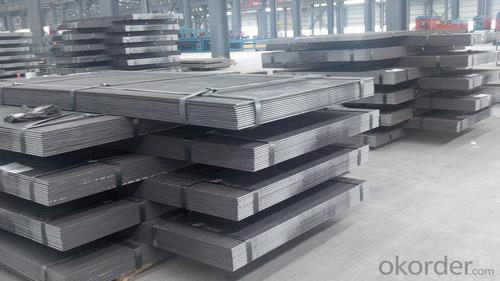

Hot Rolled Steel Plate Q345

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Rolled Steel Plate Q345

1. Hot Rolled & Annealing

2.Good Quality & Fast Delivery

3.Competitive Price & Nice Service

hot rolled steel plate

Standard:ASTM AISI BS GB JIS DIN Thickness:3.0-250mm

Material: S235JR, SS400, S355JR, A36

ASTM A283/A283M-03 Grade D

ASTM A572/A572M-04 Grade 50(345)

JIS G3101-2004 SS400

JIS G3135-1986 SPFC 590

EN 10025/2-2004 S235JR or S235JO or S235J2

EN 10025/2-2004 E335 or S335JR or S335JO or S335JZ or S335KZ or S335NL

Specification:

THICKNESS:2mm-120mm

WIDTH:1250mm-3000mm

LENGTH:1500mm-18000mm

1.0/1.5*1000*C, 1.5*1250/1500*C

2.90*1250/1500*C, 3.75*1250/1500*C

4.50*1250/1500*C, 4.75*1250/1500*C

5.00*1250/1500*C, 5.25*1250/1500*C

5.50*1250/1500*C, 5.75*1250/1500*C

6.00*12501500*C, 7.25*1250/1500*C

7.50*1250/1500*C, 7.75*1250/1500*C

8.0*1250/1500*C

9.25/9.50/9.75/11.25/11.50/11.75*1500*C

High quality: smooth, straight, bright, with no blur on both ends

Feature: Heat conduction, excellent freezing, even structure with pressure resistance, Good mechanical properties

- Q: What is the difference between a brushed and polished steel sheet?

- A brushed steel sheet and a polished steel sheet differ in terms of their surface finishes. A brushed steel sheet is characterized by a pattern of parallel lines or scratches on its surface, created using abrasive materials or tools. The purpose of brushing is to give the steel sheet a textured appearance, which helps to hide fingerprints, scratches, and wear over time. It also provides a more industrial, matte finish. On the other hand, a polished steel sheet has a smooth and glossy surface. Polishing involves using polishing compounds or abrasive materials to remove imperfections, scratches, and oxidation from the steel surface. This process creates a reflective and mirror-like finish, enhancing the aesthetic appeal of the steel sheet. Polished steel sheets are commonly used in applications where appearance and visual appeal are important, such as architectural design, interior decoration, and high-end products. In summary, the main difference between a brushed and polished steel sheet lies in their surface finishes. Brushed steel sheets have a textured, matte appearance, while polished steel sheets have a smooth and glossy, mirror-like finish. The choice between the two depends on the desired aesthetic, functional requirements, and the intended application of the steel sheet.

- Q: What is the hardness of steel sheets?

- The hardness of steel sheets can vary depending on the specific type and grade of steel being used. However, steel sheets are generally known for their high hardness, as they are often heat-treated or alloyed to achieve desired hardness levels.

- Q: What are the maintenance requirements for steel sheets?

- The maintenance requirements for steel sheets typically involve regular cleaning to remove dirt, dust, and other debris. Additionally, applying a protective coating such as paint or galvanization can help prevent corrosion and rust. Inspecting for any signs of damage or wear is also important, and any issues should be addressed promptly to maintain the integrity and longevity of the steel sheets.

- Q: What are the different edge treatments available for steel sheets?

- Some common edge treatments available for steel sheets include sheared edges, deburred edges, rolled edges, chamfered edges, and beveled edges.

- Q: Can steel sheets be used in earthquake-resistant construction?

- Yes, steel sheets can be used in earthquake-resistant construction. Steel has excellent strength and ductility properties that allow it to withstand the forces generated during an earthquake. Additionally, steel sheets can be easily fabricated, assembled, and incorporated into various structural systems, making them a popular choice for earthquake-resistant construction.

- Q: What is the process of applying anti-slip patterns to steel sheets?

- The process of applying anti-slip patterns to steel sheets typically involves a few steps. First, the steel sheets are thoroughly cleaned and prepped to ensure proper adhesion. Then, a layer of primer or adhesive is applied to the surface of the steel sheet. Next, a patterned sheet or plate is pressed onto the adhesive, creating a textured surface. The sheets are then allowed to dry or cure, depending on the type of adhesive used. Finally, the finished steel sheets with anti-slip patterns are inspected for quality and readiness for use in various applications.

- Q: How are steel sheets protected against rusting?

- Steel sheets are protected against rusting through a process called galvanization. This involves coating the steel sheets with a layer of zinc, which acts as a protective barrier against moisture and oxygen, preventing rust formation. Additionally, other methods such as painting or applying corrosion-resistant coatings can also be used to further enhance the protection against rusting.

- Q: Are steel sheets suitable for manufacturing water pipes?

- Yes, steel sheets are suitable for manufacturing water pipes. Steel is a durable and strong material that can withstand high pressure and corrosion, making it an ideal choice for water pipes. Steel sheets can be easily formed and welded together to create seamless pipes that are resistant to leaks. Additionally, steel pipes have a long lifespan and require minimal maintenance, making them a cost-effective option for water pipe manufacturing.

- Q: What are the different standards and certifications for steel sheets?

- Steel sheets must adhere to numerous standards and certifications in order to ensure their quality and compliance with industry requirements. Some of the well-known ones are: 1. ASTM International: To establish the mechanical and chemical properties of steel sheets, ASTM A1008/A1008M provides a standard specification for cold-rolled, carbon, structural, high-strength low-alloy steel sheets with improved formability. 2. American Iron and Steel Institute (AISI): Various standards are offered by AISI for different types of steel sheets, such as AISI 4130, AISI 4140, AISI 4340, etc. These standards outline the chemical composition, mechanical properties, and heat treatment requirements for specific steel sheet types. 3. International Organization for Standardization (ISO): ISO has developed standards like ISO 3574, ISO 630, and ISO 4998 to cover dimensional tolerances, mechanical properties, and technical delivery conditions for specific steel sheet grades. 4. European Committee for Standardization (CEN): CEN has defined requirements for cold-rolled, hot-rolled, and high-strength steel sheets through standards like EN 10130, EN 10025, and EN 10149 respectively. These standards encompass aspects such as chemical composition, mechanical properties, and surface finish. 5. Japan Industrial Standards (JIS): JIS standards like JIS G 3141, JIS G 3131, and JIS G 3132 are widely used for cold-rolled, hot-rolled, and hot-rolled high-strength steel sheets respectively. They specify the mechanical properties, chemical composition, and dimensional tolerances of steel sheets. Furthermore, steel sheet manufacturers can obtain various certifications to demonstrate their adherence to specific quality and environmental management systems. Some widely recognized certifications in the steel industry include ISO 9001 (Quality Management System), ISO 14001 (Environmental Management System), and OHSAS 18001 (Occupational Health and Safety Management System). These certifications guarantee that manufacturing processes and products meet the required standards while being produced in an environmentally sustainable and safe manner.

- Q: Are steel sheets suitable for railway track construction?

- Yes, steel sheets are suitable for railway track construction. Steel is a highly durable and strong material, making it ideal for withstanding the heavy loads and constant traffic of trains. Steel sheets are often used as the base for railway tracks, providing a solid foundation for the rails and ensuring stability and reliability. Additionally, steel offers excellent resistance to wear, corrosion, and deformation, which are crucial factors in maintaining the long-term performance of railway tracks. Its high strength-to-weight ratio also allows for lighter track structures and reduced maintenance requirements. Overall, steel sheets are a popular choice in railway track construction due to their strength, durability, and cost-effectiveness.

Send your message to us

Hot Rolled Steel Plate Q345

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords