Hot Rolled Steel Coils Q235 Carbon Steel Steel Sheets Made In China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

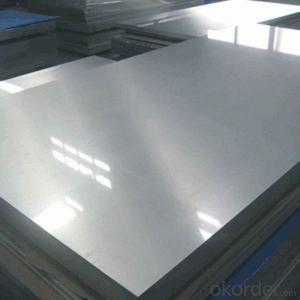

DESCRIPTION FOR SS400 CARBON STEEL SHEET

1.Thickness: 1-200mm

2.Width: 100-3000mm

3.Length: 1000-12000mm

4. Applications :mining machinery, environmental protection, engineering

5. Grade:SS400 A 36 Q195.Q235.Q345.SPCC.SPCH

6.Surface : Hot Rolled Cold Rolled Galvanized Steel

DESCRIPTION FOR CARBON STEEL PLATE

Production | hot rolled st eel coils ss400 |

Port | Tianjin, China |

Category | Minerals & metallurgy |

Thickness | 1.8-16mm |

Width | 1000-1500mm |

Coil Weight | about 23 tons |

Material Grade | SS400\Q235\Q345B |

Technique | Hot Rolled |

Standard | GB ,JIS |

Test | With Hydraulic Testing, Eddy Current , Infrared Test |

Surface | 1) Bared 2) Black Painted (varnish coating) 3) Galvanized 4) Oiled |

Package | in bundles, strapped by strips. Or as customer’s requirement |

Sample | Common products, we can provide freely, for special production,we can depends on negotiation. |

MOQ | 50 tons |

Payment | 100% L/C at sight, 30% T/T in advance, and the balance against the copy of B/L or negotiation |

Delivery time | Within 10-25 days, according to quantity, asap save customer’s time |

Certificate | ISO |

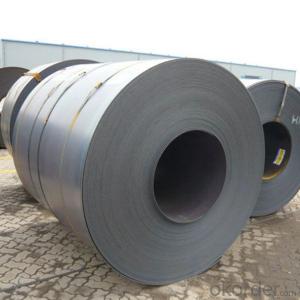

DETAILED PICTURES FOR STEEL COILS

PACKING:

1.Big thickness:by bulk vessel

2.Small thickness:packed by steel strips and shipped by container

3.According to the requirements of customers'

TRADE TERMS :FOB, CFR, CIF

FAQ:

Q:How about the trade terms?

A:EXW,FOB,CFR,CIF will be accepted.

Q:How about your payment terms?

A:30%TT in advance and the balance against of copy of B/L.The irrevocable L/C at sight will be accepted.

- Q: How is steel sustainable as a building material?How is wood sustainable as a building material?

- In okorder /.. Properly managed then wood is a fully sustainable and green building material and from an environmental perspective is better than steel. However, it doesn’t possess the compressive strength that steel possesses and it can’t easily be worked or formed into structural components like steel can.

- Q: How are steel coils used in the manufacturing of building materials?

- Due to their strength, durability, and versatility, steel coils find wide application in the production of building materials. Typically, these coils are made from high-quality steel and shaped into a continuous, flat strip. One of the primary uses of steel coils in building materials involves manufacturing steel roofing and siding. To achieve the desired dimensions and profiles, the coils undergo a series of processes that involve cutting, shaping, and rolling the steel. Consequently, the resulting roofing and siding materials are highly durable and resistant to weather, enabling the construction of long-lasting building envelopes. Additionally, steel coils are essential in the production of steel studs, which are crucial components for constructing frameworks. By cutting and forming the coils into precise shapes, they are assembled to create sturdy and rigid frameworks for walls, ceilings, and other structural elements. Notably, steel studs offer various advantages such as a high strength-to-weight ratio, fire resistance, and dimensional stability, making them a popular choice within the construction industry. Apart from roofing, siding, and framing, steel coils are utilized in the manufacturing of various other building materials. These materials encompass steel pipes, beams, columns, and reinforcement bars, which are indispensable for constructing foundations, infrastructure, and structural elements. Furthermore, steel coils serve as raw materials for fabricating metal panels, doors, windows, and other architectural components. In summary, steel coils play an indispensable role in manufacturing building materials due to their provision of necessary strength and durability for robust and long-lasting structures. Their versatility enables the production of a wide range of building components, cementing steel coils as an invaluable resource within the construction industry.

- Q: How are steel coils used in the production of metal furniture?

- Steel coils are used in the production of metal furniture as the primary raw material for shaping and forming various components such as frames, legs, and supports. These coils are unrolled and cut into appropriate lengths, then undergo processes like bending, welding, and shaping to create the desired furniture pieces. The strength, durability, and malleability of steel make it an ideal material for constructing sturdy and long-lasting metal furniture.

- Q: How are steel coils used in the manufacturing of steering systems?

- Steel coils are used in the manufacturing of steering systems as they provide the necessary strength and durability required for the components of the system, such as steering columns, gears, and shafts. These coils are shaped and formed into various parts through processes like cutting, bending, and welding, ultimately contributing to the overall stability and functionality of the steering system in vehicles.

- Q: Alright, First off i have an old plywood military box with galvanised steel corners, hinges etc (any part that must be strong) and its rusting! Some of the pieces have discoloration (like an oil stain on them) and other parts are full of this metallic dust. 1) Should i remove this box from my room?2) Is there any way or should i remove the powder on the part?3) Does this pose a serious health hazard?4) What are the oil stains?

- Dear HC, You have a great military box and a cool conversation piece. Take a vacuum and clean the dust. Take some 0000 steel wool and use on the steel parts. This will take some elbow grease! If this doesn't work try some 320 grit sand paper. lightly sand the wood and brush polyurethane on everything . The box doesn't pose any health problems. Also you might find that the box will bring a pretty good price if you decide to sell. Good luck. Sniper

- Q: LIke a steel building conversion into a residental building??? Thanks.

- Right here. Steel Homes, Steel House, Steel Buildings, Steel Home Plans, ... Steel Homes, Steel House, Steel Buildings, Steel Home Plans, Steel Houses, ... Steel Homes and Buildings · Steel Office Buildings and Construction sites ... www.karmod.eu/steel-structures - 18k - Similar pages www.karmod.eu/steel-structures steel buildings metal buildings modular homes steel building ... ... log homes photographs, log homes construction, sales agents, log homes financing, ... Easy online pricing

- Q: What are the advantages of using steel coils?

- There are several advantages of using steel coils. Firstly, steel coils offer superior strength and durability, making them suitable for various applications in industries such as construction, automotive, and manufacturing. Secondly, steel coils have excellent resistance to corrosion, ensuring longevity and reducing maintenance costs. Additionally, steel coils can be easily shaped or formed into different sizes and shapes, providing flexibility in design and manufacturing processes. Lastly, steel coils are recyclable, making them an environmentally friendly choice and contributing to sustainable practices.

- Q: How are steel coils used in the production of steel plates?

- Steel coils are a critical component in the production of steel plates. They serve as the primary raw material for manufacturing steel plates. The process begins with the production of steel coils, which are created by heating and cooling molten steel to form thin, flat strips. These coils are then processed further in a rolling mill, where they are passed through a series of rollers to reduce their thickness and increase their length. Once the desired dimensions are achieved, the steel coils are then uncoiled and straightened. This process involves feeding the coils through a machine that removes any curvature or deformities, ensuring the strips are completely flat. The straightened coils are then cut into specific lengths to suit the required dimensions of the steel plates. After being cut, the coils undergo another crucial step known as leveling. This process involves passing the strips through a leveling machine, which eliminates any residual stress or warping that may have occurred during the production process. Leveling ensures that the steel plates have a uniform thickness and are free from any distortions, making them suitable for various applications. Once the leveling process is complete, the steel coils are finally transformed into steel plates. These plates can be further processed based on the desired end-use. They may undergo additional treatments such as heat treatment, surface finishing, or coating to enhance their strength, durability, and corrosion resistance. In summary, steel coils are the starting point for the production of steel plates. They undergo several crucial steps, including rolling, uncoiling, straightening, cutting, and leveling, to transform them into flat, uniform steel plates. These plates can then be further processed and customized for a wide range of applications in industries such as construction, automotive, shipbuilding, and manufacturing.

- Q: How are steel coils used in the manufacturing of railway bridges?

- Steel coils are used in the manufacturing of railway bridges as they are transformed into structural components such as beams, plates, and girders. These coils are processed and shaped into the desired forms, providing the necessary strength and durability for the bridge's construction.

- Q: What is the role of steel coils in the manufacturing of storage racks?

- Steel coils play a crucial role in the manufacturing of storage racks as they are used as the primary material for constructing the frame and shelves of the racks. The coils are processed and cut into specific dimensions to form the structural components and provide strength and stability to the storage racks.

Send your message to us

Hot Rolled Steel Coils Q235 Carbon Steel Steel Sheets Made In China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords