Hot Rolled Steel Coils with Standard ASTM

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Rolled to its final dimensions while it’s hot enough to scale, our hot-rolled steel is an amalgamation of the various qualities of steel.

It can be in the form of plates, sheets and coils.

Our hot rolled steel sheets and coils are applied to wide range of uses such as automobile, electrical appliance, machinery manufacturing, container manufacturing, shipbuilding bridge, pipeline, and receive high acclaim from our customers for its excellent quality.

Specification of Hot Rolled Steel Coils with Standard ASTM

Standard:ASTM, JIS, GB

Steel Grade:Q235

Technique:Hot Rolled

Packing:in Bundles or Coils

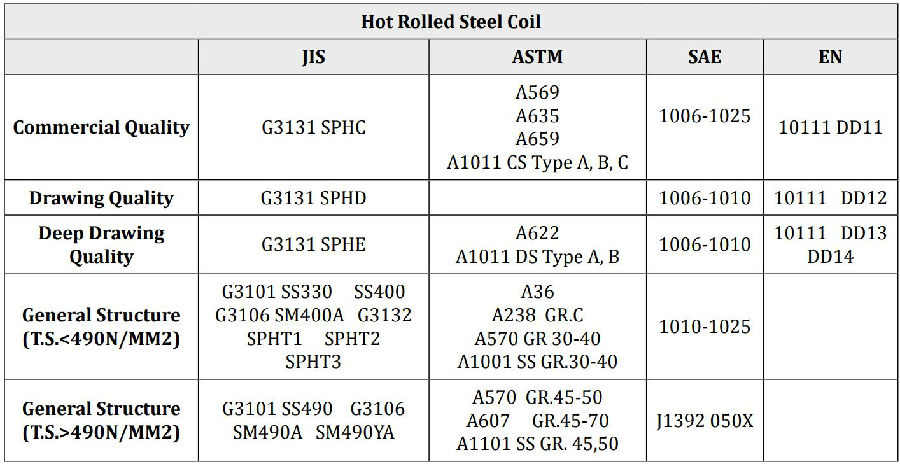

STANDARD & GRADE

APPLICATION

Automobile, Electrical Appliance, Machinery, Transport Equipment, Steel Structure, Pressure Vassel Tank, Welded Pipe, Bridge, Container Shipbuilding.

FAQ:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size.

And we will consider to give more discount if you make big order like 1000 tons and more.

Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC.

We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;

We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

4.What is the validity of your quotation?

Normally 7 days.

5.What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

- Q: How are steel coils used in the manufacturing of oil and gas equipment?

- Steel coils are commonly used in the manufacturing of oil and gas equipment due to their durability and strength. They are typically formed into various shapes and sizes to create components such as pipes, tanks, valves, and fittings. These coils are processed and fabricated into these equipment to withstand the demanding conditions of the oil and gas industry, including high pressures, corrosive environments, and extreme temperatures.

- Q: I am looking to weld some stainless steel using stainless electrodes. I was told that the arc welder needs to be able to run in DC in order to be able to weld stainless steel. Is this true? Or can you weld stainless steel with stainless electrodes with AC also?

- Arc or stick welding is not ideal for stainless steel. It is advisable to use MIG or TIG welding instead, with argon shield gas. I would only advise manual arc welding as a last resort, or for field repairs. Expect corrosion issues, and issues with excessive oxidation and porosity in your stainless welds. Manual arc welding is a dirty process and simply does not protect the weld puddle well enough from oxidation and carbon pickup, which are especially damaging in sensitive stainless alloys. As to whether to use AC or DC for stick welding, you should consult the instructions found on the box of electrodes. If polarity and current recommendations cannot be found, then you should contact the manufacturer and get it in writing. You should probably not make welding decisions based on advice from a sales representative. Firstly is is not documented. Secondly, sales representatives are not legally liable for damages caused by weld failures, YOU are.

- Q: What are the environmental considerations of using steel coils?

- There are several environmental considerations associated with using steel coils. Firstly, the production of steel coils requires a significant amount of energy and raw materials, which can contribute to greenhouse gas emissions and environmental degradation. Additionally, the extraction and processing of iron ore for steel production can have negative impacts on land, water, and air quality. Moreover, the transportation of steel coils, especially over long distances, can result in emissions from vehicles and contribute to pollution. Lastly, the disposal of steel coils at the end of their lifecycle poses challenges as they can be difficult to recycle and may end up in landfills, further contributing to waste accumulation. Overall, the environmental implications of using steel coils highlight the need for sustainable practices in their production, transportation, and disposal.

- Q: What are the different types of surface treatments for steel coils?

- There are several types of surface treatments for steel coils, including galvanizing, painting, and coating. Galvanizing involves applying a layer of zinc to protect the steel from corrosion. Painting involves applying a layer of paint to provide both corrosion resistance and aesthetic appeal. Coating involves applying a thin layer of protective material, such as polymer or epoxy, to enhance the steel's durability and resistance to corrosion. These surface treatments are chosen based on the specific requirements of the steel coils and the desired end-use applications.

- Q: Already on my team is Empoleon lvl 82Heatran lvl 74Scizor lvl 34Magnezone lvl 38What other steel types should I choose?

- Skarmory, Steelix, Metagross, or Bastiodon. Personally I would switch Heatran, as I don't feel right using Legendaries.

- Q: Can steel coils be coated with vibration-damping materials?

- Yes, steel coils can be coated with vibration-damping materials.

- Q: How are steel coils processed into finished products?

- Steel coils are processed into finished products through a series of steps including uncoiling, leveling, cutting, shaping, and surface treatment. The uncoiling process involves unwinding the steel coil to create a flat sheet. Next, leveling machines remove any unevenness in the sheet's surface. Then, the sheet is cut into desired lengths or shapes using cutting machines. Shaping processes such as bending, rolling, or stamping are performed to achieve the desired product form. Finally, surface treatment techniques like galvanizing, painting, or coating are applied to enhance the product's durability and appearance.

- Q: What are the different types of steel coil cutting blades?

- There are several different types of steel coil cutting blades, each designed for specific cutting applications. 1. Slitting Blades: Slitting blades are used for cutting steel coils into narrow strips. They typically have a straight cutting edge and are available in various widths to accommodate different slitting requirements. These blades are commonly used in industries such as automotive, construction, and metal fabrication. 2. Shearing Blades: Shearing blades are designed for cutting steel coils into flat sheets. They have a curved cutting edge that facilitates a clean and precise cut. Shearing blades are commonly used in steel service centers, where large coils are processed into flat sheets for further manufacturing processes. 3. Circular Blades: Circular blades, also known as rotary blades, are used for cutting steel coils in a continuous motion. These blades have a circular shape with sharp teeth around the edge, enabling them to cut through the coil as it passes through the cutting machine. Circular blades are commonly used in industries such as packaging, printing, and paper manufacturing. 4. Guillotine Blades: Guillotine blades are used for cutting steel coils with a straight downward motion. These blades have a straight cutting edge that moves vertically to cut through the coil. Guillotine blades are commonly used in heavy-duty cutting applications, such as cutting thick steel coils or large quantities of material. 5. Slitter Knives: Slitter knives are similar to slitting blades but are typically smaller and used in slitting machines that require multiple blades. They are often used in industries that require high-precision slitting, such as the production of electrical transformers or precision metal stamping. Each type of steel coil cutting blade has its own unique design and characteristics that make it suitable for specific cutting tasks. The selection of the appropriate blade depends on factors such as the thickness and width of the steel coil, the desired cut quality, and the specific application requirements.

- Q: Why people prefer prefabricated buildings these days? Recently my friend has told me that he is going to owe a steel house so I was just thinking are these steel structures really durable and cheaper than concrete structures?

- Hi., I think steel is the best option for the building ..

- Q: How do steel coils contribute to earthquake resistance in structures?

- Steel coils contribute to earthquake resistance in structures by providing strength and flexibility. When incorporated into the structural design, steel coils can absorb and dissipate the energy generated during an earthquake, reducing the impact on the building. This helps prevent the structure from collapsing or suffering major damage. Additionally, steel coils enhance the overall stability and rigidity of the building, making it more resistant to seismic forces.

Send your message to us

Hot Rolled Steel Coils with Standard ASTM

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords