Hot Rolled Steel Coil with Standard ASTM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details

Basic Info.

Model NO.:cm-191

Standard:ASTM, JIS, GB

Steel Grade:Q235

Certification:ISO

Surface Treatment:Coated

Technique:Hot Rolled

Stock:Stock

Export Markets:Global

Additional Info.

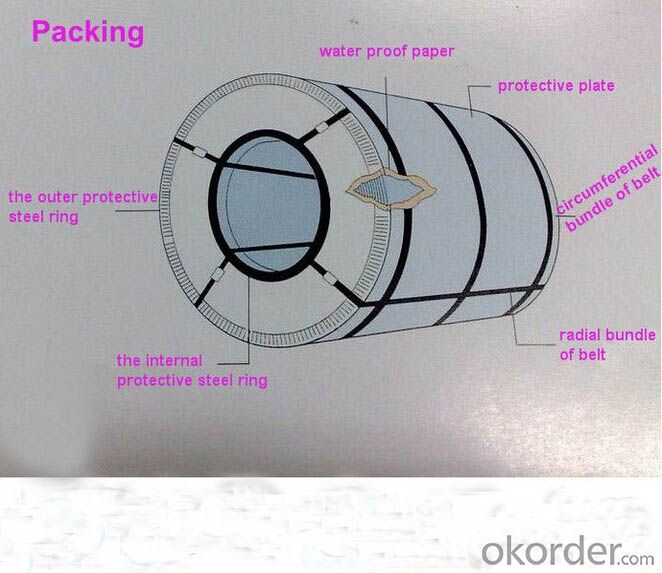

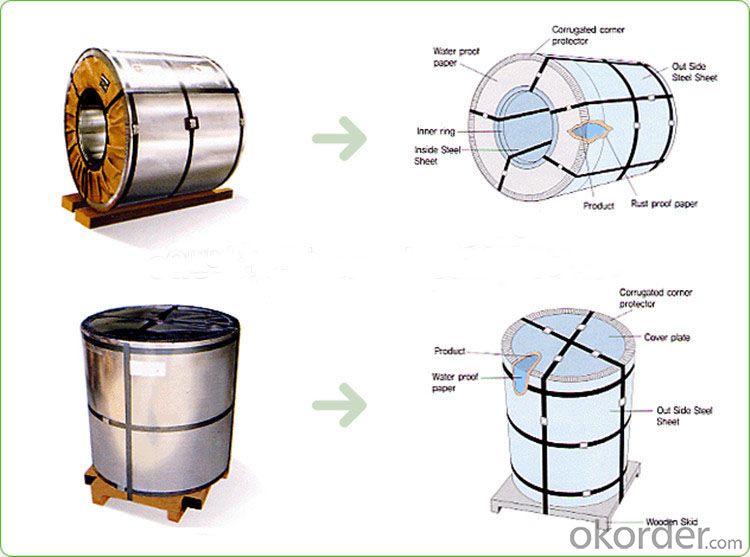

Packing:in Bundles

Origin:China

Production Capacity:100, 000mt/Year

Product Description

Hot Dipped Galvanized Steel Coil

JISG3302/ DX51D

SGCC/ SGCH

Full Hard/ Soft

Regular spangle/ Big spangle/ Small Spangle

Chromated

Unoiled

Z60/Z80/Z100/Z120/Z150/Z180/Z275

Thickness: 0.12-3.0mm

Width: 610-1250mm

FAQ:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4.What is the validity of your quotation?

Normally 7 days.

5.What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

- Q: I was looking at my Great-Grandfather's immigration form from when he immigrated from Scotland and he listed his occupation as a steel dresser. What does a steel dresser do?

- I'm not sure, but it could be like and engineer working in steel design or steel polisher. I checked Wikipedia and Yahoo but found nothing. It may be a description of something only in Scotland. Sorry

- Q: I recently got in a car accident with a steel mailbox, on a snowy day. I was wondering if i can do anything since the steel mailbox caused my car to be totaled. Otherwise it would have been fine and would have suffered only minor damage. Anything I can do here to maybe get some money back? Thanks!

- Let me get this straight. You were driving too fast for conditions, lost control due to driving too fast, hit a stationary mailbox, car is totaled due to driving too fast for conditions, and you want to be reimbursed? Sorry, you are dead wrong. It is your duty to maintain control of your car at all times. If there was any damage to the mailbox, you are the one liable.

- Q: What are the factors affecting the lifespan of steel coils?

- There are several factors that can affect the lifespan of steel coils, including the quality of the steel used, the level of protection against corrosion, the storage and handling conditions, the frequency and severity of mechanical stress, and the effectiveness of maintenance and preservation practices.

- Q: How are steel coils used in the production of industrial storage tanks?

- Steel coils are commonly used in the production of industrial storage tanks due to their superior strength and durability. These coils are typically made from high-quality steel that is rolled into a coil shape, allowing for easy transportation and handling. In the production process, steel coils are first uncoiled and flattened to create sheets of steel. These sheets are then cut and formed into the desired shape and size for the storage tank. The steel sheets are welded or bolted together to create the tank's body, which is designed to withstand high pressure and heavy loads. The use of steel coils in the production of industrial storage tanks offers several advantages. Firstly, the strength and durability of steel ensure that the tanks can withstand harsh conditions and are resistant to corrosion. This is particularly important for storage tanks that may contain corrosive substances or be exposed to harsh environments. Additionally, the flexibility of steel coils allows for customization of the tank's design and size. This is particularly beneficial in industries where storage requirements can vary significantly, such as the oil and gas industry. Steel coils can be easily cut and formed into various shapes and sizes, enabling the production of storage tanks that meet specific storage needs. Furthermore, steel coils can be easily transported and stored, making them a cost-effective choice for the production of industrial storage tanks. The coils can be efficiently transported to the manufacturing facility, reducing transportation costs and logistical complexities. Overall, steel coils play a crucial role in the production of industrial storage tanks by providing strength, durability, and customization options. Their use ensures that the tanks can safely store and protect various substances, making them essential for a wide range of industries.

- Q: How are steel coils inspected for camber using laser profiling?

- Steel coils are inspected for camber using laser profiling, which is a non-contact measurement technique. Laser profiling involves the use of a laser beam that is emitted onto the surface of the steel coil. As the laser beam moves across the coil, it creates a profile of the coil's surface, capturing precise measurements. To inspect for camber, the laser profiling system scans the entire length and width of the coil, capturing data points at regular intervals. These data points are then analyzed to determine the deviation from a straight line, which indicates the presence of camber. During the inspection process, the laser profiling system compares the measured profile of the steel coil to a reference profile, which represents an ideal or straight surface. The deviation between the measured profile and the reference profile is calculated, and if this deviation exceeds a predetermined threshold, the coil is flagged as having camber. Laser profiling offers several advantages for inspecting steel coils for camber. Firstly, it provides a non-contact measurement, eliminating the need for physical contact with the coil and reducing the risk of damage. Additionally, laser profiling is highly accurate, capable of capturing even small deviations in the coil's surface. This ensures that camber is detected reliably, allowing for necessary corrective actions to be taken. Overall, the use of laser profiling for inspecting steel coils for camber ensures efficient and accurate detection of this defect, enabling manufacturers to maintain high-quality standards and deliver reliable products to customers.

- Q: How are steel coils used in the production of construction equipment?

- Steel coils are used in the production of construction equipment as they are a crucial raw material for manufacturing various components such as frames, beams, plates, and structural parts. These coils are processed through cutting, bending, and welding techniques to form the required shapes and structures used in the construction industry.

- Q: How are steel coils cleaned?

- Steel coils are typically cleaned using a combination of chemical and mechanical processes. The coils are first treated with a degreasing agent to remove any oil or grease present on the surface. Then, high-pressure water jets or brushes are used to scrub away any remaining dirt or contaminants. The coils may also undergo a rinsing process to ensure all cleaning agents are removed. Additionally, some manufacturers may use acid cleaning or pickling techniques to remove scale or rust from the surface of the coils.

- Q: and what type of metal is steel?

- Steel is an alloy consisting mostly of iron, with a carbon content between 0.2% and 2.14% by weight (C:110–10Fe), depending on grade. Carbon is the most cost-effective alloying material for iron, but various other alloying elements are used such as manganese, chromium, vanadium, and tungsten. Carbon and other elements act as a hardening agent, preventing dislocations in the iron atom crystal lattice from sliding past one another. Varying the amount of alloying elements and form of their presence in the steel (solute elements, precipitated phase) controls qualities such as the hardness, ductility, and tensile strength of the resulting steel. Steel with increased carbon content can be made harder and stronger than iron, but is also more brittle.

- Q: How are steel coils used in the production of wind turbines?

- Steel coils are used in the production of wind turbines to manufacture the tower, nacelle, and other structural components. The coils are processed and shaped to form the required sections, which are then assembled and integrated to create the framework and support structure for the wind turbine. The high strength and durability of steel make it an ideal material for withstanding the demanding conditions and loads experienced by wind turbines.

- Q: What is the current value of steel? Is it expected to increase in value?

- The steel in steel cents is the same as the steel in soup cans you throw out all the time. There is no sense in holding steel cents for their value as scrap. There are way too many steel cents around for them to ever have much numismatic value.

Send your message to us

Hot Rolled Steel Coil with Standard ASTM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords