied by the cost per unit weight. The cost per unit weight can vary depending on factors such as the type of steel used, the market demand, and the supplier. This price is usually quoted in terms of cost per pound or cost per kilogram. In addition to the weight and length, other factors may also influence the pricing of steel rebars. These can include factors such as the grade of steel, the manufacturing process, and any additional treatments or coatings applied to the rebar. It is important to note that the pricing of steel rebars can vary from supplier to supplier, so it is advisable to obtain multiple quotes and compare them before making a purchasing decision.

- Q: Can steel rebars be used in historical bridge restoration?

- Yes, steel rebars can be used in historical bridge restoration. In many cases, historical bridges may have deteriorated or suffered damage over time, and steel rebars can provide strength and stability during the restoration process. Steel rebars are commonly used in reinforced concrete structures and can help reinforce the bridge's structural integrity. However, it is important to consider the aesthetics of the historical bridge and ensure that the use of steel rebars does not compromise its historical value or appearance. Preservation guidelines and consultations with historical experts can help determine the appropriate use of steel rebars in historical bridge restoration projects.

- Q: What are the different grades of steel rebars used in bridge construction?

- The construction of bridges requires the use of different grades of steel rebars, which are selected based on the specific demands and load-bearing capacities of the structure. The following are the most frequently employed grades of steel rebars in bridge construction: 1. Grade 40: This is the lowest grade of steel rebar utilized in bridge construction. It possesses a minimum yield strength of 40,000 pounds per square inch (psi). Grade 40 steel rebars are typically employed for lighter loads and smaller bridge structures. 2. Grade 60: This is the grade of steel rebar most commonly used in bridge construction. It boasts a minimum yield strength of 60,000 psi. Grade 60 steel rebars are suitable for medium to heavy loads and are frequently employed in bridge piers, girders, and deck slabs. 3. Grade 75: This grade of steel rebar possesses a minimum yield strength of 75,000 psi. Grade 75 steel rebars are employed for heavy loads and large bridge structures that necessitate greater strength. They are commonly utilized in the construction of high-rise bridges and long-span structures. 4. Grade 80 and Grade 100: These are high-strength steel rebars with minimum yield strengths of 80,000 psi and 100,000 psi, respectively. These grades of steel rebars are used in specialized bridge construction projects that require exceptional strength and durability. They are commonly employed in the construction of cable-stayed bridges and suspension bridges. It is worth noting that the selection of the appropriate grade of steel rebar for bridge construction relies on various factors, including anticipated loads, span length, design specifications, and local building codes. Consulting with structural engineers and adhering to recommended guidelines ensures the utilization of the appropriate grade of steel rebar, thereby guaranteeing the safety and longevity of the bridge structure.

- Q: What is the recommended minimum cover for steel rebars in concrete?

- The recommended minimum cover for steel rebars in concrete is typically around 1.5 inches (38mm) to ensure proper protection against corrosion and provide adequate strength and durability to the structure.

Send your message to us

Hot Rolled Steel Rebars Deformed bar ASTM

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords