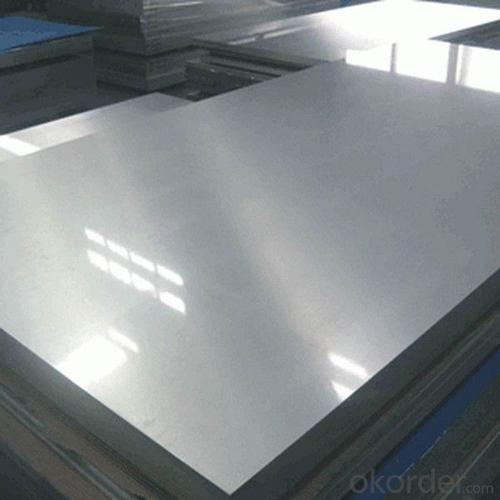

Q235 Cold Rolled Steel Plate/ Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Q235 Cold Rolled Steel Plate

Product Description

Product name: Cold rolled steel plate

Product Description

.1)Thickness: 0.4-3.0mm

2)Width: 600/1000/1250/1500mm or customized

3)Grade: SPCC, SPCD, SPCE, DX51D+Z, DC01-06, ST12, 170P1, HC380LA, SPHC, Super deep drawing

4)Standard: JIS G3141-1996, EN 10131-2006, DIN EN 1002

5)Weight of Cold Rolled Coil : 3-15MT

6)Surface Treatment: Galvanized or Oil

7)Technique: Cold rolled

8)Edge: Cut edge or Mill

9)Original place: Shandong, China

10)Advantage of Cold Rolled Coil :

High quality in flatness, brightness and straightness, and be qualified in both chemical compositions and mechanical properties.

11) Package of Cold Rolled Coil : Strapped with min three strapping strips, covered by anti-water paper and plastic film, fixed on the iron or wooden pallets by strapping strips and covered by plastic bag to prevent damage from transportation.

12)Applications for Cold Rolled Coil :(1) For the further producing of hot dip galvanized steel products or Prime Pre-painted Steel Coil

(2) Cold rolled Steel Coil: Auto manufacture, Oil drum, Transformer's tank panel, Furniture, bicycle, construction, battery case, industrial machine, etc.

13)Process of Cold Rolled Coil :

Pickling: To clean the dust and rust points on the surface.

Cold Rolling: Digital rolling control system produces minimum thickness tolerance, helps to prevent twist and improve straightness.

Slitting: Precise slitting machinery helps control the best width tolerance and avoid camber or cracker.

- Q: What is the difference between a painted and powder coated steel sheet?

- The main difference between a painted and powder coated steel sheet lies in the application process. Painted steel sheets involve applying liquid paint onto the surface, which can result in a thinner and less durable coating. On the other hand, powder coated steel sheets involve electrostatically applying dry powder onto the surface, followed by curing in an oven, resulting in a thicker and more durable coating. Powder coating also offers better resistance to chipping, scratching, and fading compared to traditional paint.

- Q: Can steel sheets be painted after installation?

- After the installation, it is possible to paint steel sheets for aesthetic improvement and protection against rust and corrosion. However, before applying paint, it is crucial to ensure that the surface is clean and devoid of any pollutants. Adequate preparation, such as cleaning and sanding, is necessary to promote adhesion and achieve a durable finish. It is advisable to use a primer specifically formulated for steel surfaces before applying the desired paint color. Moreover, selecting a high-quality paint suitable for exterior or industrial use will yield optimal results and longevity.

- Q: Can steel sheets be used for mezzanine flooring?

- Yes, steel sheets can be used for mezzanine flooring. Steel sheets offer several advantages for mezzanine flooring, including their strength, durability, and versatility. Steel sheets are able to withstand heavy loads and provide a stable and reliable flooring solution. Additionally, they can be easily customized to fit specific dimensions and requirements, making them adaptable for different mezzanine designs. Steel sheets are also resistant to fire, moisture, and pests, ensuring a long-lasting and low-maintenance flooring option. Overall, steel sheets are a popular choice for mezzanine flooring due to their strength, durability, and flexibility.

- Q: What are the different grades of steel sheets?

- There are several different grades of steel sheets, which are classified based on their chemical composition, strength, and other properties. Some common grades include mild steel, stainless steel, high-strength low-alloy (HSLA) steel, and galvanized steel. Each grade has specific characteristics that make it suitable for different applications and industries.

- Q: Are steel sheets resistant to humidity?

- Yes, steel sheets are generally resistant to humidity as they do not absorb moisture or expand in the presence of high humidity levels.

- Q: Are the steel sheets available in different thickness tolerances?

- Certainly, there are various thickness tolerances for steel sheets that are readily available. Steel producers create sheets with diverse thicknesses to accommodate different purposes and demands. These tolerances are determined by established standards within the industry and can differ based on the steel type and intended application. In construction, for instance, tighter tolerances might be mandatory to guarantee the structural soundness, while in manufacturing sectors like automotive or aerospace, precise tolerances may be indispensable to meet design requirements. Through offering steel sheets in varying thickness tolerances, manufacturers allow customers to select the most fitting product for their individual requirements.

- Q: Are steel sheets suitable for modular construction?

- Yes, steel sheets are suitable for modular construction. They are lightweight, durable, and have high strength-to-weight ratio, making them ideal for constructing modular buildings. Steel sheets can be easily fabricated and assembled into modular components, providing flexibility and ease of construction. Additionally, steel is resistant to fire, pests, and weathering, ensuring longevity and safety in modular structures.

- Q: Can the steel sheets be easily cleaned?

- Yes, steel sheets can be easily cleaned. Steel is known for its durability and ease of maintenance. It can be wiped clean using a damp cloth or sponge with mild soap or detergent. For tougher stains or grime, a non-abrasive cleaner can be used. Additionally, steel sheets are resistant to rust and corrosion, making them suitable for various environments and easy to maintain in the long run.

- Q: How do steel sheets compare to fiberglass sheets?

- Steel sheets and fiberglass sheets have distinct characteristics that make them suitable for different applications. Steel sheets are known for their high strength and durability. They are capable of withstanding heavy loads and have excellent resistance to impact and abrasion. Steel sheets also offer exceptional fire resistance, making them ideal for applications where fire safety is a concern. Furthermore, steel sheets are relatively low maintenance and can withstand harsh weather conditions, making them a popular choice for outdoor structures such as roofing and siding. On the other hand, fiberglass sheets are lightweight and have excellent corrosion resistance. They are typically made from woven glass fibers embedded in a resin matrix, which gives them high strength-to-weight ratio. Fiberglass sheets are also non-conductive, making them suitable for applications where electrical insulation is required. Additionally, fiberglass sheets are highly transparent to electromagnetic waves such as radio waves, making them commonly used in industries such as telecommunications. While steel sheets offer superior strength and are better suited for heavy-duty applications, fiberglass sheets excel in areas where weight, corrosion resistance, and electrical insulation are important factors. Ultimately, the choice between steel sheets and fiberglass sheets depends on the specific requirements of the application and the desired characteristics needed to fulfill those requirements.

- Q: What are the different testing methods for steel sheets?

- There are several testing methods for steel sheets, including visual inspection, hardness testing, tensile testing, impact testing, bend testing, and ultrasonic testing. Visual inspection involves examining the surface for any visible defects or imperfections. Hardness testing measures the resistance of the steel to indentation, which can indicate its strength and durability. Tensile testing evaluates the steel's ability to withstand pulling forces, while impact testing measures its resistance to sudden shocks or impacts. Bend testing assesses the steel's flexibility and ability to withstand deformation. Ultrasonic testing uses sound waves to detect internal flaws or defects in the steel. These methods are commonly used to ensure the quality and reliability of steel sheets in various industries.

Send your message to us

Q235 Cold Rolled Steel Plate/ Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords